Two-step aging of a binary Ni-Al alloy

- Purpose: Learn to perform phase-field simulation of precipitation in a Ni-Al binary alloy under specified thermal conditions using PanPhaseField Module. Learn to use the features in PanPhaseField Module.

- Module: PanPhaseField

- Database: AlNi_Prep.tdb and AlNi.pfdb

Calculation Method 1

- Create a workspace and select the PanPhaseField module following Pandat User’s Guide 2.1;

- From menu bar click Batch Calc-> Batch Run, or click icon , then select Example_#6.1.pbfx;

Calculation Method 2:

- Create a workspace and select the PanPhaseField module following Pandat User’s Guide 2.1;

- Load TDB file AlNi_Prep.tdb through menu Database->Load TDB or PDB or by click icon

, and select the elements: Al, Ni.

, and select the elements: Al, Ni. - Load PFDB file AlNi.pfdb through menu PanPhaseField->Load PFDB or by click icon

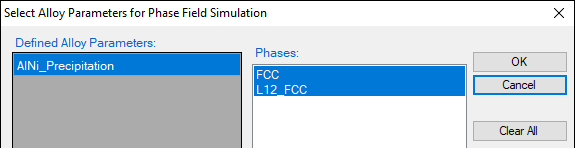

, select the available alloys: Mg alloys, as shown in Figure 1.

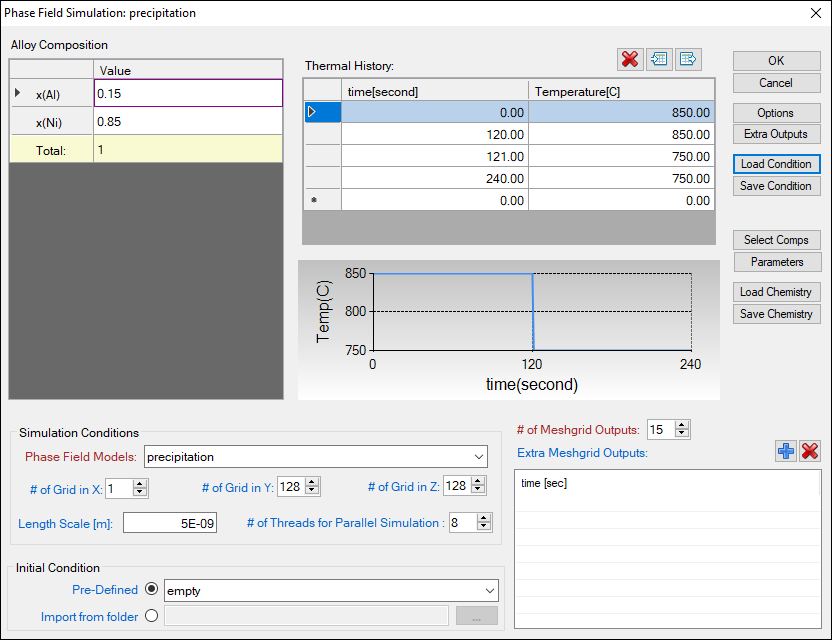

, select the available alloys: Mg alloys, as shown in Figure 1. - Set phase-field precipitation simulation conditions as shown in Figure 2. The alloy composition is Ni-15x.% Al. The first thermal stage is 850°C for 120 seconds. Then the temperature is reduced to 750 °C in 1 second. The second thermal stage is 750°C for another 120 seconds. Please pay attention to the units of the time and temperature when set conditions.

- This 2D simulation uses a mesh grid of 128*128, and a length scale of 5E-9 m is applied. Please pay attention to the units of length when set conditions.

- 15 profiles of mesh grid will be outputted during the simulation.

- Set number of threads to 8. If your computer has less than 8 threads, Pandat will automatically apply the max available threads on your computer.

