PanAluminum

Database for multi-component Aluminum-rich casting and wrought alloys

- Thermodynamic

- Mobility

- Thermophysical Property: Molar Volume; Surface Tension; Viscosity

PanAluminum

PanAluminum Quick Overview

-

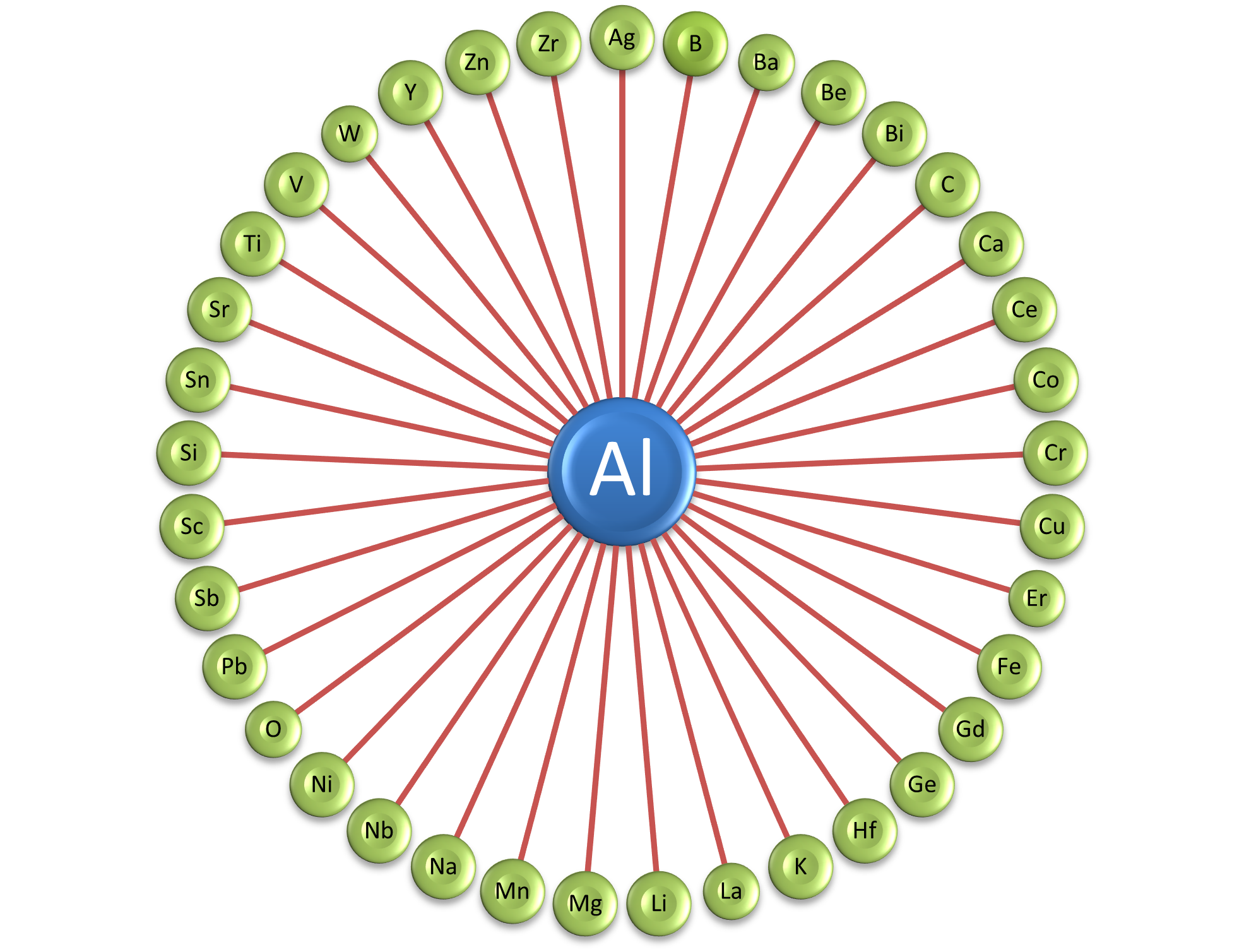

Number of components: 39

-

Number of phases: 1191

-

Major alloying elements: Al, Cu, Fe, Mg, Mn, Si and Zn

-

Minor alloying elements: Ag, B, Ba, Be, Bi, C, Ca, Ce, Co, Cr, Er, Gd, Ge, In, Hf, K, La, Li, Na, Nb, Ni, O, Pb, Sb, Sc, Sn, Sr, Ti, V, W, Y, and Zr

