PanNickel

Thermodynamic Database for Nickel-Based Superalloys

- Thermodynamic

- Mobility

- Thermophysical Property: Molar Volume; Surface Tension; Viscosity

PanNickel

PanNickel Quick Overview

-

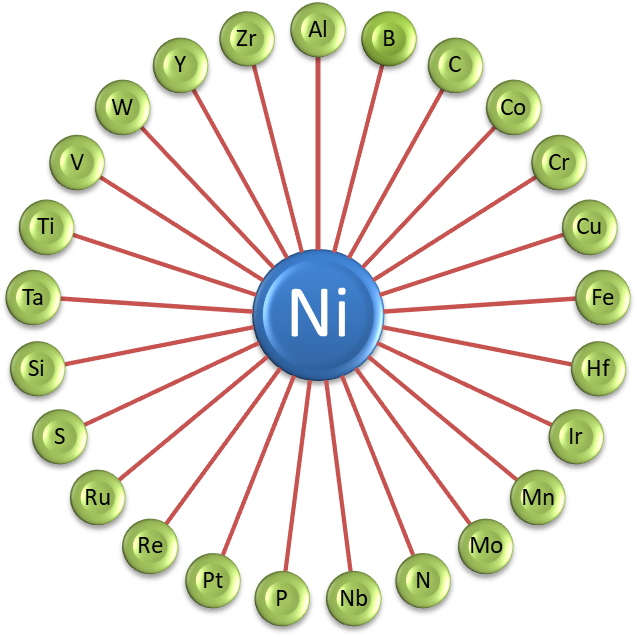

Number of components: 27

-

Number of phases: 343

-

Alloying elements: Al-B-C-Co-Cr-Cu-Fe-Hf-Ir-Mn-Mo-N-Nb-Ni-O-P-Pt-Re-Ru-S-Si-Ta-Ti-V-W-Y-Zr

PanNickel – Thermodynamic database (TH), Mobility database (MB), and Thermophysical property (TP) database for multi-component nickel alloys.

- The PanNi_TH thermodynamic database consists of 27 components, 343 phases and 314 fully assessed binary and ternary systems. The database is validated by many Ni-based superalloys.

- The PanNi_MB mobility database assessed mobility model parameters for the Liquid, Bcc, Fcc, and Hcp solution phases. It is compatible with PanNi_TH and suitable for the simulation of diffusion controlled phenomena of multi-component nickel alloys.

- The PanNi_TP thermophysical property database includes the molar volume database covers all the 343 phases assessed in the PanNi_TH, the surface tension and viscosity properties for the liquid phase. It can be combined with the thermodynamic database for the simulation of thermo-physical properties of Ni-based alloys, such as density, thermal expansion, and solidification shrinkage.

Applications

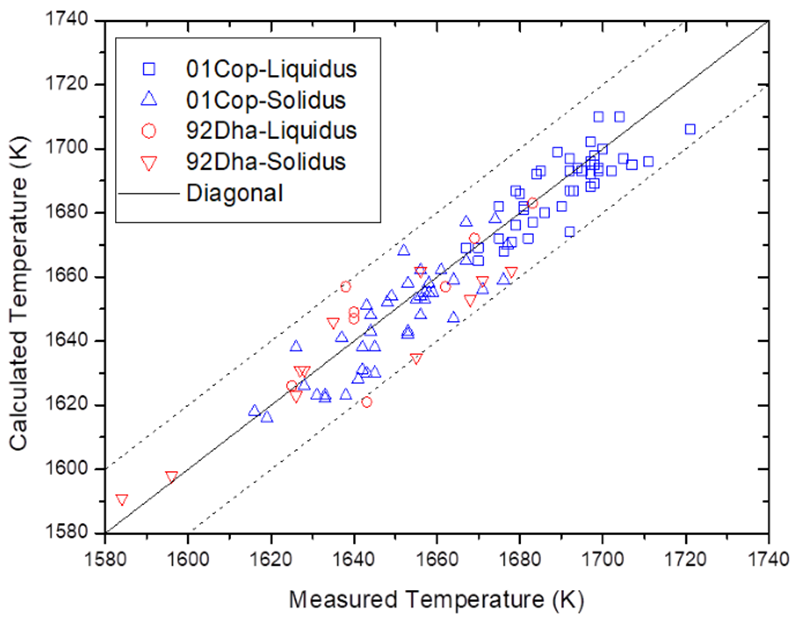

Comparison between the calculated and measured liquidus and solidus temperatures

A comparison between the calculated and measured liquidus and solidus temperatures for nickel-based superalloys.

Comparison between the calculated and experimentally determined activity of Al in the Ni-Al-Pt and Ni-Al-Cr-Pt systems

A comparison between the calculated and experimentally determined activity of Al in the Ni-Al-Pt and Ni-Al-Cr-Pt systems.

