Solutions for Permanent Magnetic Materials

The Fe-Nd-B sintered magnet is a very important material to achieve high efficiency in electric-mechanical energy conversion devices such as main motors in electric vehicles and generators of wind-power turbines. The magnetic properties of Fe-Nd-B based magnets are determined by both the intrinsic physical properties (HA, Ms, Tc) of the existing phases and the extrinsic properties, such as Hci, intergrain precipitates and porosity. Knowledges on phase relationships and microstructure development during the sintering process are crucial for the development of Fe-Nd-B sintered magnets with desired properties. Using Pandat software with the PanMag database, one can predict not only the phase equilibria and solidification paths of the magnets, but also many magnetic properties, such as Curie temperature, saturation magnetization (Bs) and magnetocrystalline anisotropy field (HA) of the magnetic materials. Here are a few application examples, more examples are collected in the PanMag database manual.

Application Examples

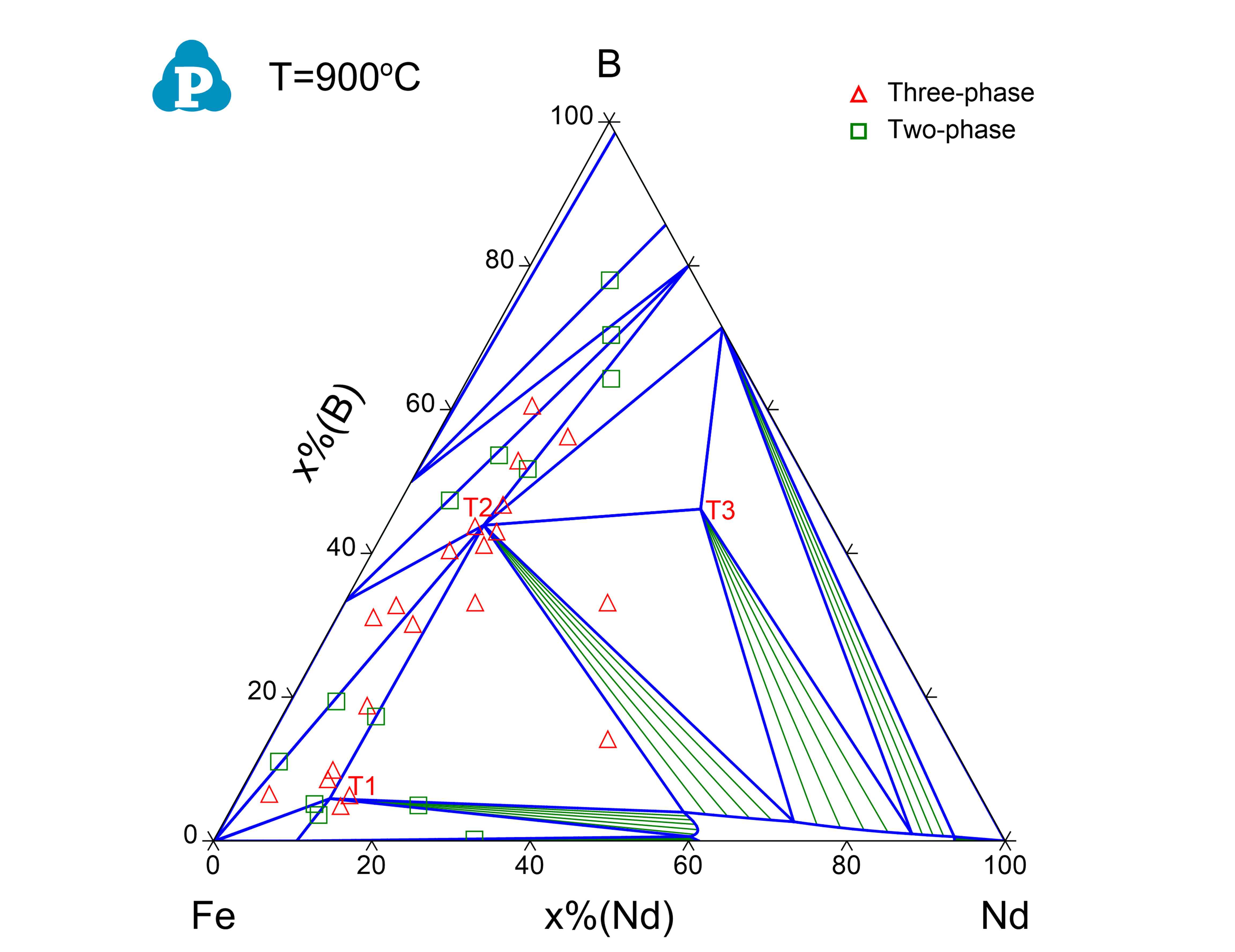

Phase Diagram of magnetic alloy systems

Typical phase diagrams can be calculated using Pandat software and PanMag database. Here shows the isothermal section of Fe-Nb-B at 900 °C. The calculated phase stabilities are in good agreement with the experimental data.

