2025 Newsletter

2025 Newsletter

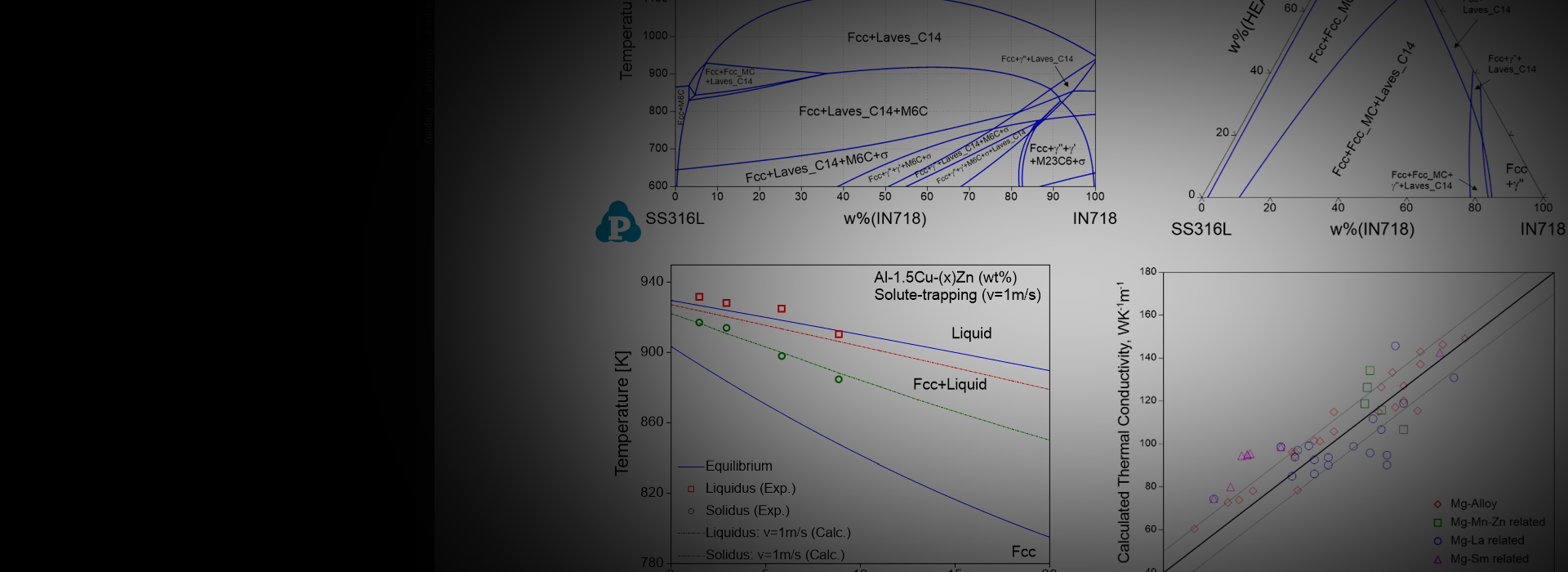

Material to Material Calculations

Solute Trapping Model for PanSolidification Simulations

New Databases for Molten salt and Thermal Conductivity

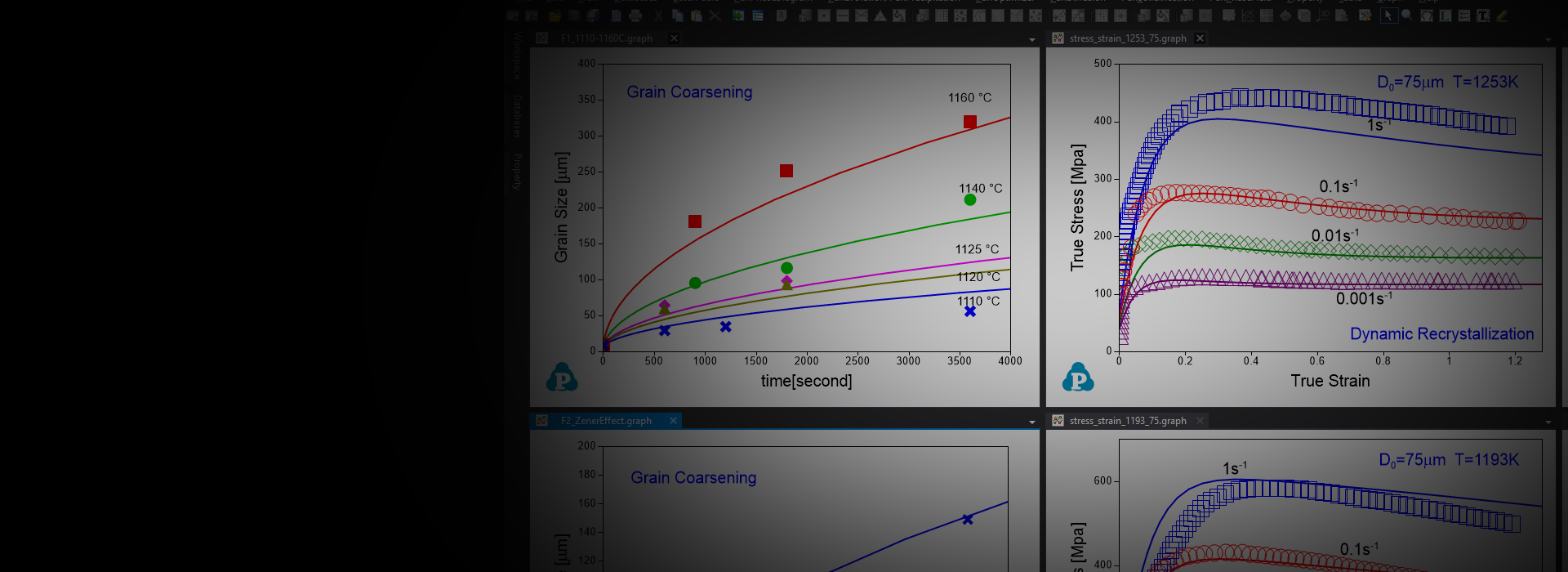

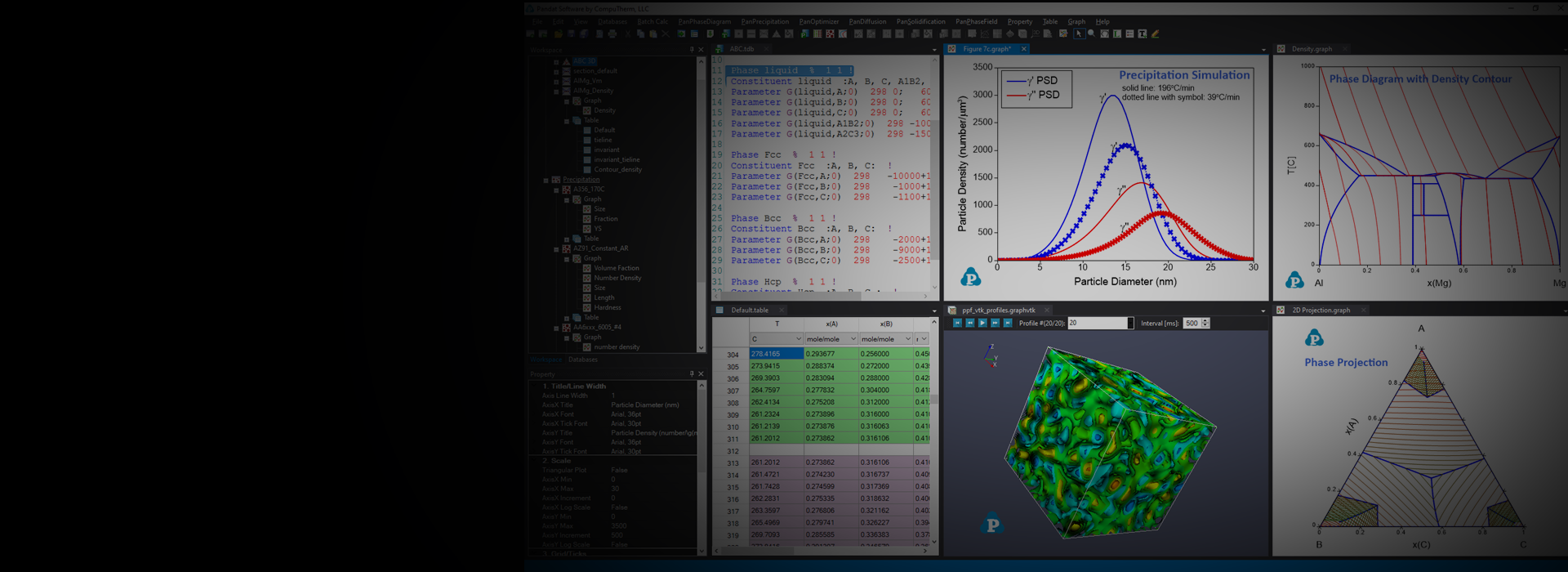

Concurrent Grain Growth and Precipitation Simulation

Precipitation Simultion

TTT and CCT Curves

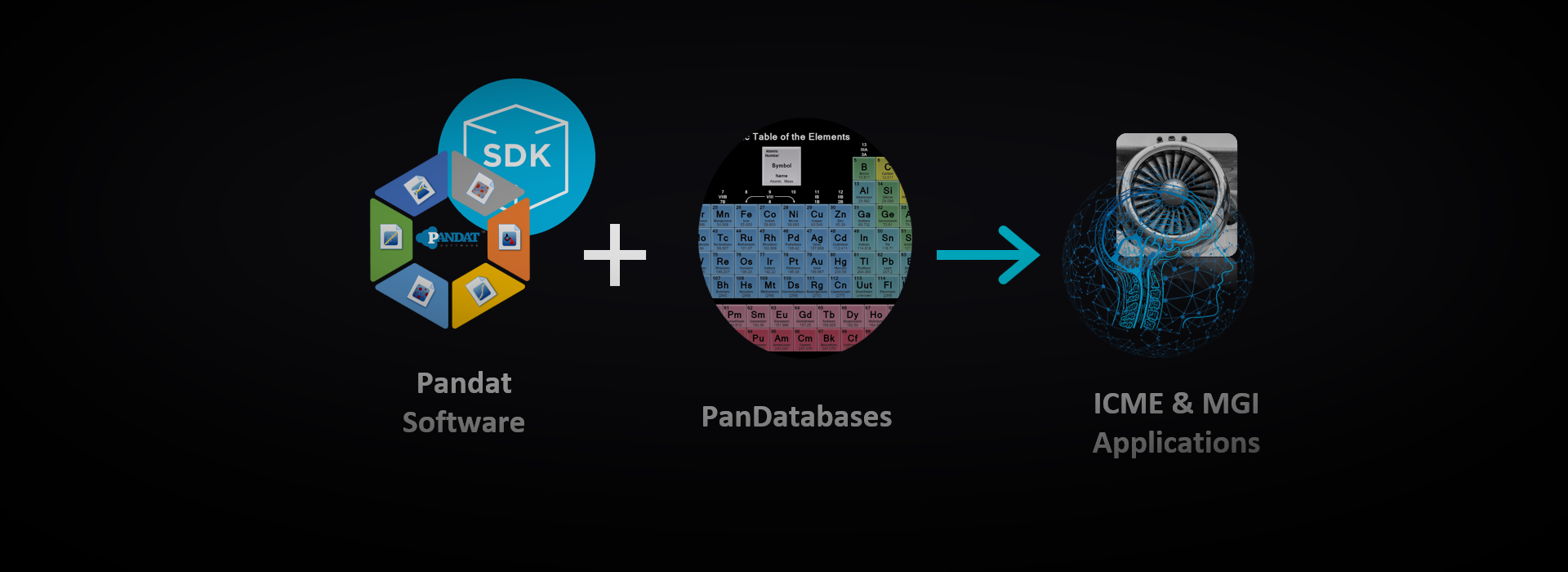

