Solutions for Irons and Steels

The Fe-based alloys cover a broad range of materials, which can be subdivided into cast irons, stainless steels, high-speed steels, tool steels, low-density steels and so on. A few examples are presented here to demonstrate how one can use Pandat software and PanFe database to optimize the alloy chemistry and processing conditions to achieve the desired properties for steel alloys.

Application Examples

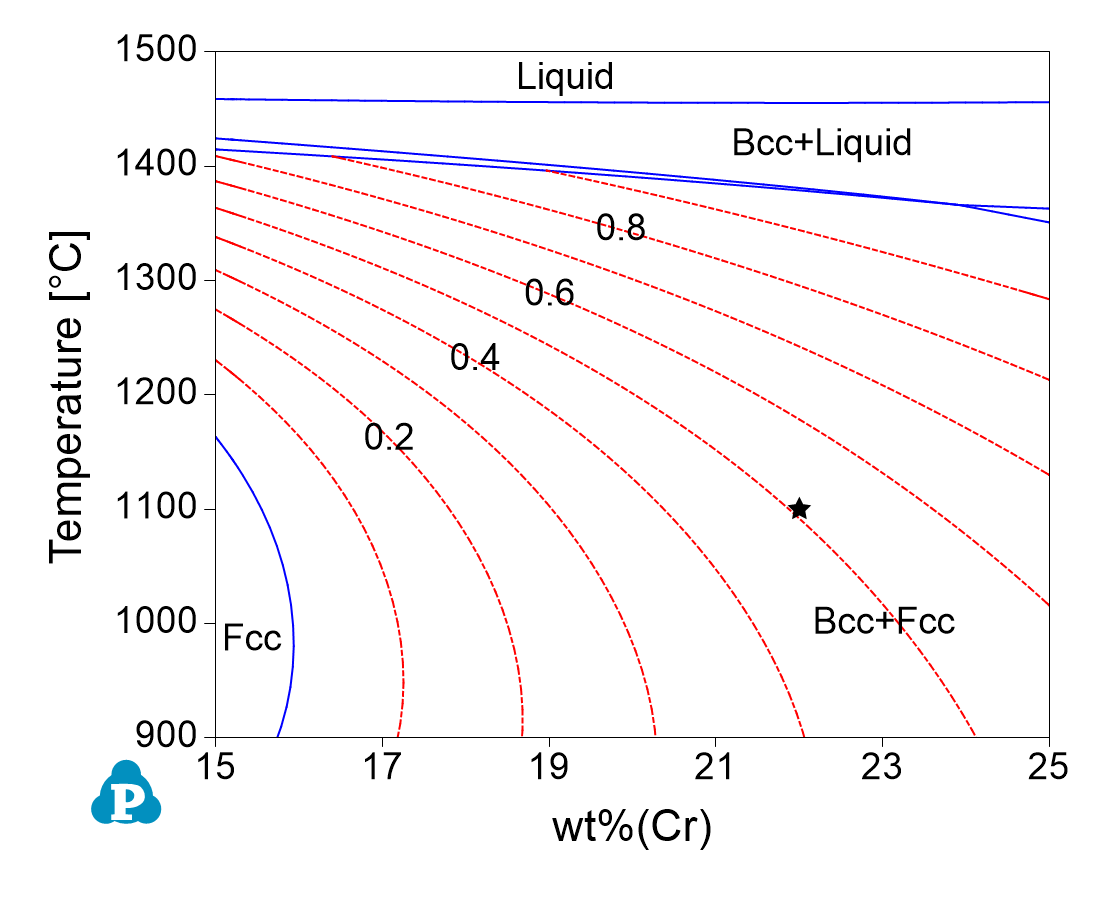

Application in Duplex stainless steel

Duplex Stainless Steel often refers to the steel that has equal amount of austenite and ferrite. The amounts of austenite and ferrite depend on the alloy composition and the heat treatment temperature. This figure shows an isopleth of Fe-5Ni-3Mo-1.2Mn-0.7Si-0.16N-0.02P-xCr (wt.%) system. Using the contour line functionality in PanPhaseDiagram module, the phase fractions can be plotted on the normal phase diagram which allows a user to quickly select the composition and heat treatment temperature to develop duplex structure. The typical 2205 duplex stainless steel is marked as star with Cr 22% and heat treatment temperature of 1100 °C.