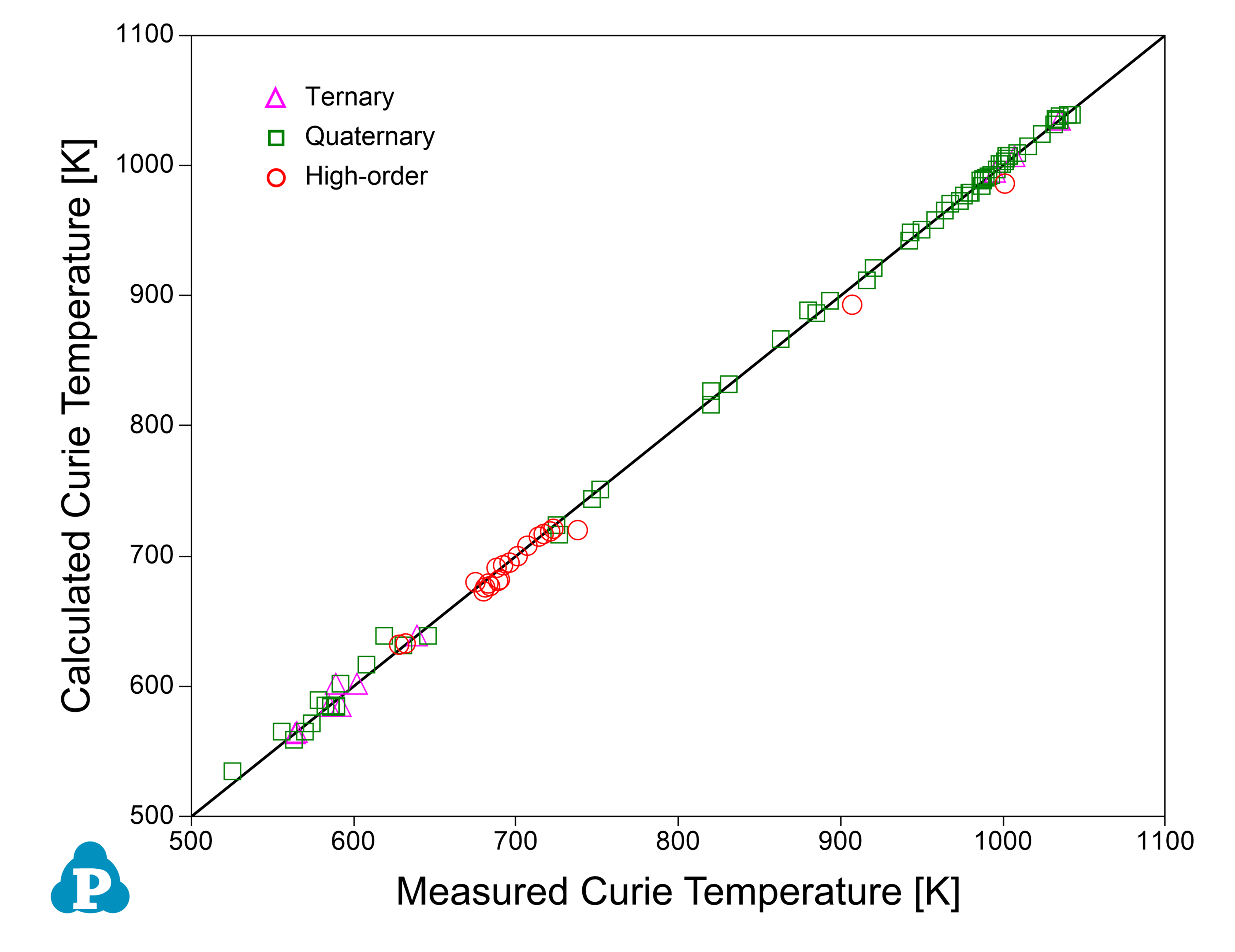

Magnetic properties of the T1 phase

By selective alloying additions, the intrinsic properties, such as the magnetocrystalline anisotropy field (HA) and the Curie temperature (TC), and the extrinsic properties (mainly Hci) of the T1 phase can be successfully improved. The effect of alloying elements on these properties can be predicted in Pandat. The left figure shows the excellent agreement of calculated and measured Curie temperatures for a series of T1 phase.

