PanEvolution

The new PanEvolution module (an extension of the previous PanPrecipitation) enables the concurrent simulation of dislocation density, recrystallization, grain coarsening, in addition to the traditional precipitation simulation. The module is seamlessly integrated with the thermodynamic calculation engine, PanEngine, for the necessary thermodynamic input and mobility data. It is built as a shared library and integrated into Pandat™ as a specific module that extends the capability of Pandat™ for kinetic simulations, while taking full advantage of the automatic thermodynamic calculation engine (PanEngine) and the user- friendly Pandat™ Graphical User Interface (PanGUI).

PanEvolution

- recrystallization and grain growth

- precipitation and grain growth

- multi-phase co-precipitation

- TTT curves

Some Key Features of PanEvolution Module

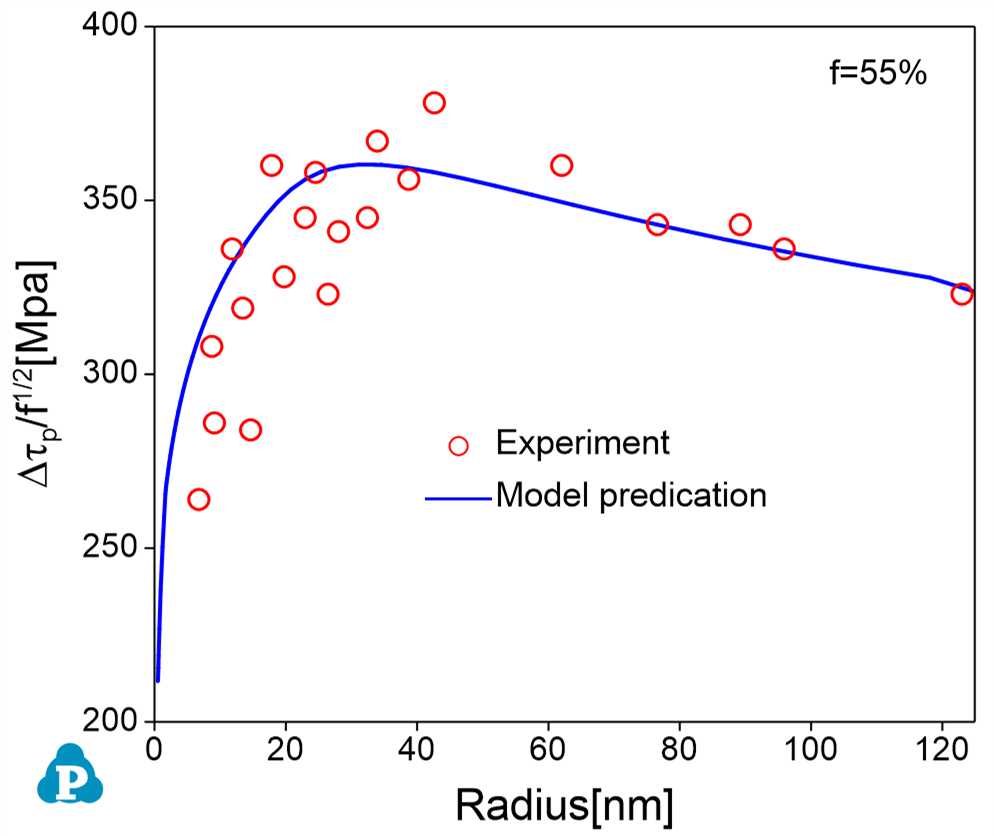

Critical resolved shear stress for nickel alloy Nimonic 105.

- Particle size evolution: average particle size evolution under various heat treatment conditions

- Particle size distribution: particle size distribution at selected time stages

- Heterogeneous nucleation: heterogeneous nucleation at grain boundary/edge/corner or at dislocations

- Evolution of aspect ratio: evolution of aspect ratio due to direction dependent interfacial energy and anisotropic misfit strain energy

- Input of initial microstructure: allows user to input the Initial microstructure, such as the precipitate size, fraction and distribution

- Strength model: precipitation hardening and strengthening behavior

- Grain growth: Consider the Zener pinning effect

- Dynamic recrystallization process: flow stress curve simulation

- TTT diagram: time-temperature-transformation plots of precipitates