Solutions for high entropy alloys

The high entropy alloys (HEAs), which are also often referred to as complex concentrated alloys (CCAs) and multi-principal element alloys (MPEAs), form a new concept for alloy design. Many empirical rules were proposed to predict the stability of solid solution phases in HEAs, yet the CALPHAD method provides the most convenient and reliable solution in this regard. Here we will use a few examples to demonstrate how one can use Pandat software and PanHEA database to optimize the alloy chemistry and processing conditions to achieve the desired properties for high entropy alloys.

Application Examples

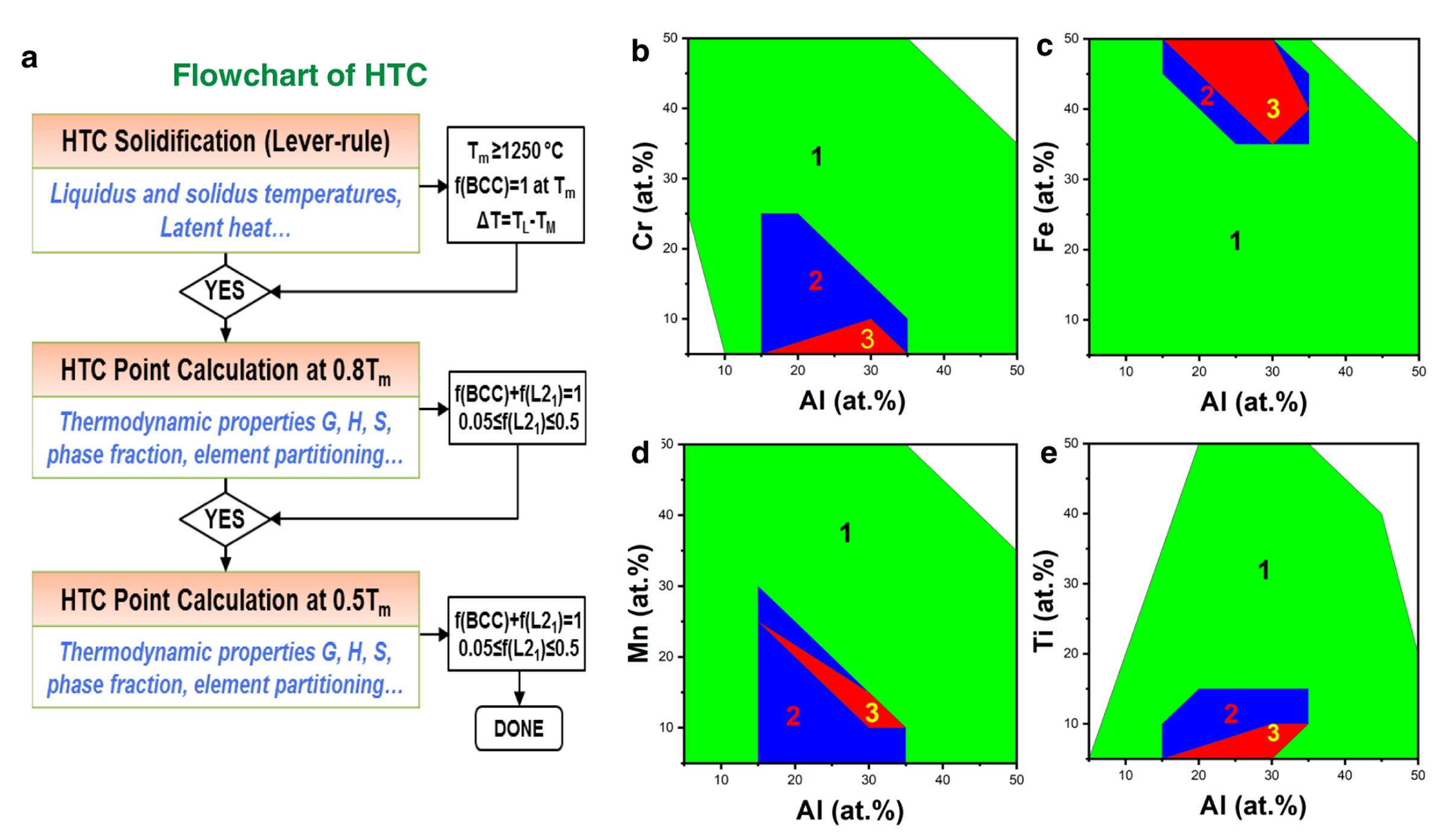