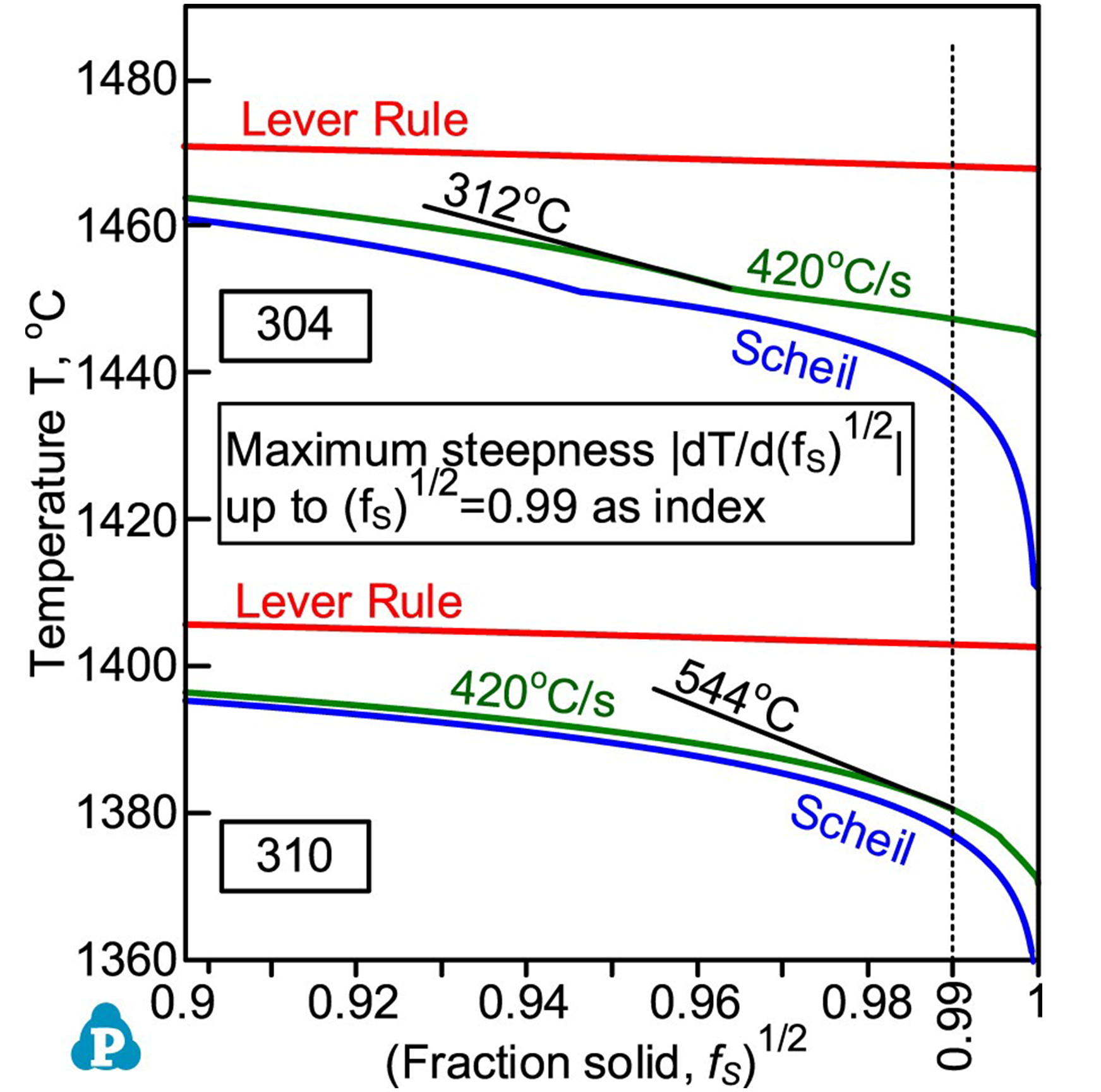

Solidification cracking in steels

Austenitic stainless steels resist solidification cracking much better if ferrite (δ) is the primary solidification phase instead of austenite (γ). Why? This figure calculated from the PanSolidification module shows that back diffusion of Cr and Ni in bcc(δ) is much faster than that in fcc(γ). This flattens the curve much more in 304 than in 310 steelwhich reduces the crack susceptibility index |dT/d(fS)1/2| near fs = 1 in 304 than in 310. This is consistent with experimental observation. Please refer to Liang et al. Sci. Technol. Weld. Joining, 26 (2021) 606-613 and Xia and Kou, Metall. Mater. Trans. B, 52 (2021) 460-469 for details.

