PanPhaseField

The PanPhaseField is designed to simulate microstructure evolution and seamlessly integrated with the user-friendly Pandat Graphical User Interface (PanGUI) as well as the thermodynamic calculation engine, PanEngine through an innovative data management system, PanDataNet. PanEngine provides PanPhaseField with reliable thermodynamic data, such as chemical potential, phase equilibrium and mobility of multi-component system. PanDataNet provides data management support which makes phase field simulation of multi-component commercial alloys feasible.

PanPhaseField provides two built-in applications of precipitation and spinodal decomposition. It is also a framework allowing users to implement their own phase-field models. With the PanPhaseField SDK, researchers can develop their own phase-field application plugins. Plugins can directly get the needed thermodynamic input from CALPHAD database and use Pandat GUI to visualize their simulation results.

PanPhaseField

- direct coupling with CALPHAD

- feasible for multi-component alloys

- open architecture for user’s model plugin

Some Key Features of PanPhaseField Module

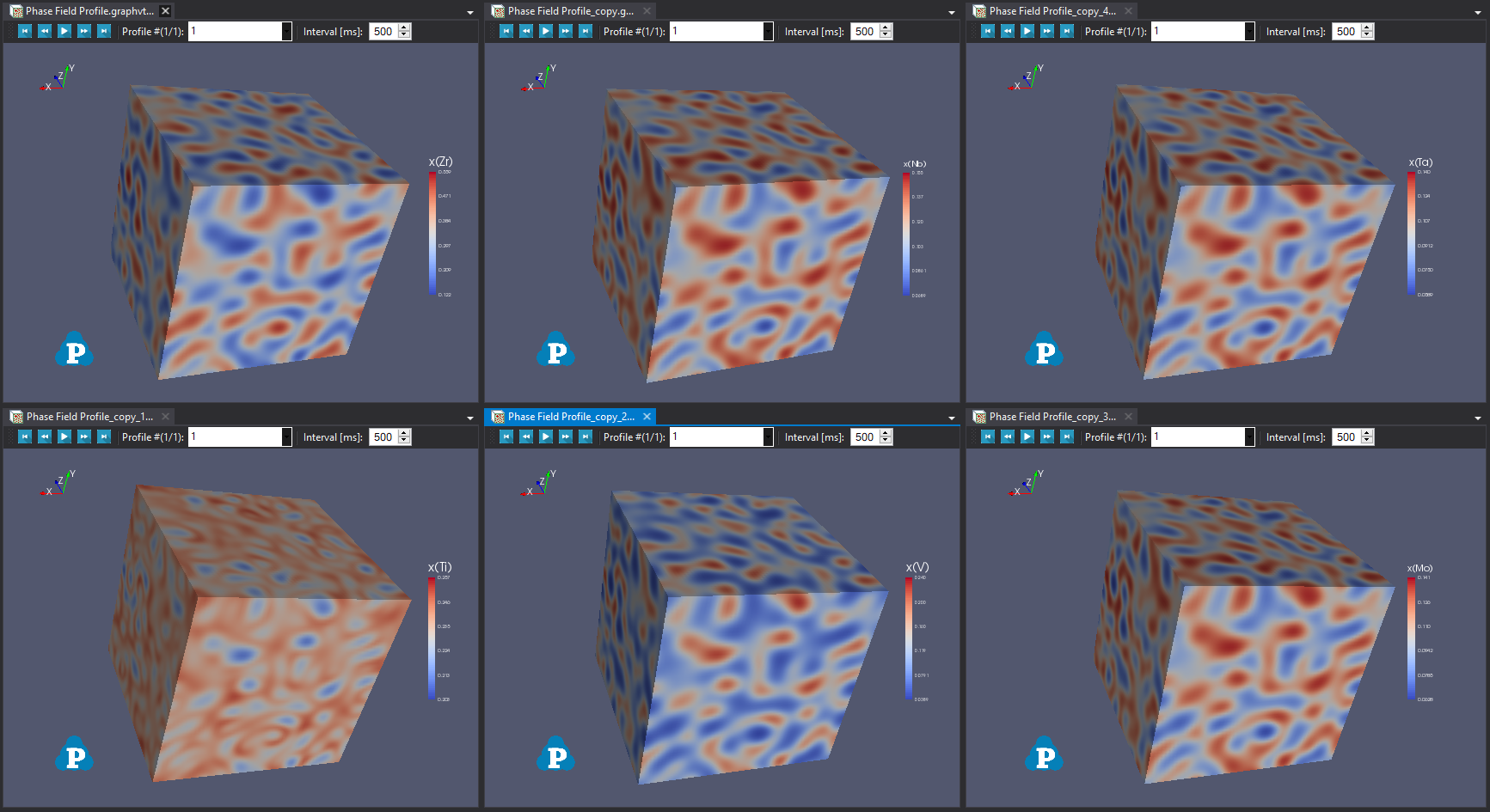

Simulated spinodal decomposition of a refractory HEA (Zr-10.5Mo-11.6Nb-10.2Ta-23.6Ti-11.8V in at. %) for one hour.

