Solidification simulation of an Al-Cu-Mg alloy for hot cracking susceptibility index prediction

- Purpose: Hot tearing or hot cracking is a serious defect occurred in welding and casting solidification. Cracking usually generated at the end stage of solidification along grain boundaries. Prof. Kou [2005Kou] proposed a criterion to describe the crack susceptibility by using a simple crack susceptibility index (CSI), which is the maximum value of |dT/d(fs)1/2| at fs1/2 < 0.99. The CSI criterion has been successfully applied in several Al alloy systems. In this example, users will learn how to perform solidification simulation of an Al-Cu-Mg alloy and output the relationship of |dT/d(fs)1/2| vs fs1/2 directly from Pandat, and thus determine the CSI value of the alloy. Users will also learn to set extra output tables with some specified properties and extra output plots from this example. Commercial database of PanAl.pdb including the thermodynamic and mobility data is required to perform the calculation of this example.

- Module: PanSolidification

- Database: PanAl2020_TH+MB.pdb; Al_Alloys.sdb

Calculation Method:

- Create a workspace and select the PanSolidification module following Pandat User’s Guide 2.1;

- Load PDB file PanAl2020_TH+MB through menu Database->Load TDB or PDB (Encrypted TDB) or by click icon

, and select the elements: Al, Cu, Mg.

, and select the elements: Al, Cu, Mg. - Load SDB file sdb through menu PanSolidification->Load SDB or by click icon

, select the available alloys: Al alloys.

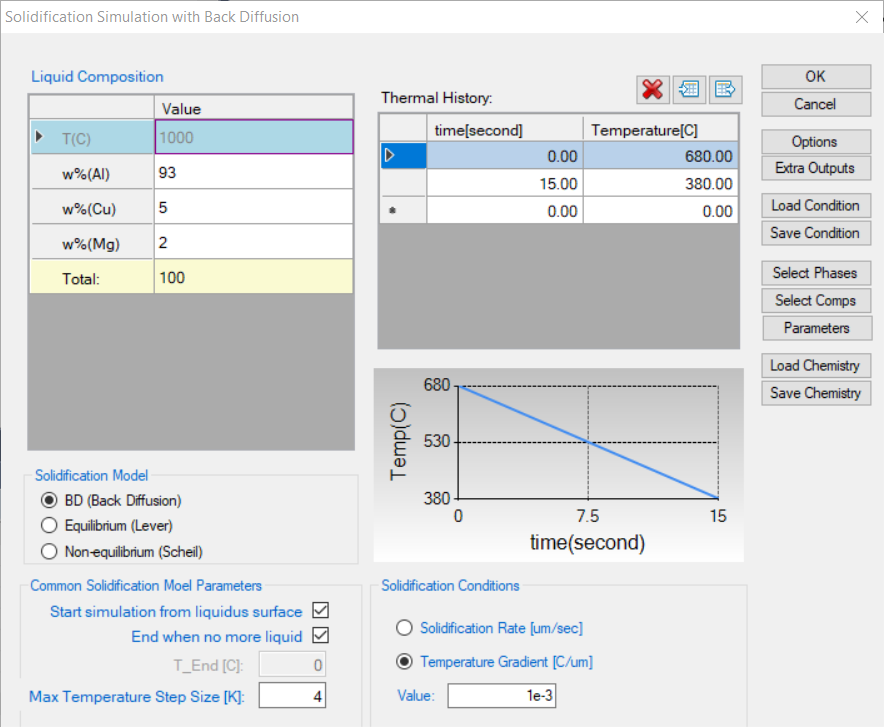

, select the available alloys: Al alloys. - Set Solidification simulation conditions as shown in Figure 1; The alloy composition is Al-5wt.%Cu-2wt.%Mg. The cooling rate is 20 K/s is setting in Thermal History solidifying from 680 °C to 380 °C with 15 second. Temperature gradient is set as 10-3 °C/μm. Please pay attention to the units of the time and length when set conditions.

