PanTitanium

Thermodynamic Database for Titanium-Based Alloys

- Thermodynamic

- Mobility

- Thermophysical Property: Molar Volume; Surface Tension; Viscosity

PanTitanium

PanTitanium Quick Overview

-

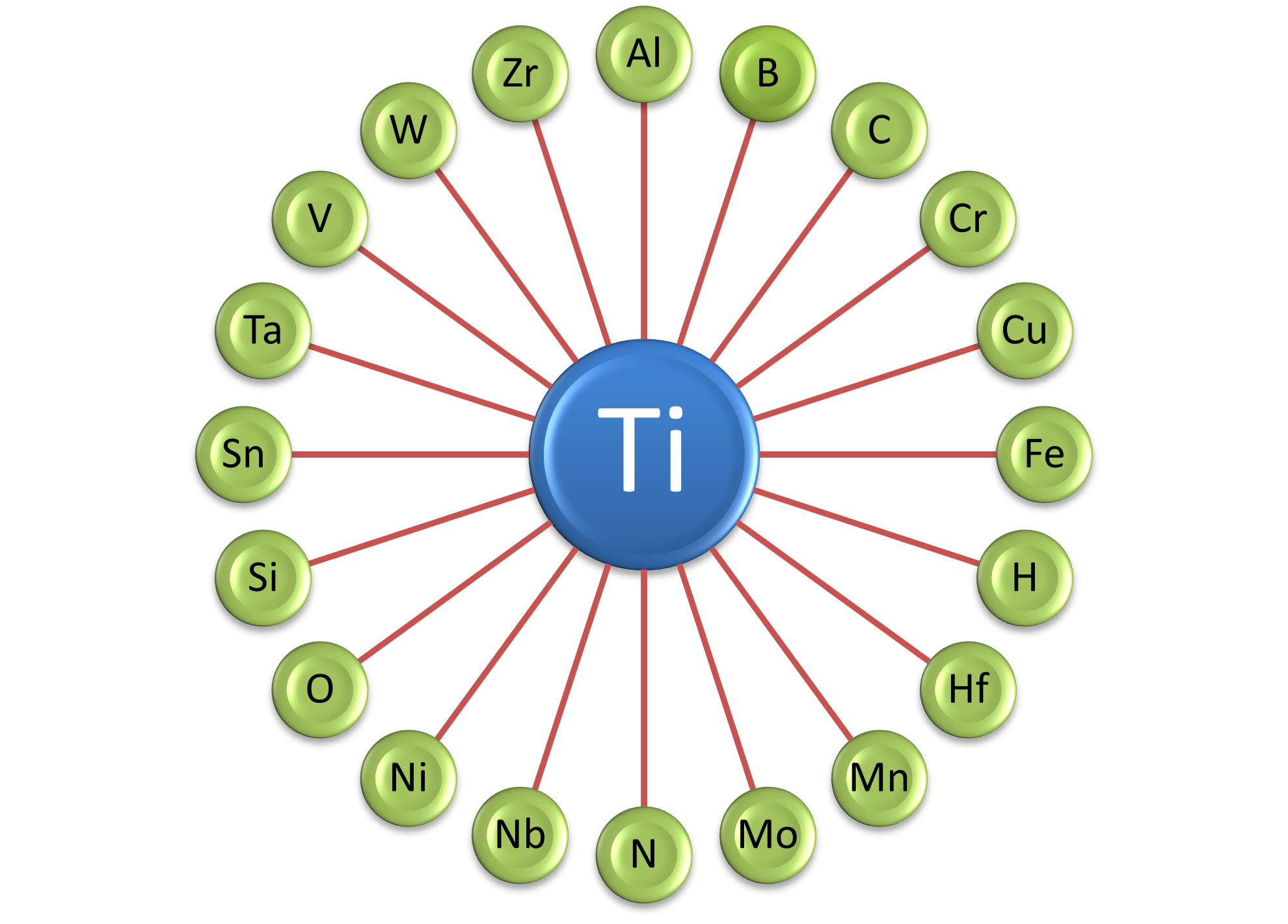

Number of components: 21

-

Number of phases: 340

-

Major alloying elements: Al, Cr, Cu, Fe, Mo, Nb, Ni, Sn, Ta, Ti, V, W and Zr

-

Minor alloying elements: B, C, H, Hf, Mn, N, O and Si

PanTitanium – Thermodynamic database (TH), Mobility database (MB), and Thermophysical property (TP) database for multi-component titanium alloys.

