PanTiAl

Thermodynamic Database for TiAl-Based Alloys

- Thermodynamic

- Mobility

- Thermophysical Property: Molar Volume; Surface Tension; Viscosity

PanTiAl

PanTiAl Quick Overview

-

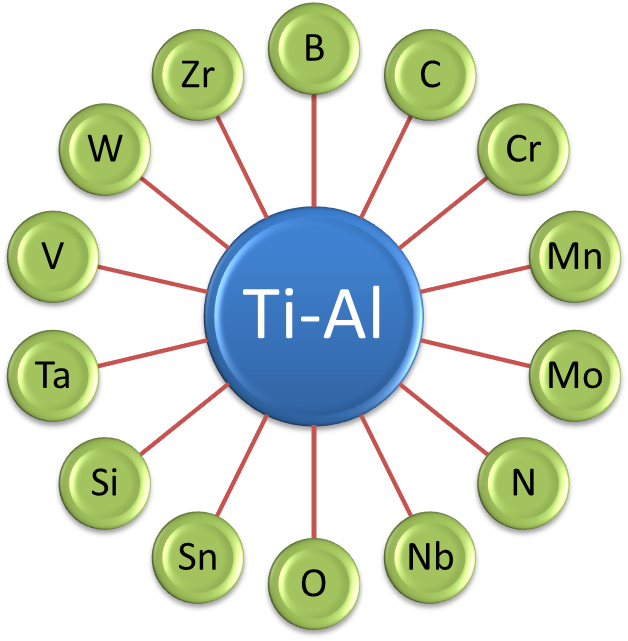

Number of components: 16

-

Number of phases: 208

-

Major alloying elements: Al, Cr, Mo, Nb, Ta, Ti, V, W and Zr

-

Minor alloying elements: B, C, Mn, N, O, Si and Sn

PanTiAl – Thermodynamic database (TH), Mobility database (MB), and Thermophysical property (TP) database for multi-component TiAl-based alloys.

- The PanTiAl_TH thermodynamic database consists of 16 components, 208 phases and 117 fully assessed binary and ternary systems. The database is validated by TiAl-based alloys.

- The PanTiAl_MB mobility database includes assessed mobility model parameters for the Liquid, Bcc, Fcc, and Hcp solution phases. It is compatible with the PanTiAl_TH and suitable for the simulation of diffusion controlled phenomena of multi-component TiAl-based alloys.

- The PanTiAl_TP thermophysical property database includes the molar volume database covers all the 208 phases assessed in the PanTiAl_TH, the surface tension and viscosity properties for the liquid phase. It can be combined with the thermodynamic database for the simulation of thermo-physical properties of TiAl-based alloys, such as density, thermal expansion, and solidification shrinkage.

