Friction-stir welding between AA5454 Al alloy and AZ91 Mg alloy

Purpose: Learn to perform complicated multi-component vertical section calculations and understand the application of zero phase fraction (ZPF) line of the liquid phase. Commercial Mg database is required to perform the calculation of this example.

Module: PanPhaseDiagram

Thermodynamic Database: PanMg.pdb(this database is a thermodynamic database for multi-component magnesium alloys which is only available to users who have licensed it.)

Due to the formation of brittle intermetallic phases in the fusion zone, joining Mg alloys with Al alloys through fusion welding is not very suitable. Friction stir welding (FSW) provides a potential method for joining Mg alloys and Al alloys. In this example, an AZ91 cast Mg alloy and rolled AA5454 Al alloy are assumed to be jointed through FSW. A vertical section from the composition of AZ91 to AA5454 shows the possible intermetallic phases could be formed in the welding interface. In addition, the zero phase fraction (ZPF) line of the liquid phase indicates the maximum temperature that can be tolerated during the welding process to avoid the melting zone in the interface. In Pandat™ , The ZPF line the liquid phase can be output through function "f(@Liquid) = 0" in the table.

Calculation Procedures:

-

Load PanMg.pdb following the procedure in Pandat User's Guide: Load Database , and select all three components;

-

Perform 2D calculation following the procedure in Pandat User's Guide: Section Calculation (2D) ;

-

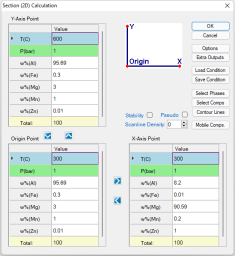

Set Calculation Condition as shown in Figure 1;

Figure 1: Set vertical section calculation conditions: Composition from AA5454: Al-3Mg-1Mn-0.3Fe-0.01Zn(wt.%) at left edge to AZ91: Mg-8.2Al-1Zn-0.2Mn-0.01Fe (wt.%) at right edge; Temperature range from 300 °C to 500 °C

Post Calculation Operation:

-

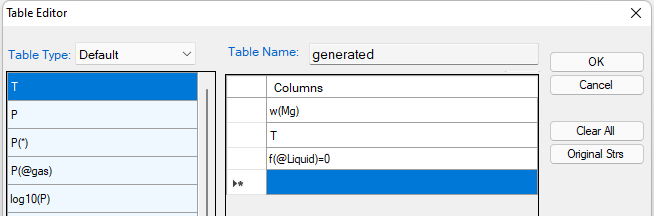

Add a new Table as shown in Figure 2 to get the ZPF line data of the liquid phase (f(@Liquid)=0);

-

Plot the ZPF line data in the added table into the default graph following the procedure in Pandat User's Guide: Table Column Operations;

-

Label phase field following the procedure in Pandat User's Guide: Icons for Graph on Toolbar;

-

Change graph appearance following the procedure in Pandat User's Guide: Property;

Information obtained from this calculation:

-

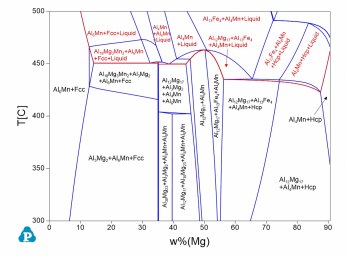

The obtained phase diagram is shown in Figure 3. The local temperatures in the welding zone during friction-stir welding process should be controlled to be lower than given by the red line to avoid partial melting. The lowest temperature in this case is 435.7 °C.

-

Different intermetallic phases may form in the joining zone: The Al3Mg2 phase with some Al6Mn precipitate near the Al alloy side, and Mg17Al12 phase with minor precipitation of Al4Mn near the Mg alloy side.

-

Similar approach can also be used to understand other reactions between different materials, for example coating/substrate reactions.