Figure 1. Set up solidification conditions

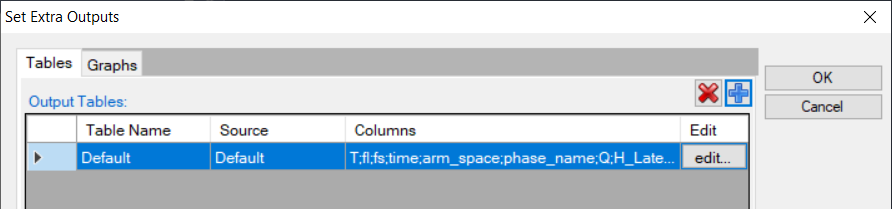

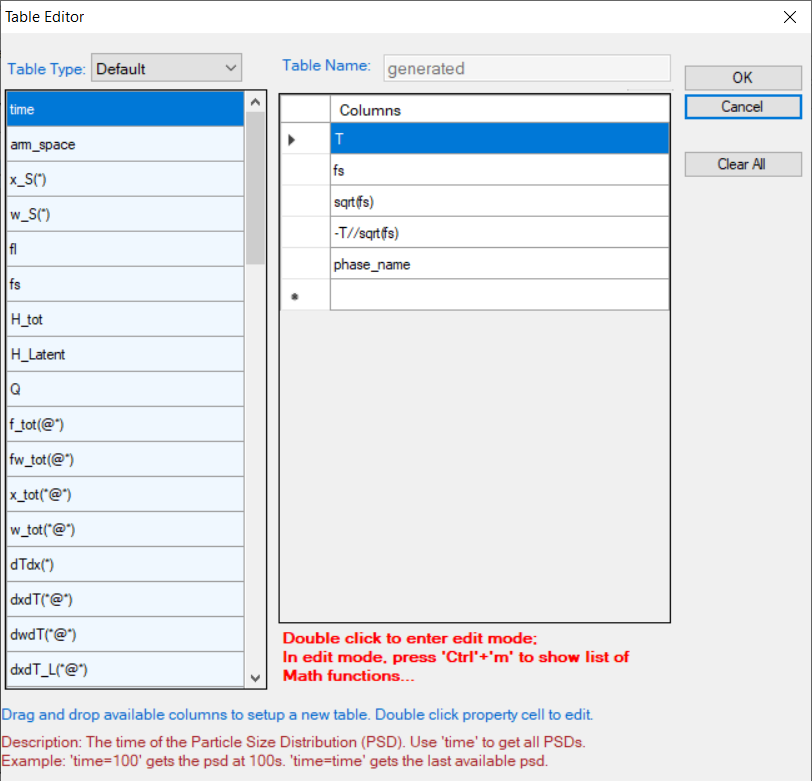

- Set “Extra Outputs table”. Click the “Extra Outputs” in Figure 1, a new interface as shown in Figure 2 will appear. Click the blue “+” symbol in Figure 2 to pop out the Table Editor as shown in Figure 3. From this Table Editor, users can specify and type in properties to output, such as sqrt(fs), -T//sqrt(fs) in this example. -T//sqrt(fs) refers to -dT/d(fs)1/2, as the syntax // means derivative in Pandat software. Note that with this setting, a “generated” table will be created in addition to the Default table.

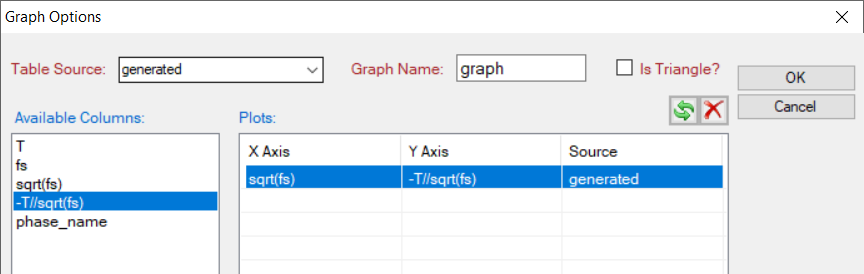

- Set “Extra Outputs graph”. Click the icon “Graph” in “Set extra output” interface as shown in Figure 2, then click the blue “+” symbol to add extra Graph. An interface as shown in Figure 4 will appear. Select the “generated” table generated by the previous step. Drag sqrt(fs) from the left column to X axis in the right column; drag -T//sqrt(fs) from the left column to Y axis in the right column. Then click OK. Note that with this setting, a “graph” of -T//sqrt(fs) vs. sqrt(fs) will be plotted automatically in addition to the Default graph.

- Then Click OK to perform Solidification simulation. (Detailed description also in Pandat User’s Guide 7.2).