Easy Coupling with Other ICME Tools

One Unified Workspace, Numerous Materials Data

Object-Oriented Design and Written in C++

Simple and Easy to Use API Functions

Flexible Materials Data Management

Customizable Table with Export Function

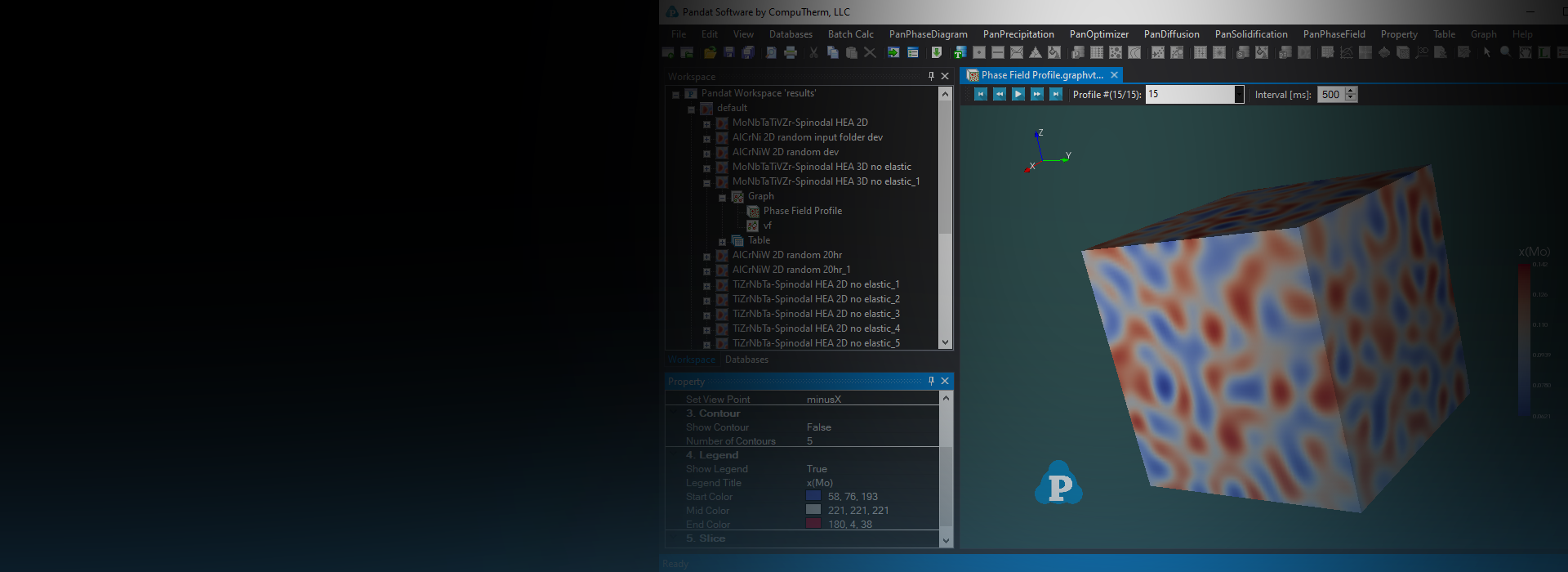

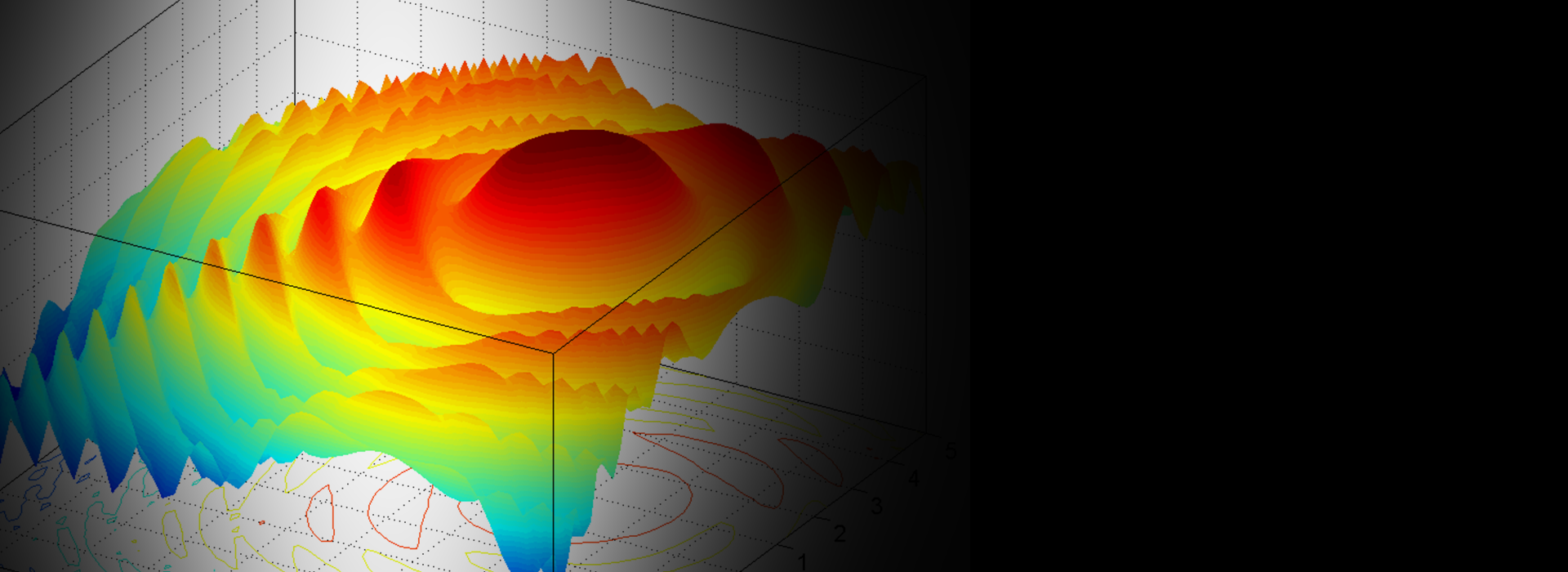

High Quality and Customizable Graph in 2D/3D

Pandat Software Modules

Pandat Software adopts modular design and enables users to easily switch between modules and perform various types of simulations in the same workspace.

- stable and metastable diagrams

- property contour diagrams

- thermodynamic properties

- chemical driving force

- material to material diagrams

- particle concurrent nucleation, growth and coarsening

- multi-phase co-precipitation

- precipitation and grain growth

- recrystallization and grain growth

- TTT and CCT curves

- diffusion couple

- homogenization

- carburization and decarburization

- particle dissolution

- Optimization of thermodynamic, kinetic and thermo-physical model parameters using experimental data

- solidification path

- back-diffusion in the solid

- dendrite arm coarsening

- micro-segregation

- solute trapping effect

- direct coupling with CALPHAD

- feasible for multi-component alloys

- open architecture for user’s model plugin