PanAluminum – Thermodynamic database (TH), Mobility database (MB), and Molar volume (MV) database for multi-component aluminum-rich casting and wrought alloys.

- The PanAl_TH thermodynamic database consists of 39 components, 1191 phases, 469 assessed binary systems and 83 assessed ternary systems. The database is validated by large number of aluminum alloys.

- The PanAl_MB mobility database includes assessed mobility model parameters for the Liquid, Bcc, Fcc, and Hcp solution phases. It is compatible with the PanAl_TH and suitable for the simulation of diffusion controlled phenomena of multi-component aluminum alloys.

- The PanAl_TP thermophysical property database includes the molar volume database covers all the phases assessed in the PanAl_TH, the surface tension and viscosity properties for the liquid phase. It can be combined with the thermodynamic database for the simulation of thermo-physical properties of Al-based alloys, such as density, thermal expansion, and solidification shrinkage.

Applications

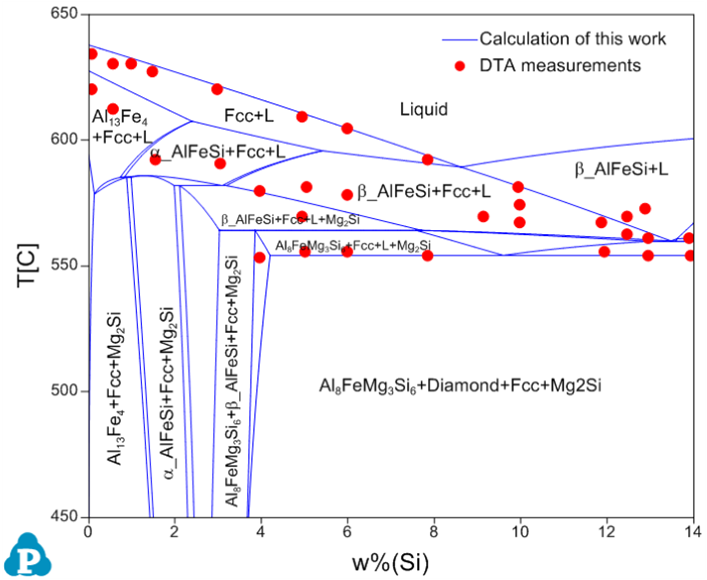

Calculated isopleth of Al-Si-0.5Fe-4Mg(at%)

This figure shows the calculated isopleth of Al-Fe-Mg-Si at 4wt.%Mg and 0.5wt.%Fe with experimental data.