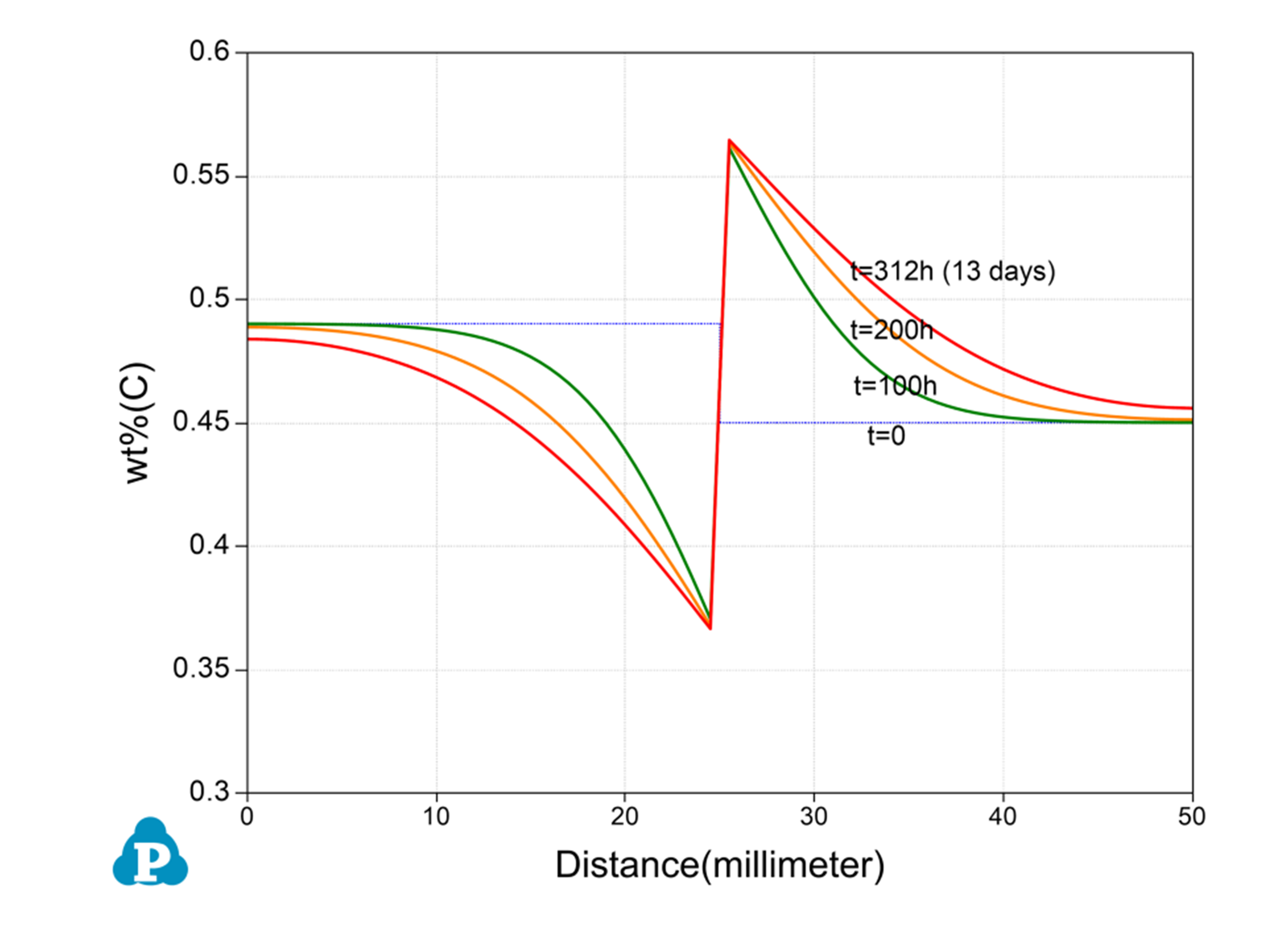

Uphill diffusion in Fe-Si-C alloy

This figure shows the uphill diffusion occurred between the Fe-3.8Si-0.49C and Fe-0.05Si-0.45C (wt.%) alloy interface. The simulation is performed by PanDiffusion module of Pandat software. Please refer example 4.11 in the example book for details.