Figure 1. Loading the AlNi.pfdb file

Figure 2. Set phase-field precipitation simulation conditions

Post Calculation Operation:

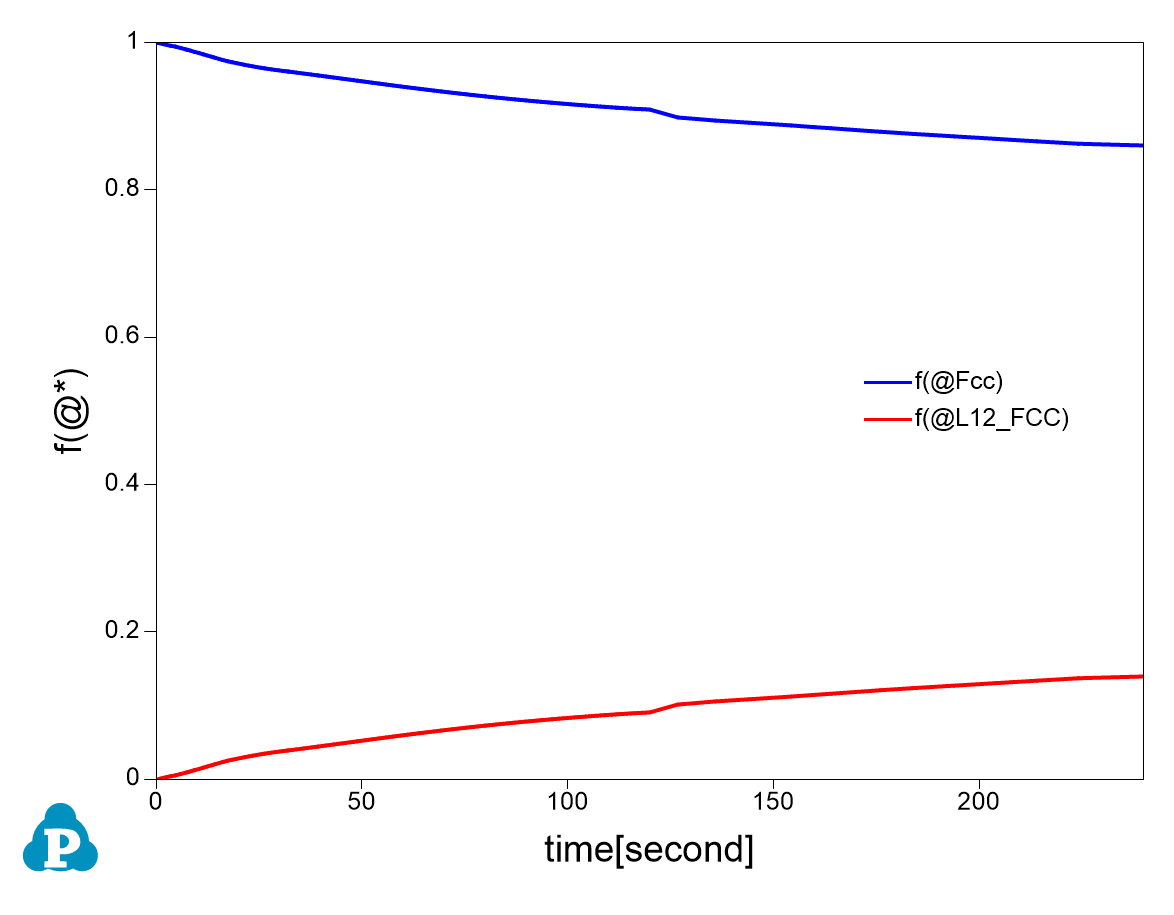

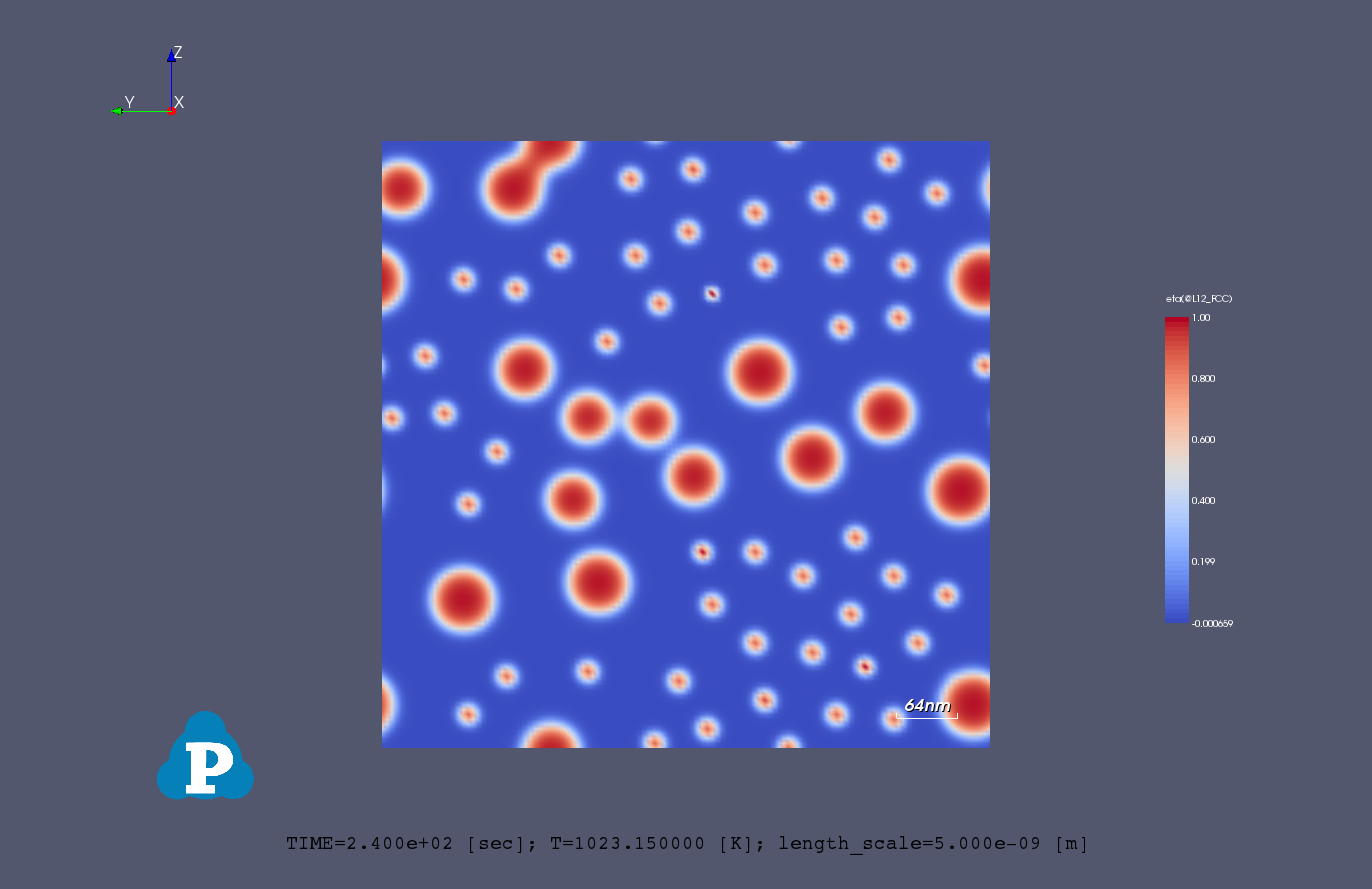

- The default plot presents the time-evolution of phase volume fraction as shown in Figure 3, and the last frame of microstructure as shown in Figure 4.

- Change graph appearance following the procedure in Pandat User’s Guide 2.3.1;

- Add legend following the procedure in Pandat User’s Guide 2.3.3;