Applications

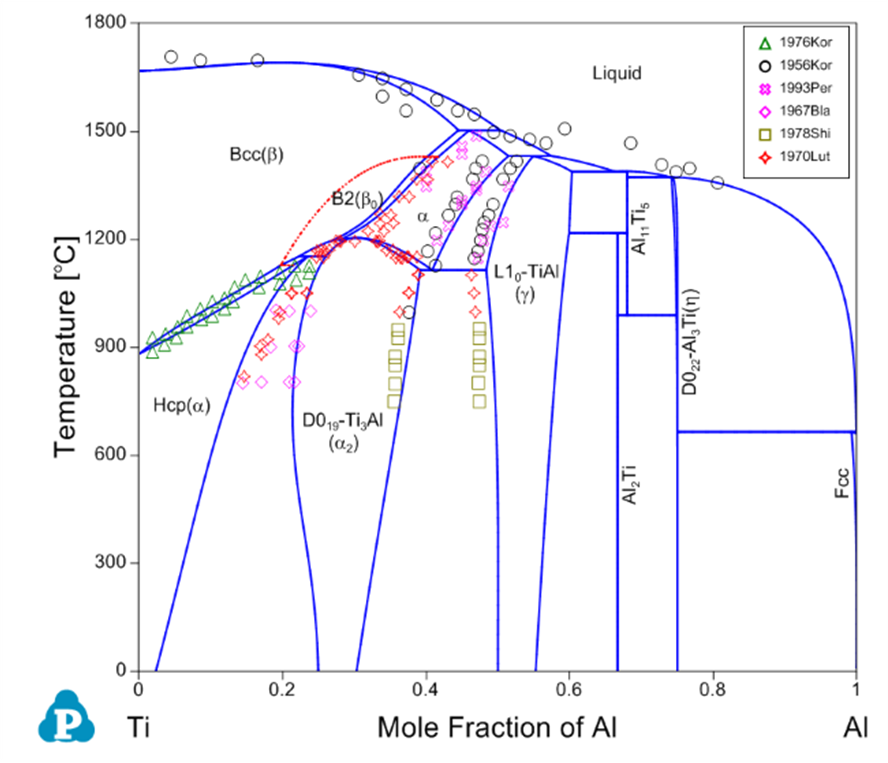

Calculated Ti-Al binary phase diagram

PanTiAl database focuses in the composition region with as high as 50at% of Al, thermodynamic description for the Ti-Al binary, as well as Ti-Al-X (X represents Cr, Mn, Mo, Si, V, W) ternaries are critically important. An example shows the calculated Ti-Al binary phase diagram.

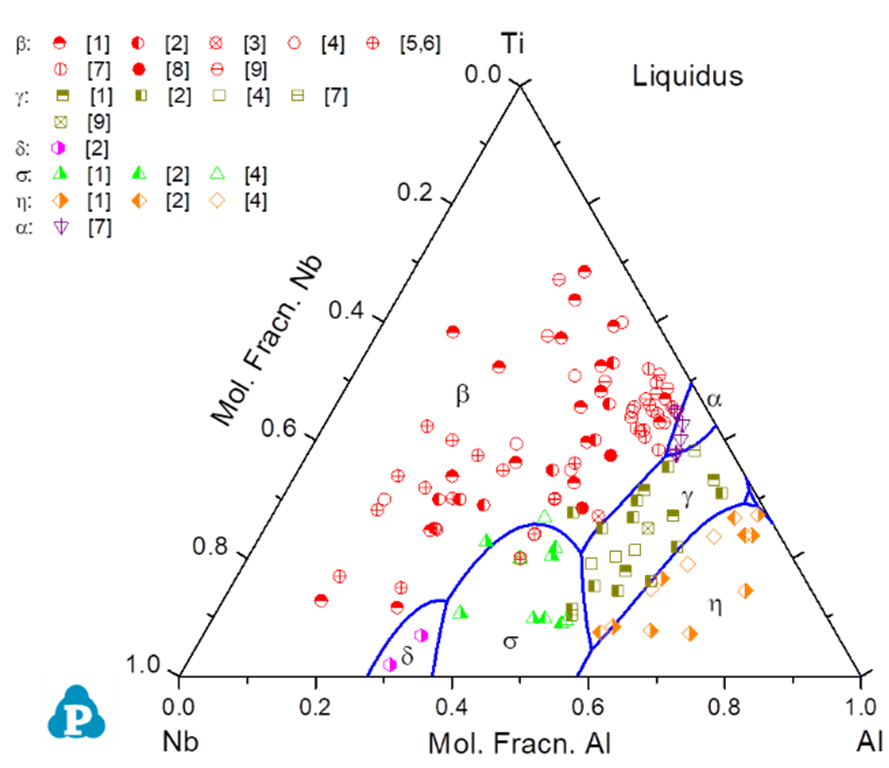

Calculated liquidus projection of the Ti-Al-Nb system with experimentally determined primary solidified phase

The calculated liquidus projection of the Ti-Al-Nb system in which the symbols indicating the experimentally determined primary solidified phases.