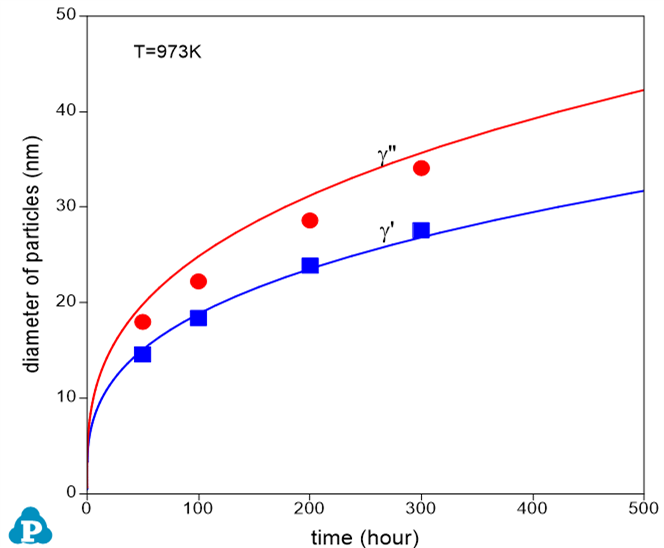

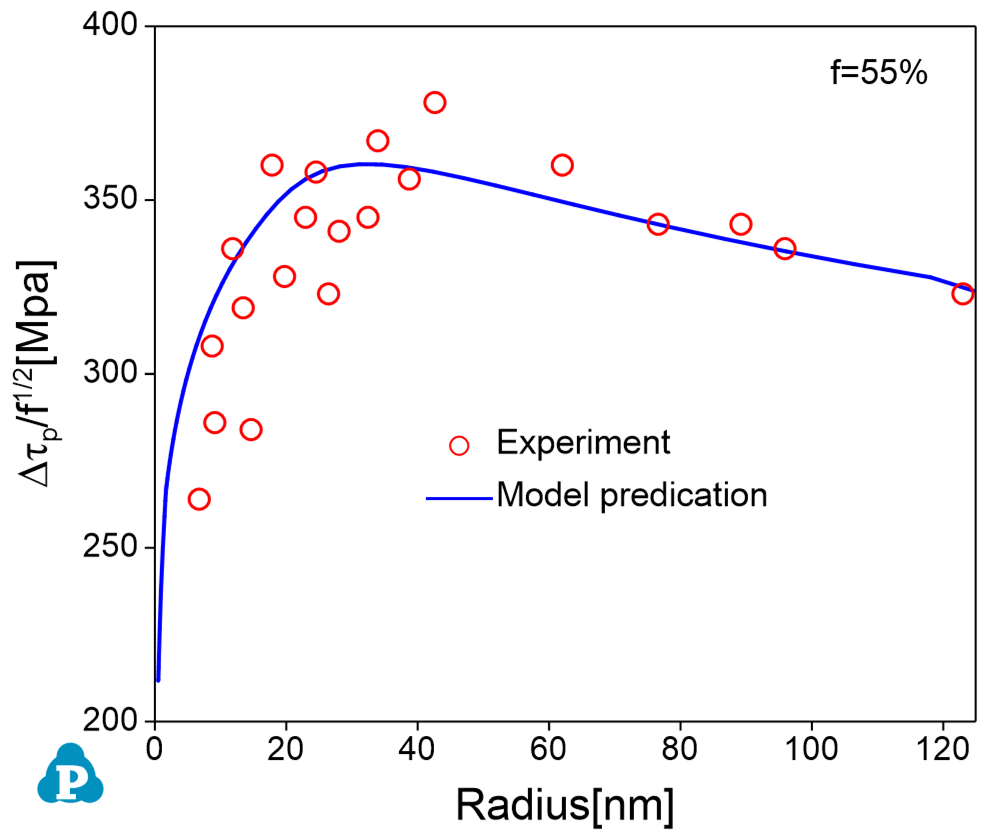

By integrating PanNi_MB and PanNi_MV with PanNi_TH, the combined database can be used to simulate diffusion-controlled phenomena and thermo-physical properties of nickel-based superalloys. The example shows the simulation of particle size evolution of co-precipitation of γ’ and γ”. The lower figure shows an example of calculated critical resolved shear stress for a nickel alloy Nimonic 105 using the strength model developed for nickel-based alloys considering particles of multiple particle size groups with weak/strong pair coupling or bowing mechanisms.

Particle evolution of γ’ and γ” co-precipitation in nickel-based superalloy 718

Calculated and experimentally determined critical resolved shear stress for a nickel alloy Nimonic 105