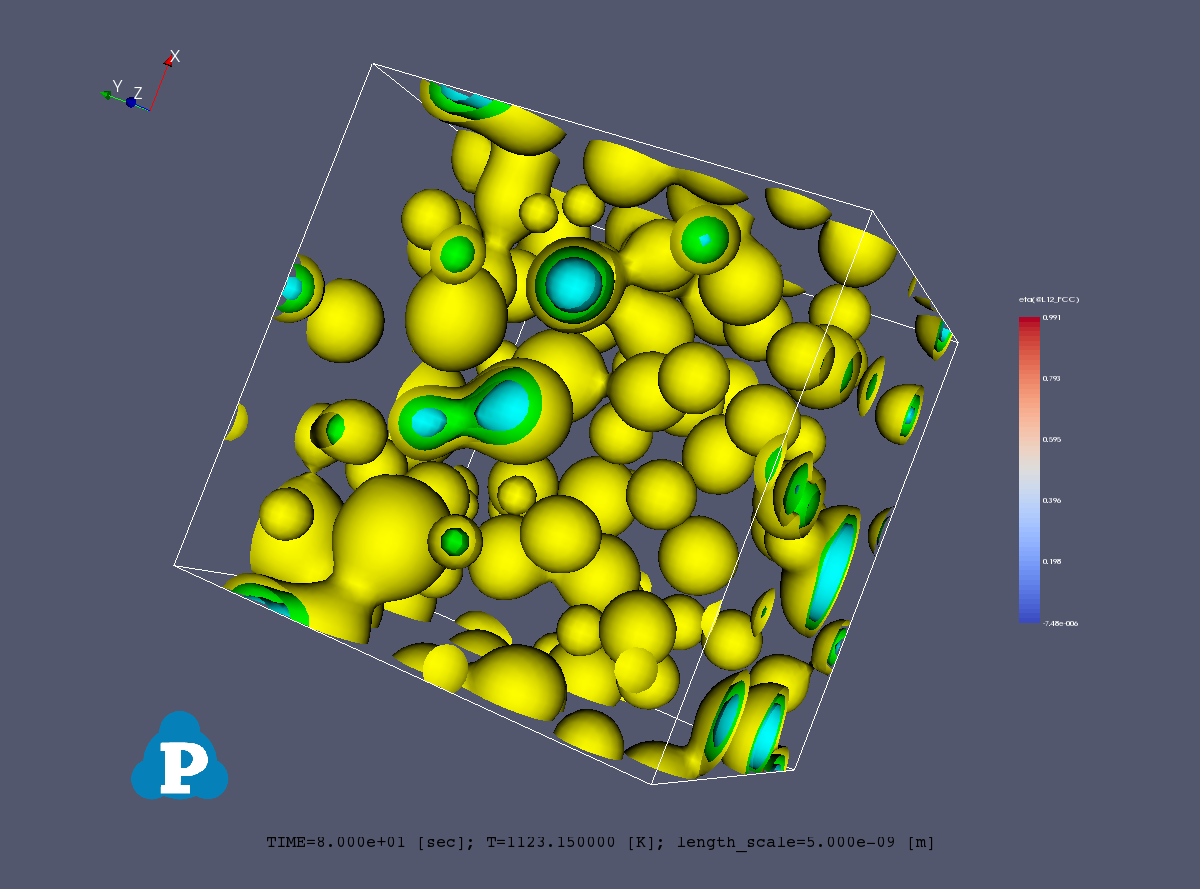

Simulated γ/γ’ microstructure for the Ni-15at%Al binary alloy during two-step heat treatment process at time=240s.

- Revolutionary technology: PanPhaseField enables a direct coupling between phase-field models and CALPHAD method in a fast and efficient way. No curve fitting of Gibbs energy is needed and no assumption of pseudo–binary or –ternary is necessary. Phase-field simulation of multi-component commercial alloys becomes a reality!

- The state of art software design: The three-layered architecture and Object-Oriented (OO) software design make PanPhaseField highly flexible and easy to extend. Good scalability: from 1D to 3D, and from small system to big system.

- Refined phase field models: Two built-in models are implemented for precipitation and spinodal decomposition simulation of multi-component alloys. More phase field models will be developed in the future releases.

- Open architecture: PanPhaseField adopts an open architecture which allows users to plug in their own phase-field models for broader applications.

- User-friendly GUI: Convenient inputs and powerful 1D/2D/3D visualization based on the VTK engine are provided. The simulation results in VTK files are also compatible with ParaView. Model parameters are stored in the phase-field database file (.pfdb), which allows user to manage these parameters easily.

- Cross platform and high performance: PanPhaseField can run in different computing environments: Windows/Linux PC, Clusters and Cloud machines with high performance multi-thread algorithms.