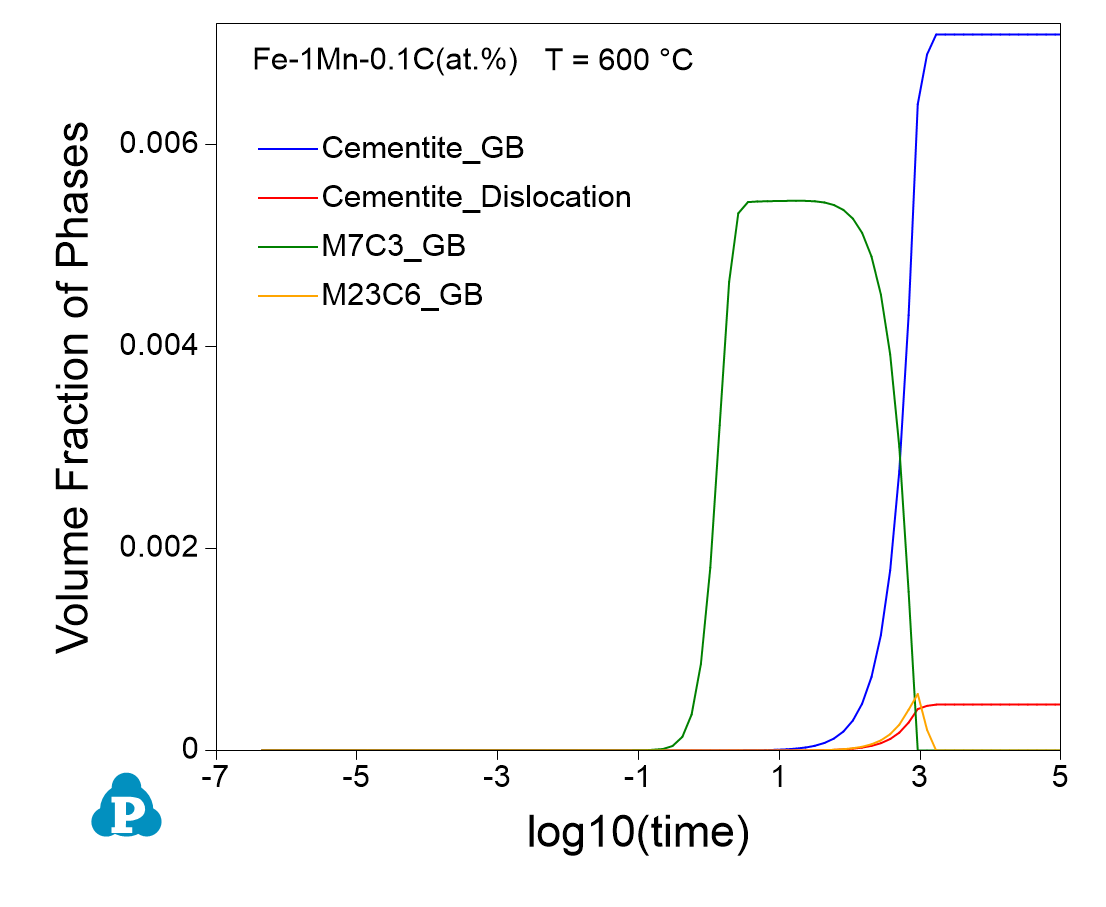

Multiple phase precipitations in steel

The precipitation procedure in steel is complicated. PanPrecipitation module can consider precipitates at different locations. This figure shows the precipitations occur at grain boundary (GB) and dislocation simulated by PanPrecipitation module.

The simulation files required in this simulation are included in the Pandat Example folder (…\CompuTherm LLC\Pandat 202x\Pandat 202x Examples\PanPrecipitation\Fe-Mn-C_Heterogeneous_ Nucleation).

Still have question? Contact us to find a solution for your applications.