Figure 2. Extra Output interface

Figure 3. Define properties in the extra output table

Figure 4. Define the axes of the extra graph

Post Calculation Operation:

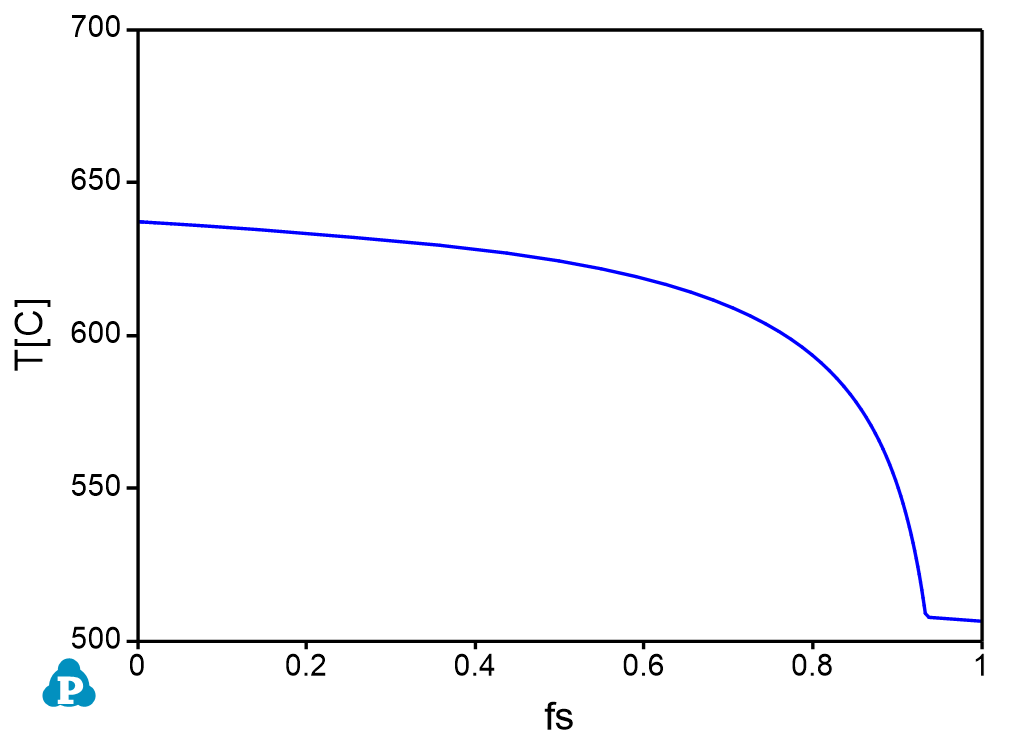

- The Default plot presents the relationship of temperature vs fraction of solid (fs) during solidification as shown in Figure 5.

Figure 5. Default plot showing the relation between temperature and fraction of solid