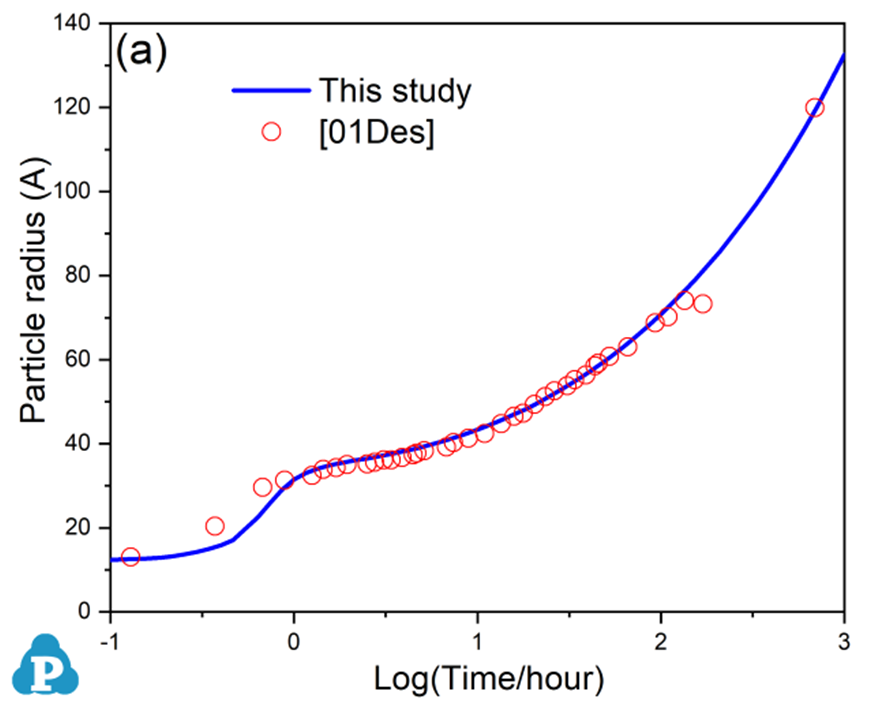

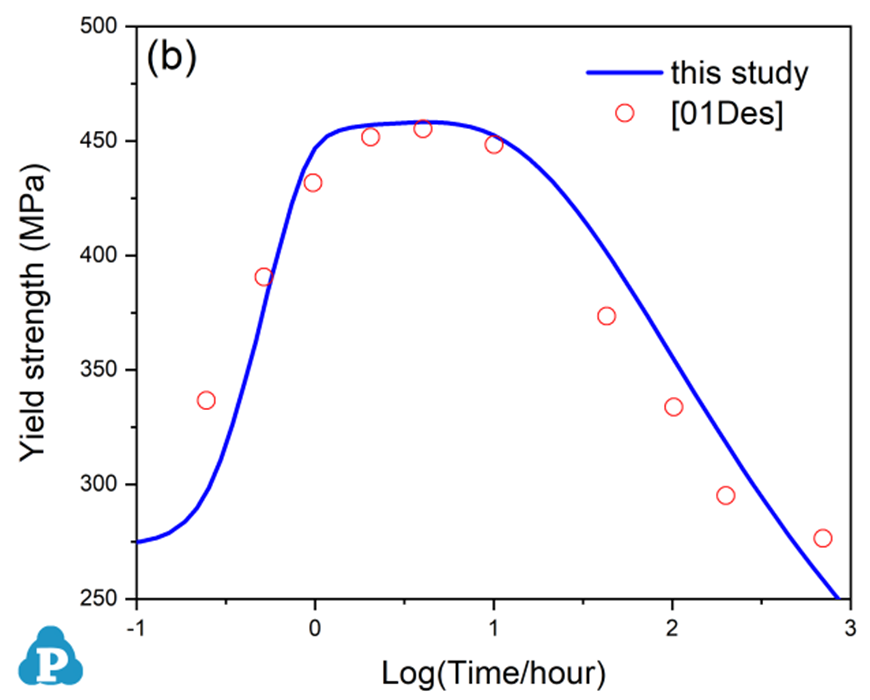

A precipitation simulation for the Al-2.3Mg-6.1Zn (wt%) alloy aged at 160oC for 1000 hours. The simulated particle size and yield strength evolution with time are compared with experimental data as shown in the figures. As is seen, the particles grow and coarsen with ageing time, while the yield strength reaches peak between 1 to 10 hours and decreases quickly after 10 hours of ageing. The database used to do this simulation is the combined thermodynamic and mobility database of Al-based alloys: PanAl_TH+MB.

