Dynamic Recrystallization Simulation of Ni-14at.%Al Alloy

In this tutorial, the Ni -14 at% Al alloy is also used for dynamic recrystallization simulation in PanEvolution. The related batch file (Ni-14Al_RX_JMAK.pbfx), thermodynamic and mobility database ( AlNi_Prep.tdb ) , kinetic parameters database (Ni-14Al_RX_JMAK.kdb) and the initial condition file (Al-Ni.ini) can be found in the Pandat™ installation folder "\Pandat 2024 Examples\PanEvolution\Grain_Recrystallization\JMAK":

Step 1: Create a Workspace

The same procedure as described in the previous tutorial Section Step 1: Create a Workspace

Step 2: Load Thermodynamic and Mobility Database

The same procedure as described in the previous tutorial Section Step 2: Load Thermodynamic and Mobility Database

Step 3: Load Kinetic Parameters Database (kdb file)

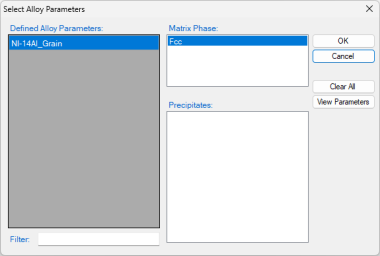

The procedure is similar to the description in the previous tutorial Section Step 3: Load Kinetic Parameters Database (KDB file). The "Defined Alloy parameters" in this kdb file is "Ni-14Al_Grain", as shown in Figure 1.

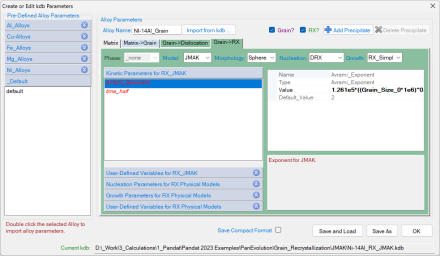

Click the “View Parameters”, the “Create or Edit kdb Parameters” dialog pops out as shown in Figure 2. The parameters in this kdb file contains not only the "matrix" , but also some other items "Matrix->Grain" to define the properties of the original grains, "Grain->Dislocation" to define the dislocation density related properties, "Grain->RX" to define the parameters related to the recrystallization grains. The meaning of the parameters are detailed shown in Section PanEvolution tables.

Step 4: Grain Growth and Recrystallization simulation

After successfully loading the thermodynamic and mobility database (TDB and PDB file) and the kinetic parameters database (KDB file), which contains kinetic parameters for the matrix grains, dislocation density and recrystallization grains, the function for grain growth and Recrystallization simulation is then being activated.

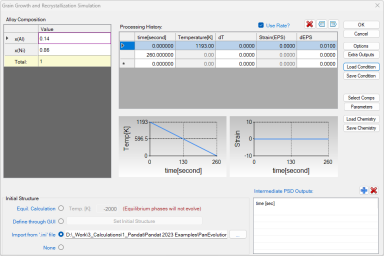

To perform a grain growth and recrystallization simulation, choose from Pandat™ menu “PanEvolution/PanPrecipitation → Grain Growth/Recrystallization”, or click icon ![]() from the toolbar. A dialog box entitled “Grain Growth and Recrystallization Simulation”, as shown in , pops out for user’s inputs to set up the simulation conditions: alloy composition, processing history and initial structure.

from the toolbar. A dialog box entitled “Grain Growth and Recrystallization Simulation”, as shown in , pops out for user’s inputs to set up the simulation conditions: alloy composition, processing history and initial structure.

-

Alloy Composition: User can set alloy composition by typing in or use the Load Chemistry function.

-

Processing History: Select the "Use Rate?" to define the conditions as Rate. This condition shown in Figure 3 is at 1193 K with strain rate of 0.01 s-1 for 260 seconds.

-

Set initial Structure: Users can set initial structure through the function “import from ‘.ini’ file” or “Define through GUI”. In this example, the "Al-Ni.ini" file is imported as the initial structure.

Step 5: Customize Simulation Results

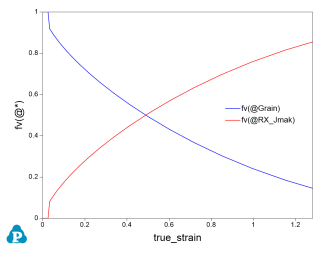

The same as all other calculations available in Pandat™, upon the completion of the recrystallization simulation, a default table with related kinetic properties, such as time, strain and true strain, volume fraction grain and recrystallization grains, grain size, dislocation density and yield strength (sigma_y), is automatically generated. Two default graphs for the volume fraction of the grain and recrystallization grains, and the yield strength vs true strain are plotted as show in Figure 4.

Based on the data in the default table, users can also plot other properties, for example, the recrystallizated grain size and the average grain size as shown in Figure 5.