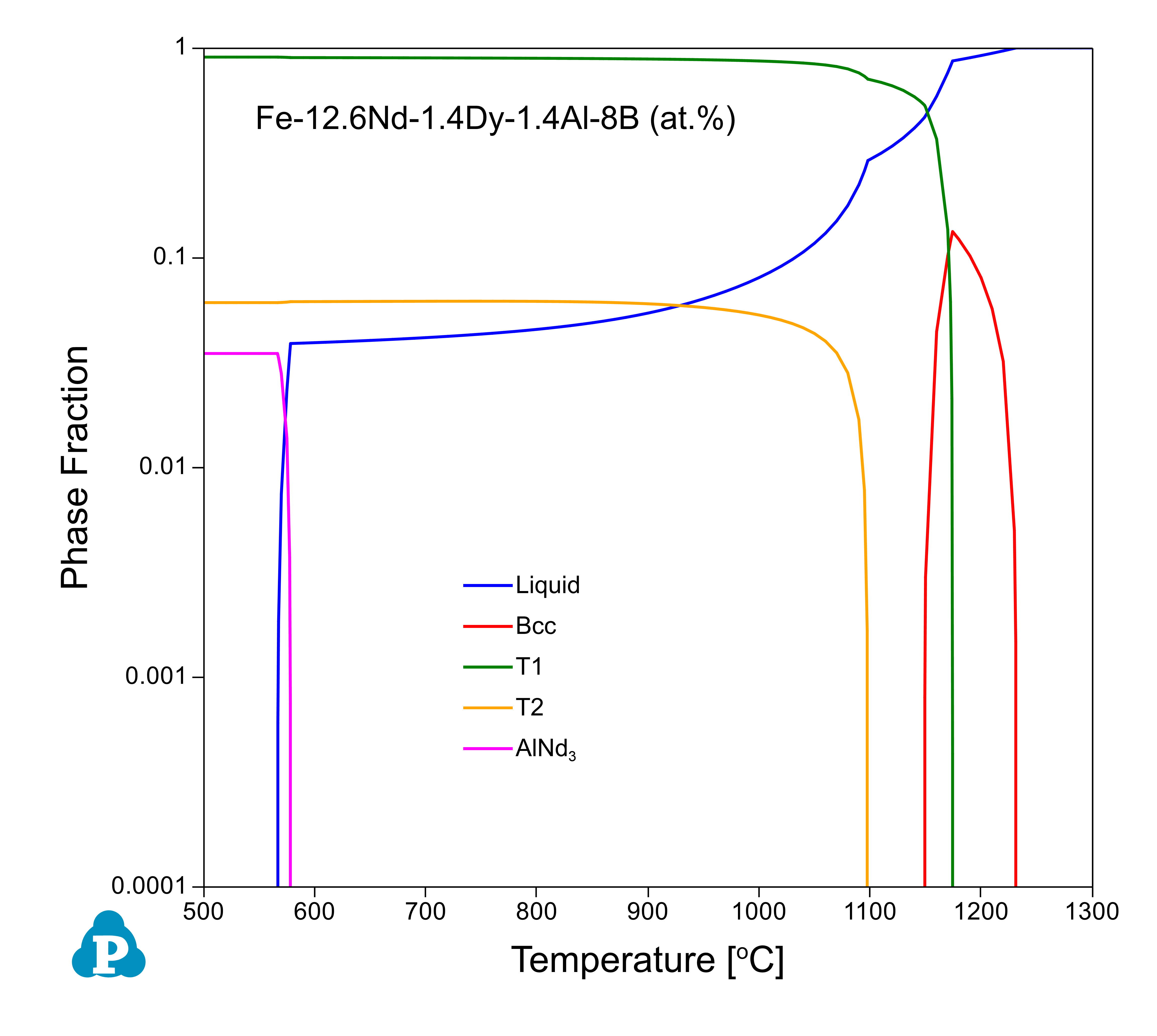

Solidification of the Fe-Nd-B alloys

The replacement of a small amount of Fe with Al may increase the coercivity of the RE2Fe14B phase by up to 50%. Substitution of Fe with Al increases the c/a ratio of the T1 phase, which is believed to weaken the exchange interaction between Fe atoms along the c direction and result in the decrease of domain wall thickness. The right figure shows the phases formed during solidification and the fraction of each phase for alloy Fe-12.6Nd-1.4Dy-1.4Al-8B (at.%) under Lever rule condition.

Still have question? Contact us to find a solution for your applications.