- The PanTi_TH thermodynamic database consists of 21 components, 340 phases and 178 fully assessed binary and ternary systems. The database is validated by many Ti-based alloys.

- The PanTi_MB mobility database includes assessed mobility model parameters for the Liquid, Bcc, Fcc, and Hcp solution phases. It is compatible with PanTi_TH and suitable for the simulation of diffusion controlled phenomena of multi-component titanium alloys.

- The PanTi_TP thermophysical property database includes the molar volume database covers all the 340 phases assessed in the PanTi_TH, the surface tension and viscosity properties for the liquid phase. It can be combined with the thermodynamic database for the simulation of thermo-physical properties of Ti-based alloys, such as density, thermal expansion, and solidification shrinkage.

Applications

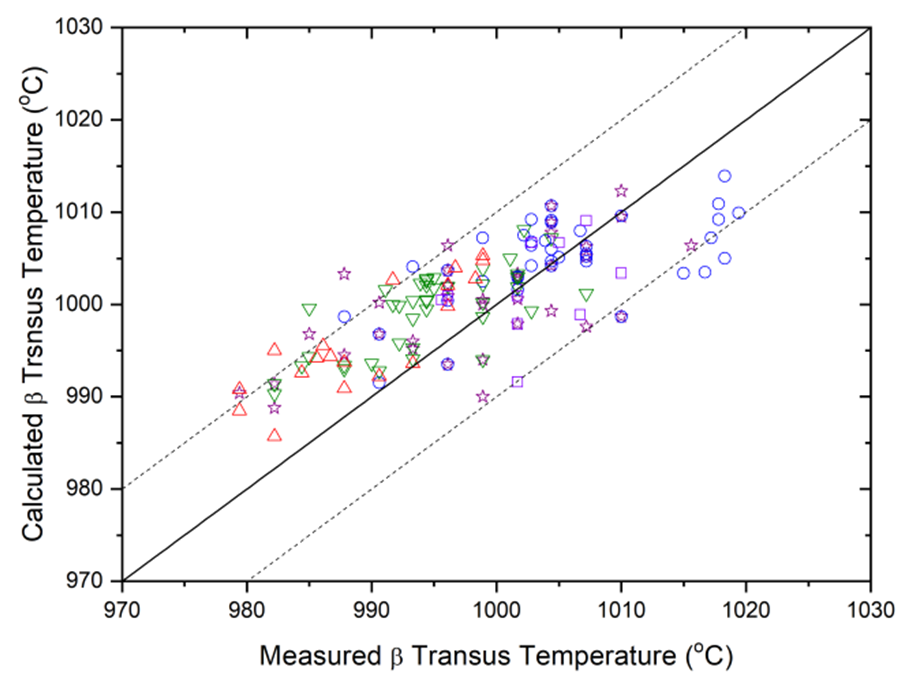

Comparison between predicted and observed beta transus for more than 150 Ti64 heats

Beta transus, the temperature at which α starts to form from β, is an important reference parameter in the selection of processing conditions, such as heat treatment process, for the conventional α-β type of titanium alloys. This temperature has been calculated for a large number of Ti64 and other titanium alloys using PanTi-TH. The example shows a comparison between the predicted and observed beta transus temperatures for more than 150 Ti64 heats, and reasonable agreement is obtained.