Simulated and measured particle size and yield strength evolution with time for the Al-2.3Mg-6.1Zn (wt%) alloy aged at 160oC for 1000 hour

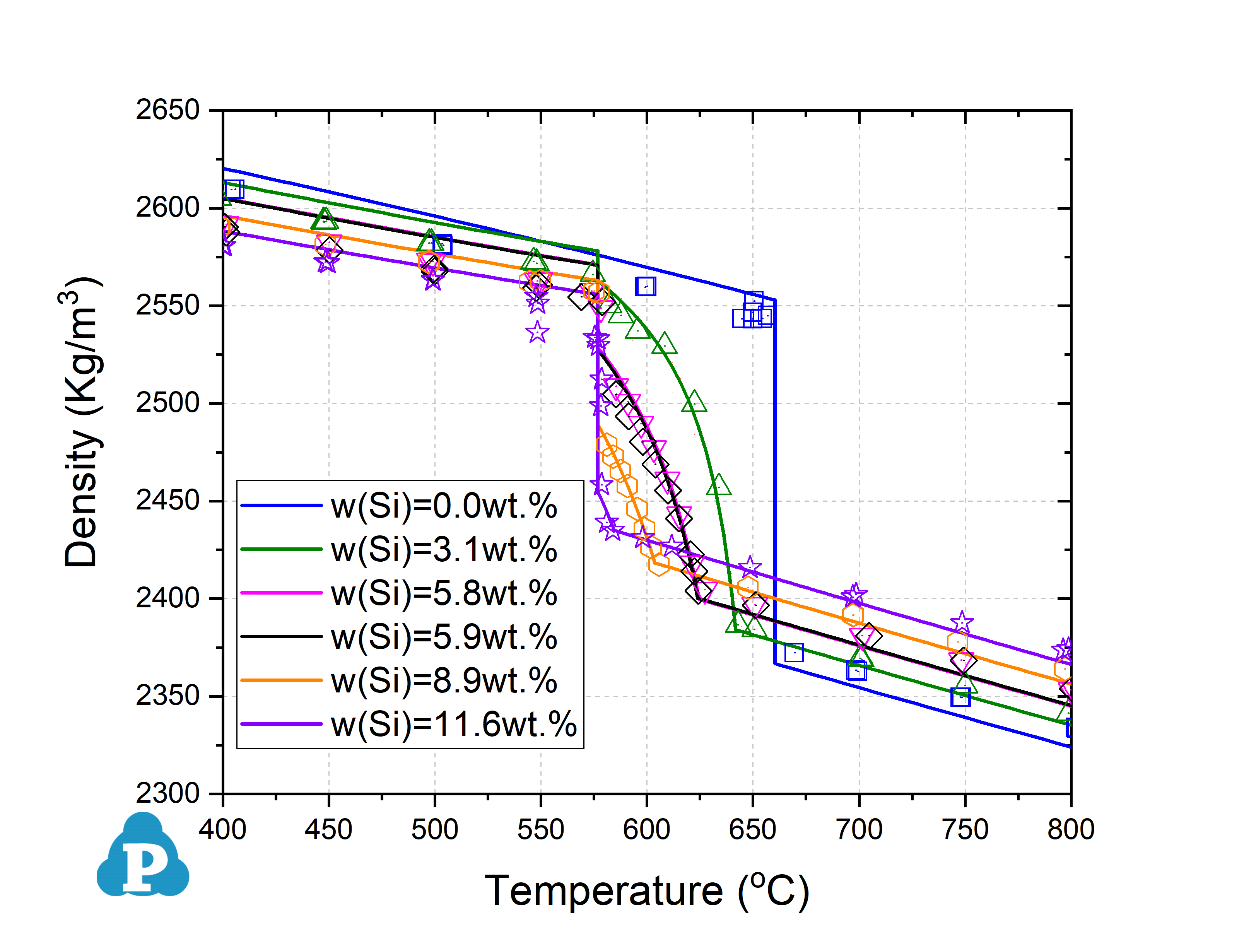

The simulated density changes vs. temperature of a series of Al-based alloys.

The calculated densities of Al-Si alloys at various compositions using the PanAl_TH+MV combined thermodynamic and molar volume database