Calphad based high-throughput calculation (HTC) provides a powerful tool for explore high-entropy alloys (HEA) with targeted properties. The potential alloy compositions can be screened out from thousands of initial compositions. This figure shows the flowchart and results of the high-throughput calculations in the Al-Cr-Fe-Mn-Ti system. Eight promising alloys are determined from more than three thousand initial alloy compositions. In this example, all the HTC calculations and results analysis are carried out in the PanPhaseDiagram module.

(Please refer Feng et al., Nat. Commun., 12 (2021) 4329 for details.)

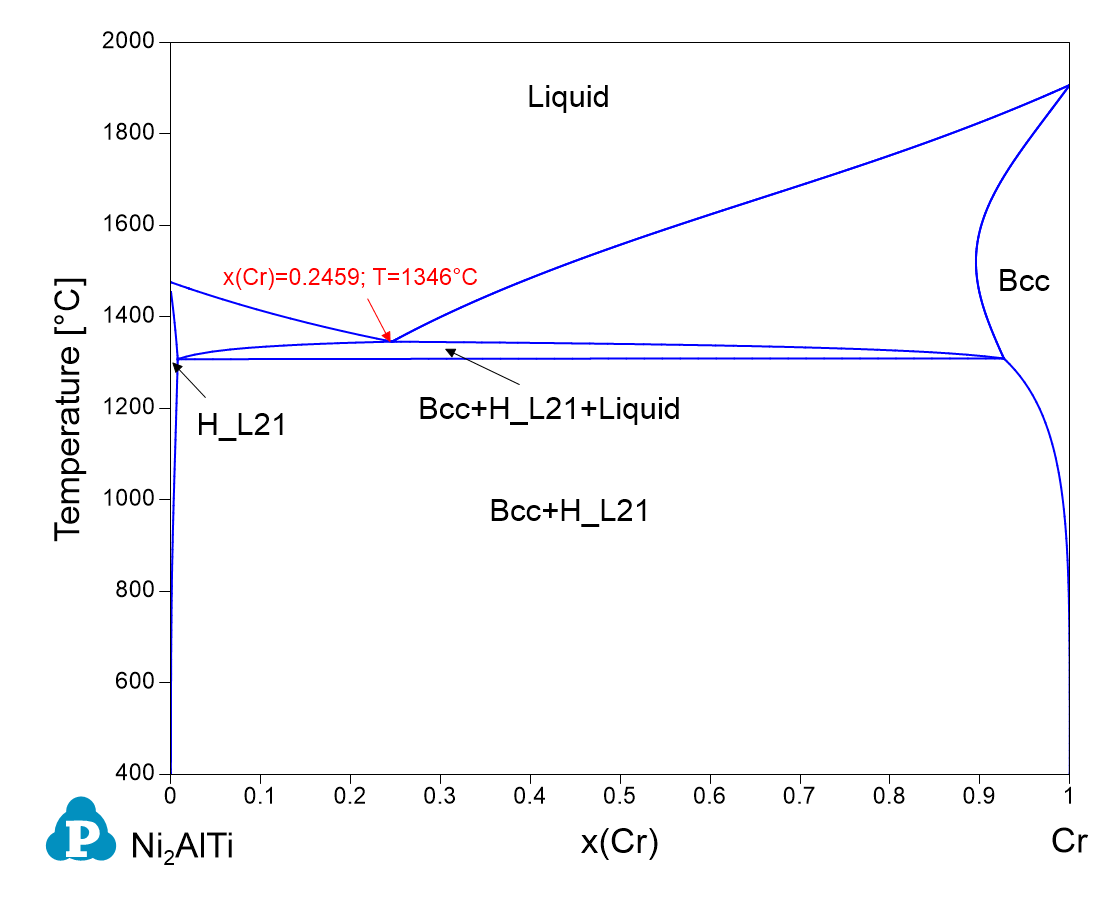

Design of eutectic high entropy alloy (EHEA)