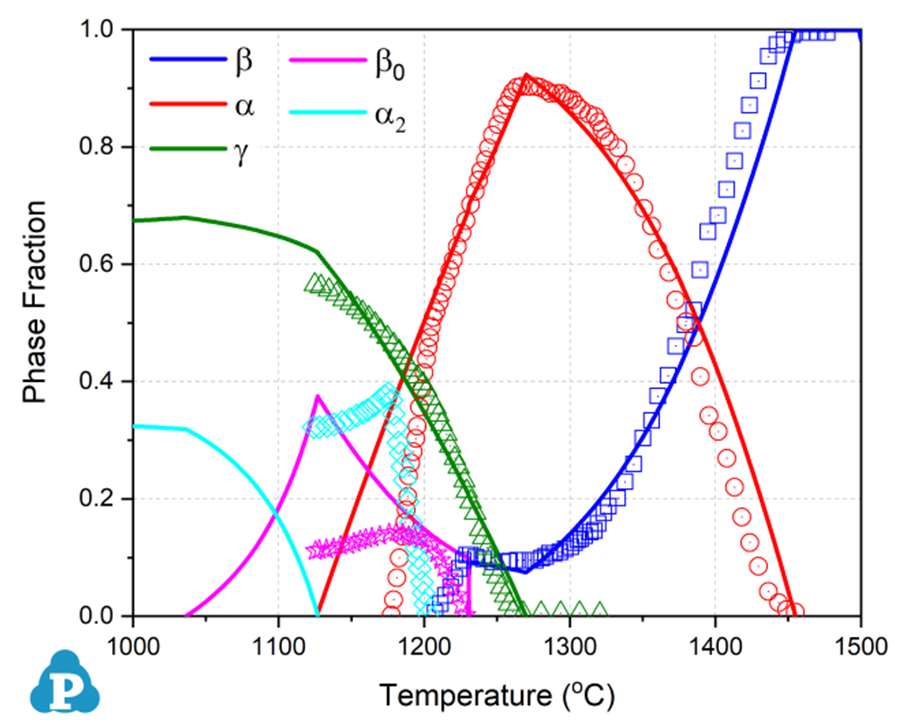

Comparison of calculated and measured phase fractions vs. temperature for TNM alloy

A comparison of the calculated and measured phase fraction as a function of temperature for TiAl-based TNM alloy.

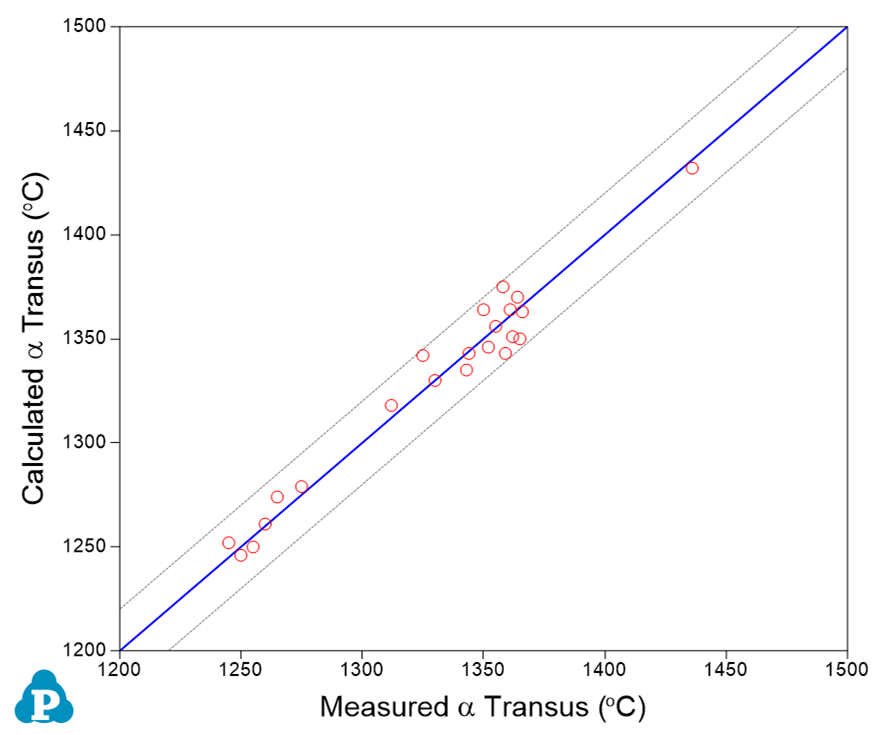

Comparison of calculated and measured a-transus temperature for 22 TiAl-based alloys

This example compares the calculated and measured a-transus temperature for 22 TiAl-based alloys.

PanTiAl_TH can be integrated with PanTiAl_MB and PanTiAl_MV to simulate diffusion controlled phenomena and thermo-physical properties of multi-component TiAl-based alloys.