Material-to-Material Calculation

The Material-to-Material function is designed to perform calculations from one Material to another Material, which allows users to understand the phase equilibrium and phase transformation between two multi-component Materials. This functionality will derive many applications.

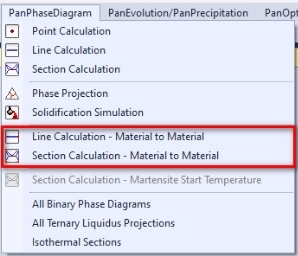

Under the PanPhaseDiagram menu, as shown in Figure 1, two new functions have been added

• "Line Calculation – Material to Material"

• "Section Calculation – Material to Material"

Line Calculation – Material to Material

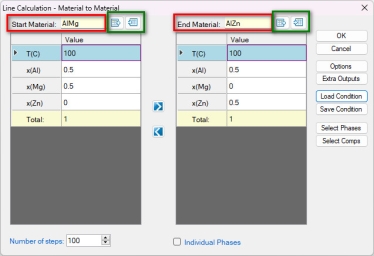

Figure 2 shows the condition setting interface for the "Line Calculation – Material to Material" function. Contrast to a standard line calculation, this interface includes two additional fields: "Start Material" and "End Material", which are marked with red frames in Figure 2. These fields define the names of the materials.

Note: The material names must not contain spaces. If a material name is identical to an element name, Pandat will automatically add the prefix "M_" to distinguish it from a chemical element.

|

(a) |

(b) |

|

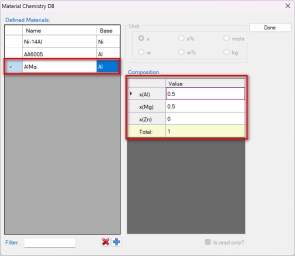

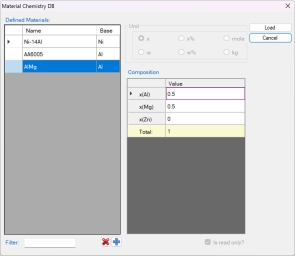

Figure 3: Material Chemistry Database (DB): (a) Save material composition into Material Chemistry DB; (b) load material composition from Material Chemistry DB |

|

Material compositions can be entered manually or imported from the Materials Chemistry Database (DB) using the green-framed icon ![]() in Figure 2. The left icon

in Figure 2. The left icon ![]() allows users to save custom compositions and material names into the DB with the current unit settings (Figure 3a) . The right icon

allows users to save custom compositions and material names into the DB with the current unit settings (Figure 3a) . The right icon ![]() enables users to load material compositions from the DB (Figure 3b) : select a material and click "Load." If unit settings differ from those saved, Pandat will automatically convert the composition to match the current units.

enables users to load material compositions from the DB (Figure 3b) : select a material and click "Load." If unit settings differ from those saved, Pandat will automatically convert the composition to match the current units.

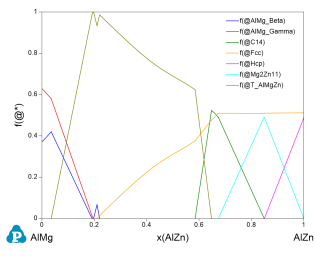

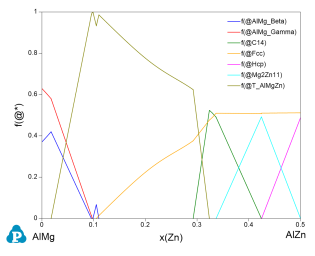

Set material names and compositions, then click “OK” to run the calculation (Figure 2). By default, the graph plots phase fractions against the Material AlZn content (Figure 4a). Unlike a standard line calculation, where the X-axis represents an elemental composition (at a fixed temperature), the default X-axis is the amount of the second Material for Material-to-Material Line Calculation (Figure 4a). Moreover, the elemental composition data is also stored in the output table, which allows users to plot a diagram using elemental axes if needed (Figure 4b).

|

(a) |

(b) |

|

Figure 4: Line Calculation – Material to Material: (a) Default plot with Material composition as X-axis; (b) Element composition as X-axis. |

|

Section Calculation – Material to Material

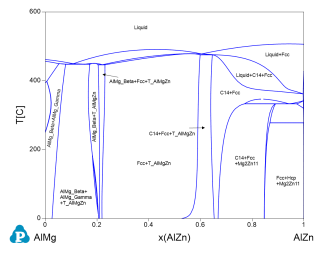

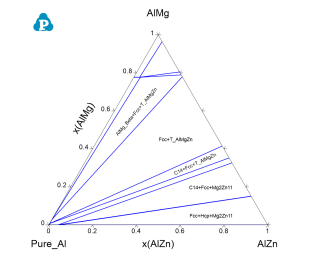

The Section Calculation – Material to Material function includes two types: Vertical Section and Isothermal Section.

Figure 5 illustrates the condition-setting interfaces for these two types of calculations:

Vertical Section (Figure 5a): The X-axis represents the compositions of the two Materials, while the Y-axis represents the temperature (T).

Isothermal Section (Figure 5b): A phase diagram at a constant temperature, where three different Materials define the three points in the composition space.

The calculated phase diagrams for these settings are shown in Figure 6.