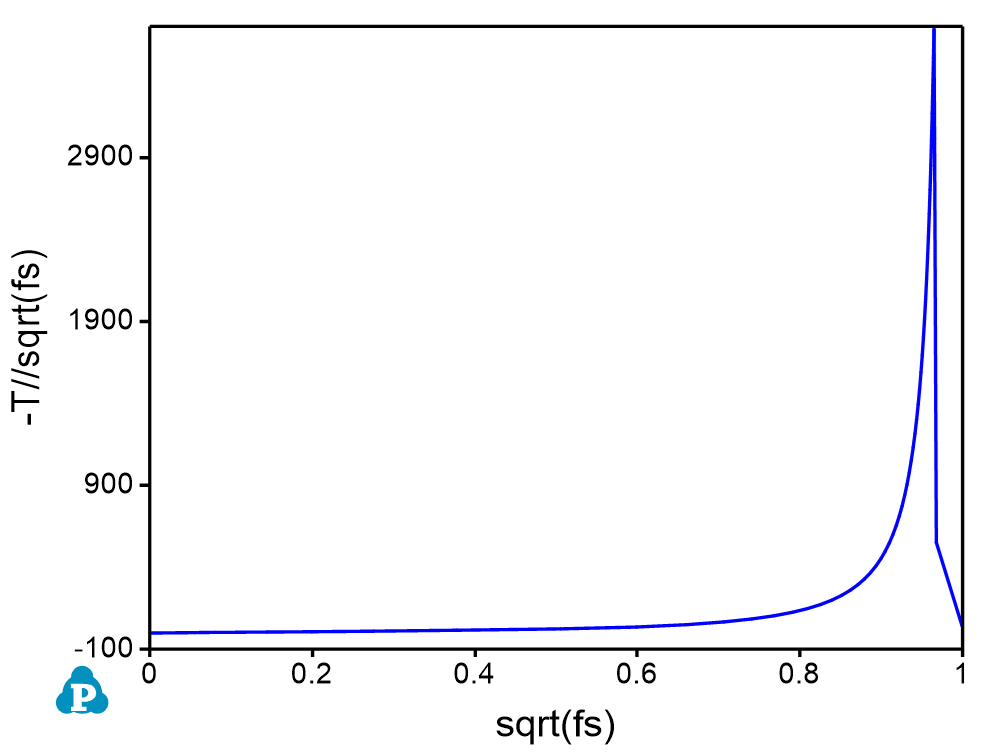

- The extra graph specified is plotted automatically as shown in Figure 6.

Figure 6. Extra plot specified by Extra Graph setting

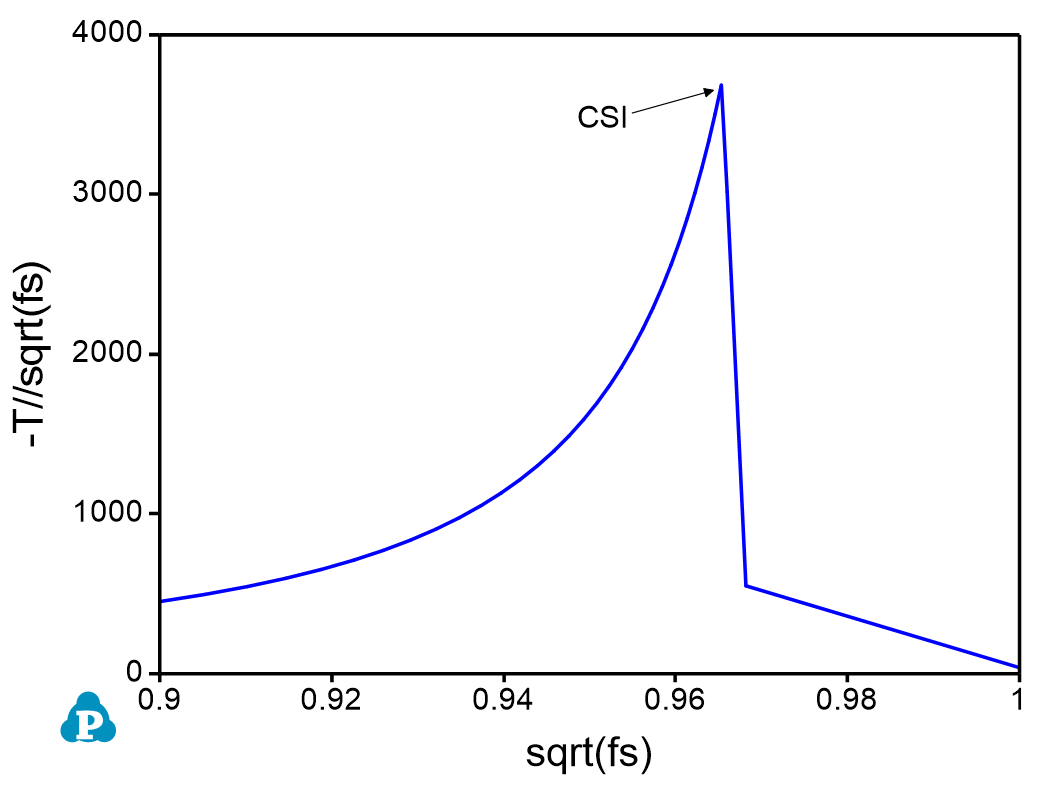

- Rescale Figure 6. as shown in Figure 7. The hot cracking susceptibility index (CSI) is defined as the maximum value of -dT/d(fs)1/2 with (fs)1/2 < 0.99.

Figure 7. Rescale of Figure 6 showing the maximum point of -T//sqrt(fs) with sqrt(fs) < 0.99.