Carburization with Input Flux

Purpose: Learn to perform diffusion simulation at constant temperature for a carburization process with an input flux as boundary condition.

Module: PanDiffusion

Thermodynamic and Mobility Database: Fe-Si-C.tdb

Batch file: Example_#4.7.pbfx

Calculation Procedures:

-

Create a workspace and select the PanDiffusion module following Pandat User's Guide: Workspace;

-

Load Fe-Si-C.tdb following the procedure in Pandat User's Guide: Load Database , and select all three components;

-

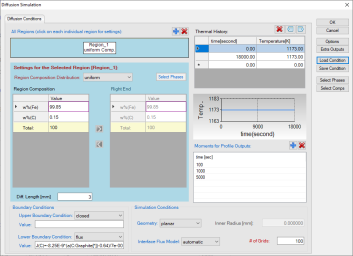

Click on the menu "PanDiffusion → Diffusion Simulation" and set up the calculation condition as shown in Figure 1. First click the red “X” above Regions to delete Region_2 and leave one Region only;

-

Click on Region_1 and set the composition as 0.15C-99.85Fe (wt%), the Diff. Length as 3 mm, and the # of Grids as 200;

-

The Thermal History is at 1173 K for 18000 seconds;

-

Click on Lower Boundary Condition (left edge of Region_1) and select “flux”, and set the Value as “J(C)=-8.25E-9*(a(C:Graphite[*])-0.64)/7e-006”;

-

In the settings shown in Figure 1, composition profiles at the initial and final stages, as well as at 100s, 1000s and 5000s, will be outputted. Click OK to perform calculations.

Post Calculation Operation:

-

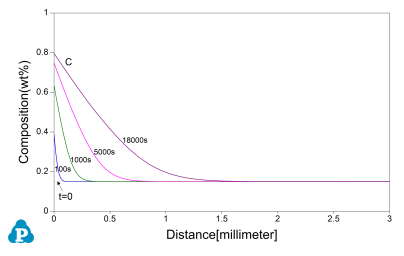

Enlarge the composition range between 0 and 1 (wt%) to clearly display Carbon composition. The calculated plot is show in Figure 2Change graph appearance and add text following the procedure in Pandat User's Guide: Property.

Information obtained from this calculation:

-

Carbonization process in Fcc of the Fe-C system. Lower boundary condition is an input flux. This setting provides user an option when the flux of C is known in the environment;

-

After holding the material at 1173K for 18000 seconds, composition profiles can be viewed at selected stages. The carbon composition gradually diffused from the boundary to the body;