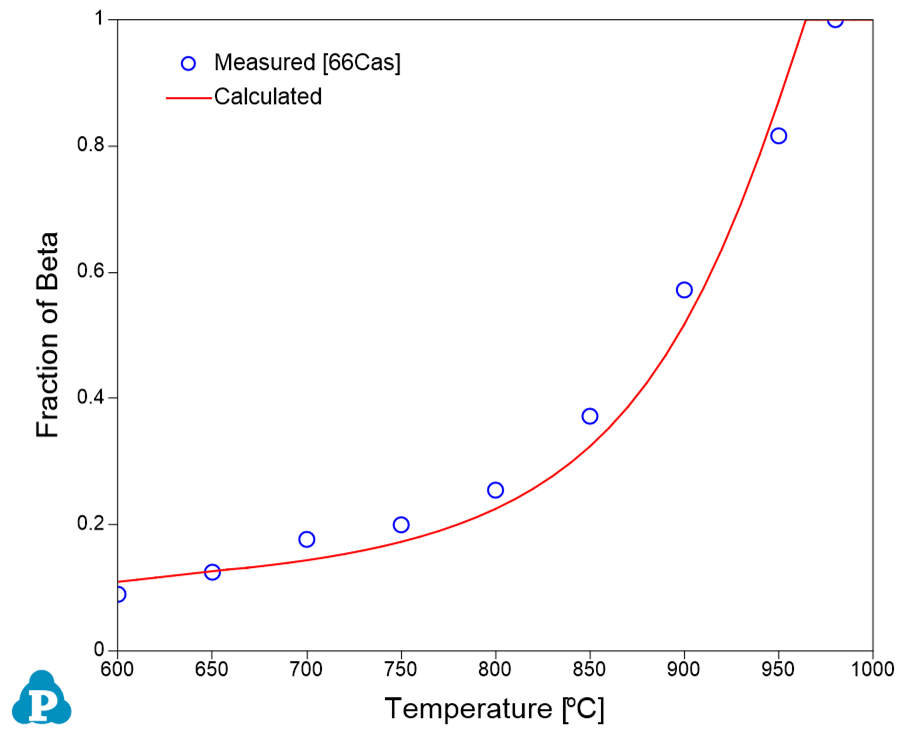

Calculated beta approach curve for a Ti64 alloy

This is an example of calculation of beta approach curve for a Ti64 alloy. The experimental data are also plotted on the figure for comparison.

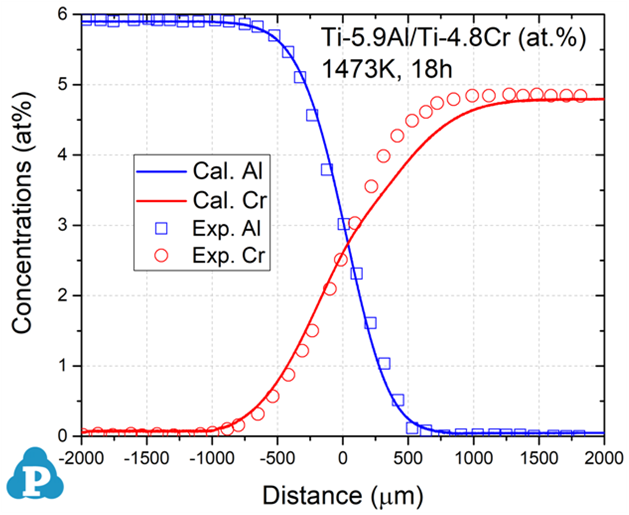

By integrating PanTi_MB and PanTi_MV with PanTi_TH, the combined database can be used to simulate diffusion-controlled phenomena and thermo-physical properties of titanium alloys. This example shows a simulation for diffusion couple Ti-5.9Al/Ti-4.8Cr (at%) annealed at 1473K for 18 hours.

Concentration profiles of Ti-5.9Al/Ti-4.8Cr (at.%) annealed at 1473K for 18h

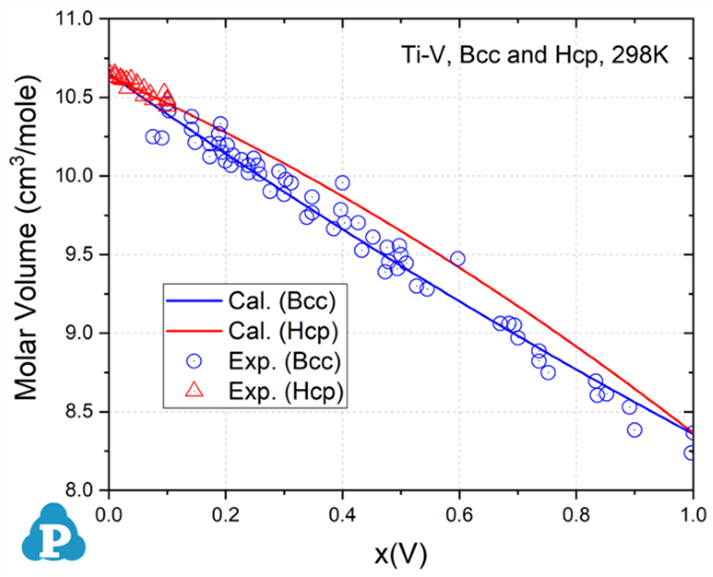

An example shows a calculation comparing the calculated and measured molar volume of Ti-V alloys in Bcc and Hcp.

Molar volume of Ti-V Bcc and Hcp binary alloys at 298K