The EHEAs, which combine the advantages of HEA and eutectic alloys, show good castability and excellent properties at elevated temperature. Using PanPhaseDiagram module of Pandat software, the eutectic composition and temperature can be easily identified. This figure shows the promising eutectic alloy along Ni2AlTi-Cr section.

More publications on using Pandat software to design EHEA:

Wang et al. Scr. Mater., 204 (2021) 114132

Wu et al. Mater. Lett., 262 (2020) 127175.

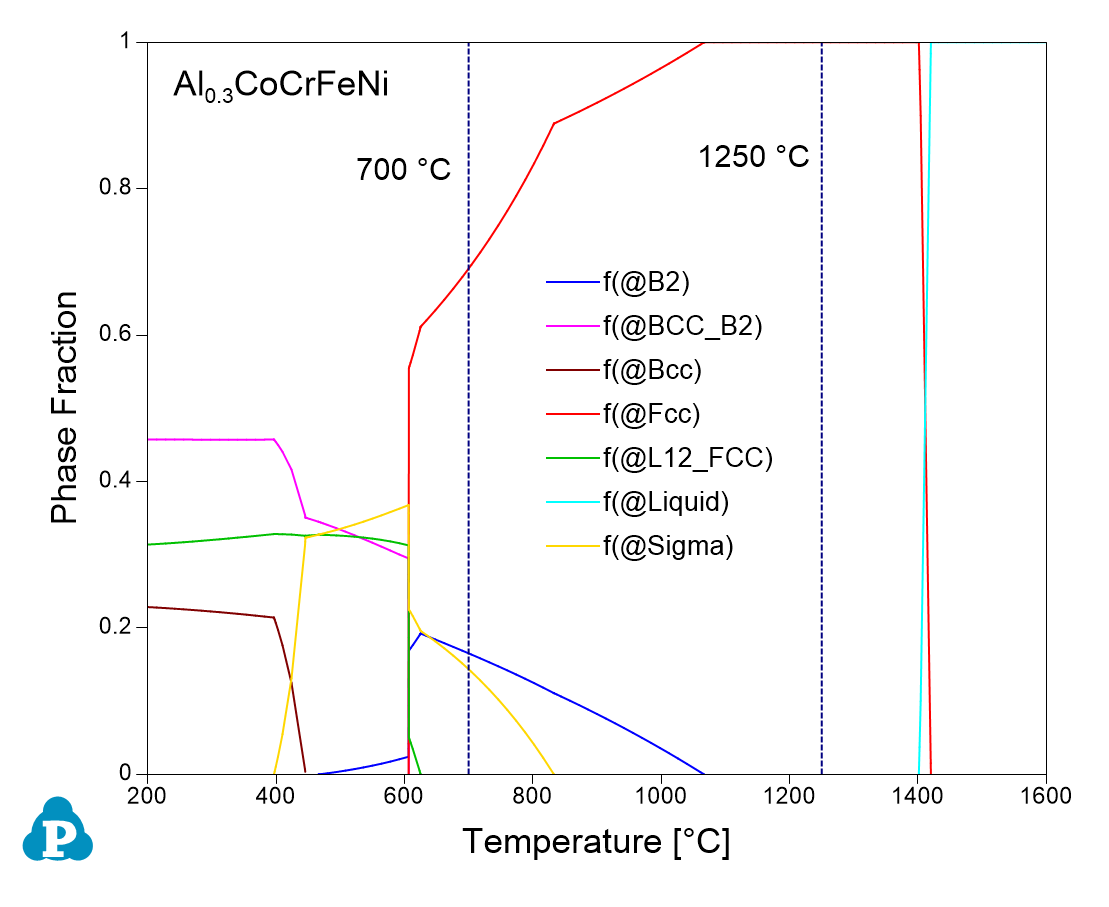

Novel NiAl strengthened HEA with balanced tensile strength and ductility

Single Fcc phase HEAs often have low yield strength. The precipitate-strengthened Al0.3CoCrFeNi alloy exhibits enhanced yield strength with good ductility. This figure calculated from the PanPhaseDiagram module of Pandat software shows the precipitation of B2 and σ phase after aging at 700 °C.

