Simulation of Softening of Aluminum Alloy 6005

Purpose: Learn to calculate the particle size, number density and hardness of aluminum alloy 6005 during ageing and reheating

Module: PanEvolution

Thermodynamic and Mobility Database: AlMgSi.tdb

Kinetic Parameters Database: AA6xxx.kdb

Batch file: Example_#3.5.pbfx

Calculation Procedures:

-

Create a workspace and select the PanEvolution module following Pandat User's Guide: Workspace ;

-

Load AlMgSi.tdb following the procedure in Pandat User's Guide: Load Database ;

-

Click on PanEvolution/PanPrecipitation on the menu bar and select "Load KDB or EKDB", then select the AA6xxx.kdb;

-

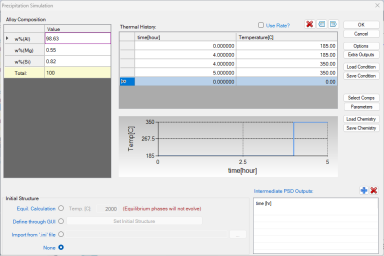

Click on the menu "PanEvolution/PanPrecipitation → Precipitation Simulation", and set up the calculation condition as shown in Figure 1.

Figure 1: Setup heat treatment condition as ageing at 185°C for four hours and then quickly heat up to 350°C and hold for 1 hour

Post Calculation Operation:

-

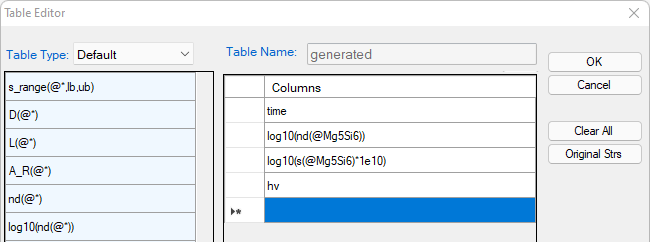

Create a new table as shown in Figure 2, and plot the time vs. log10(nd), time vs. log(size), and time vs. hv;

-

Right Click on the Table node below the Graph and choose "Import Table from File", import table: AA6005-reheat_exp.dat;

-

Plot the experimental data in the corresponding plot by drag in the x-axis and then press Ctrl and drag in the y-axis of the experimental data table;

-

Change graph appearance following the procedure in Pandat User's Guide: Property;

-

Add legend for graph following the procedure in Pandat User's Guide: Icons for Graph on Toolbar;

Information obtained from this calculation:

-

Figure 3 shows the calculated evolution of particle number density with experimental data, time is in second. It is seen that the particle number density increases quickly within the first hour and then decreases slightly during ageing at 185 °C. It decreases drastically when heating up to 350 °C;

-

Figure 4 shows the calculated evolution of particle size with experimental data. It is seen that the particle size increases gradually during ageing at 185 °C. It increases drastically when heating up to 350 °C;

-

Figure 5 shows the calculated evolution of hardness with experimental data. It is seen that the hardness increases gradually during ageing at 185 °C. It drops quickly when heating up to 350 °C.