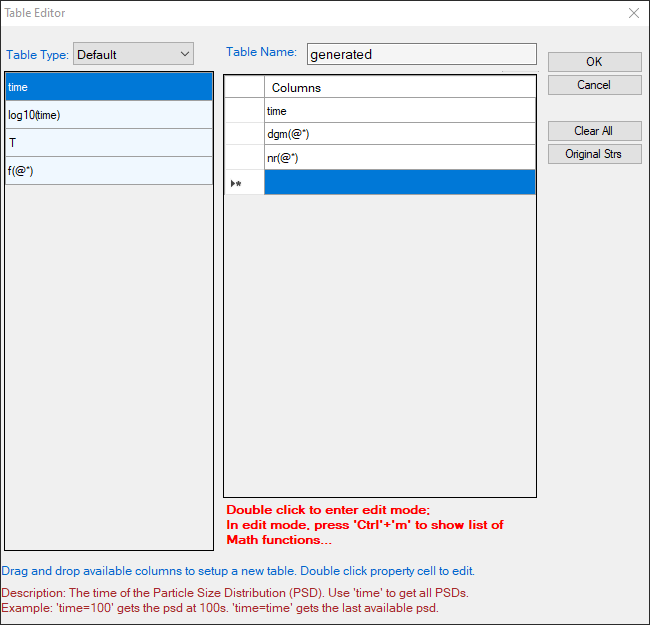

- Add a new table as shown in Figure 5 with the Table Type as Default. Add columns of “time”, “dgm(@*)” as driving force of phases and “nr(@*)” as nucleation rate of phases.

Figure 3. Default plot showing time-evolution of phase volume fraction

Figure 4. Default plot showing the last frame of L12 particle microstructure

Figure 4. Create a new table with driving force and nucleation of phases

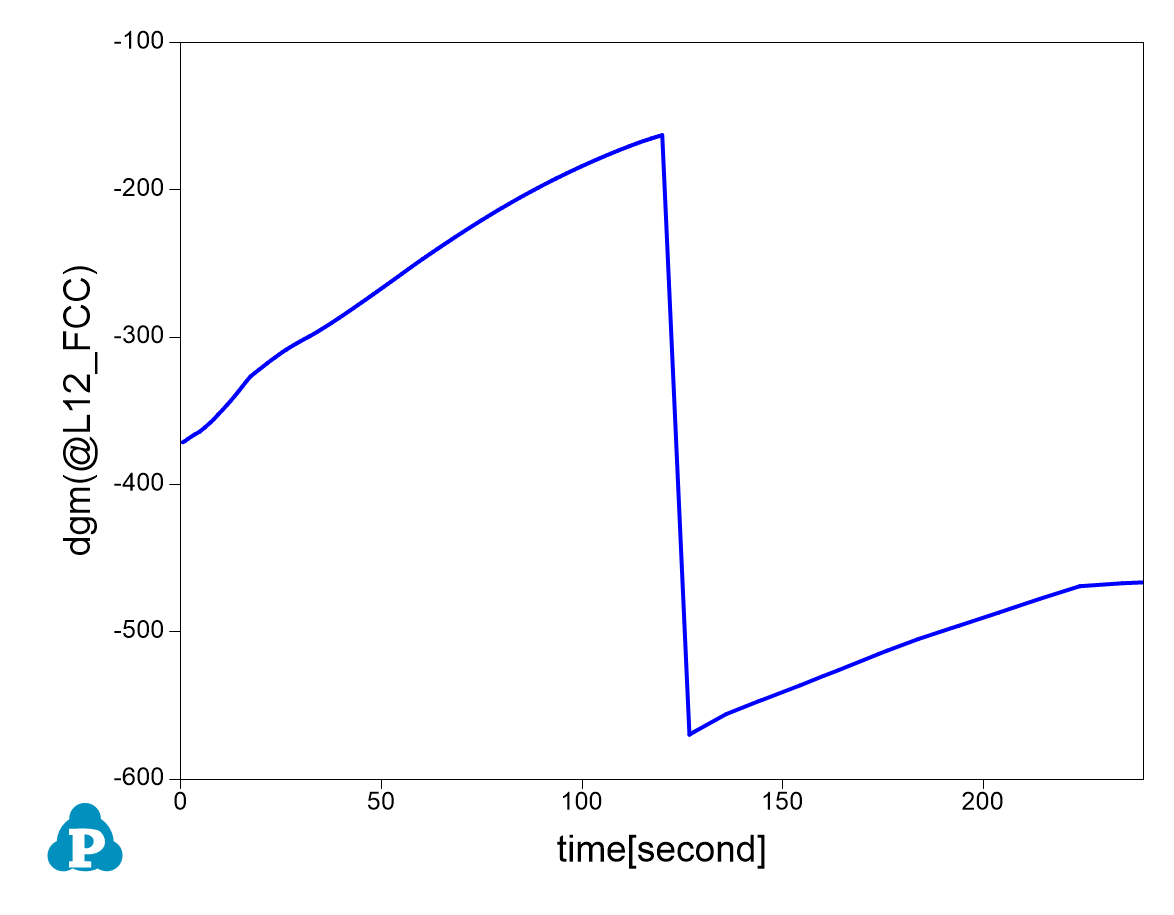

- Plot driving force of L12 phase from the new table by selecting the time as x-axis and driving force dgm(@L12_FCC) as y-axis. The plot is shown in Figure 6.