Please refer Diao et al. Mater. Sci. Eng. A, 742 (2019) 636-647 for details.

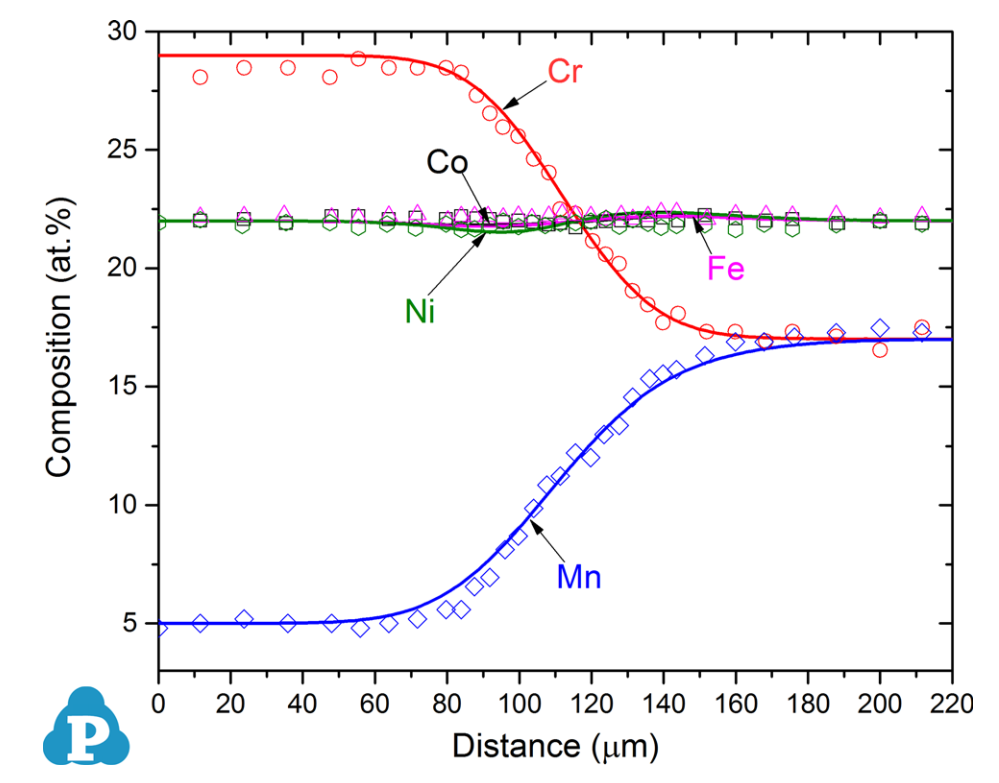

Elemental Diffusion Behavior in HEA

The so-called “sluggish diffusion effect” is featured as one of the core effects of HEAs. Diffusioin simulation would provide a better understanding on the overall picture of the HEAs. This figure shows the simulated results of two HEAs (Co22Cr29Fe22Mn5Ni22/ Co22Cr17Fe22Mn17Ni22 (at.%)) diffusion couple annealed at 1000 °C for 100 h. The simulation uses the validated PanHEA mobility database and PanDiffusion module in Pandat software.

Please refer Zhang et al., J. Phase Equilib. Diffus., 38 (2017) 434-444 for more details.

Still have question? Contact us to find a solution for your applications.