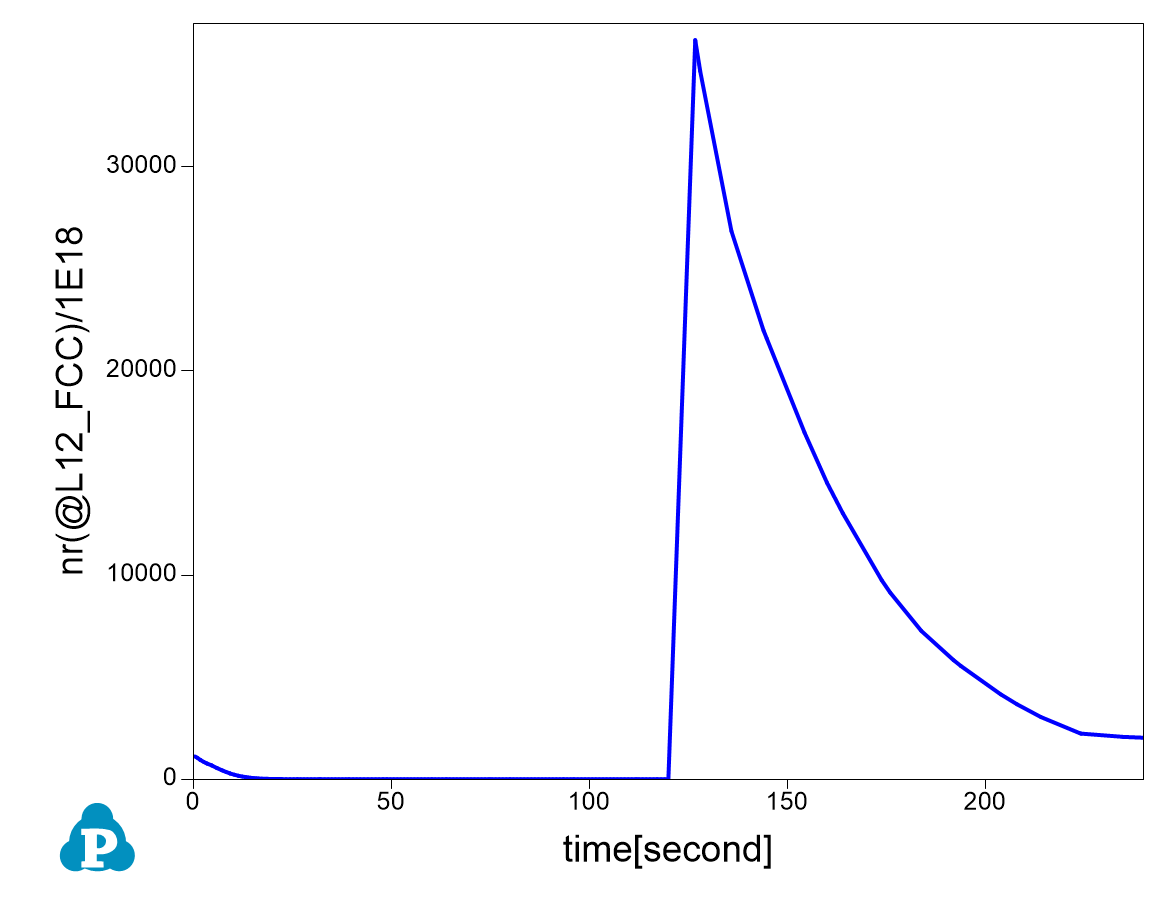

- Plot nucleation rate of L12 phase from the new table by selecting the time as x-axis and nucleation rate nr(@L12_FCC) as y-axis. The plot is shown in Figure 7.

Figure 6. Time-evolution of driving force of L12 phase

Figure 7. Time-evolution of nucleation rate of L12 phase