Solutions for Aluminum alloys

Aluminum alloys are usually classified as casting alloys and wrought alloys. The typical alloying elements are Cu, Mg, Zn, Si, Mn, Ni, and Sn, while other alloying elements and impurities may also be included in aluminum alloys. The properties of aluminum alloys are very sensitive to the alloy composition and strongly depend on the solidification procedure and thermal history. A few examples are presented here to demonstrate how one can use Pandat software and PanAl database to optimize the alloy chemistry and processing conditions to achieve the desired properties for aluminum alloys.

Application Examples

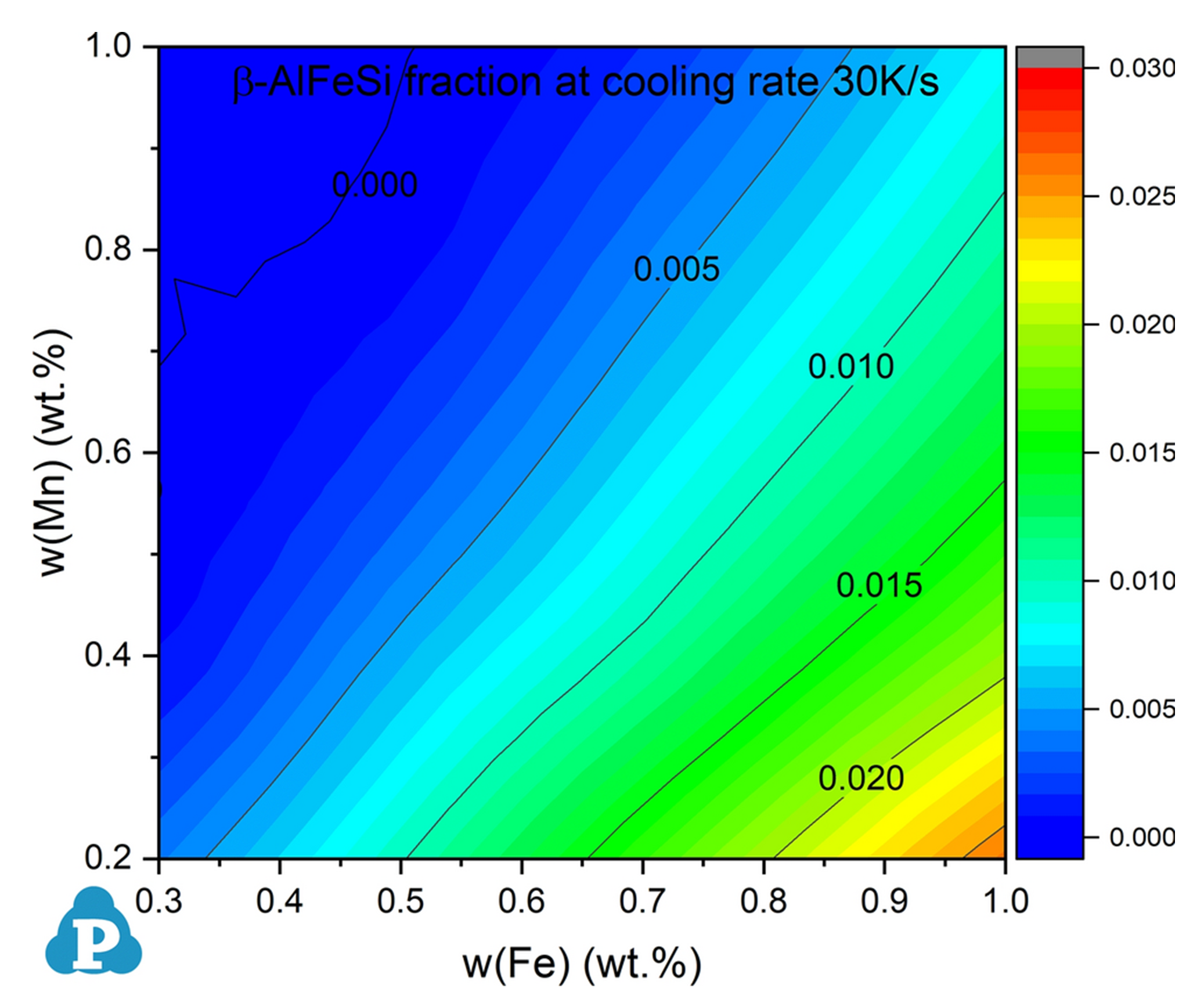

Predict the effect of alloy composition on the fraction of the β-AlFeSi phase in aluminum alloys

The β-AlFeSi phase is an undesirable Fe-bearing phase which may cause significant reduction in ductility due to its morphology. The addition of Mn can suspend the β-AlFeSi phase by promoting the formation of the α-AlFeSi phase. This figure displays a color map of the β-AlFeSi phase fraction as a function of the Fe and Mn compositions formed during solidification at a fixed cooling rate of 30K/s.

This type of color maps can be obtained through high-throughput calculation (HTC) feature in Pandat software. (Please refer J. Phase Equilib. Diffus., 41 (2020) 793-803 for details)

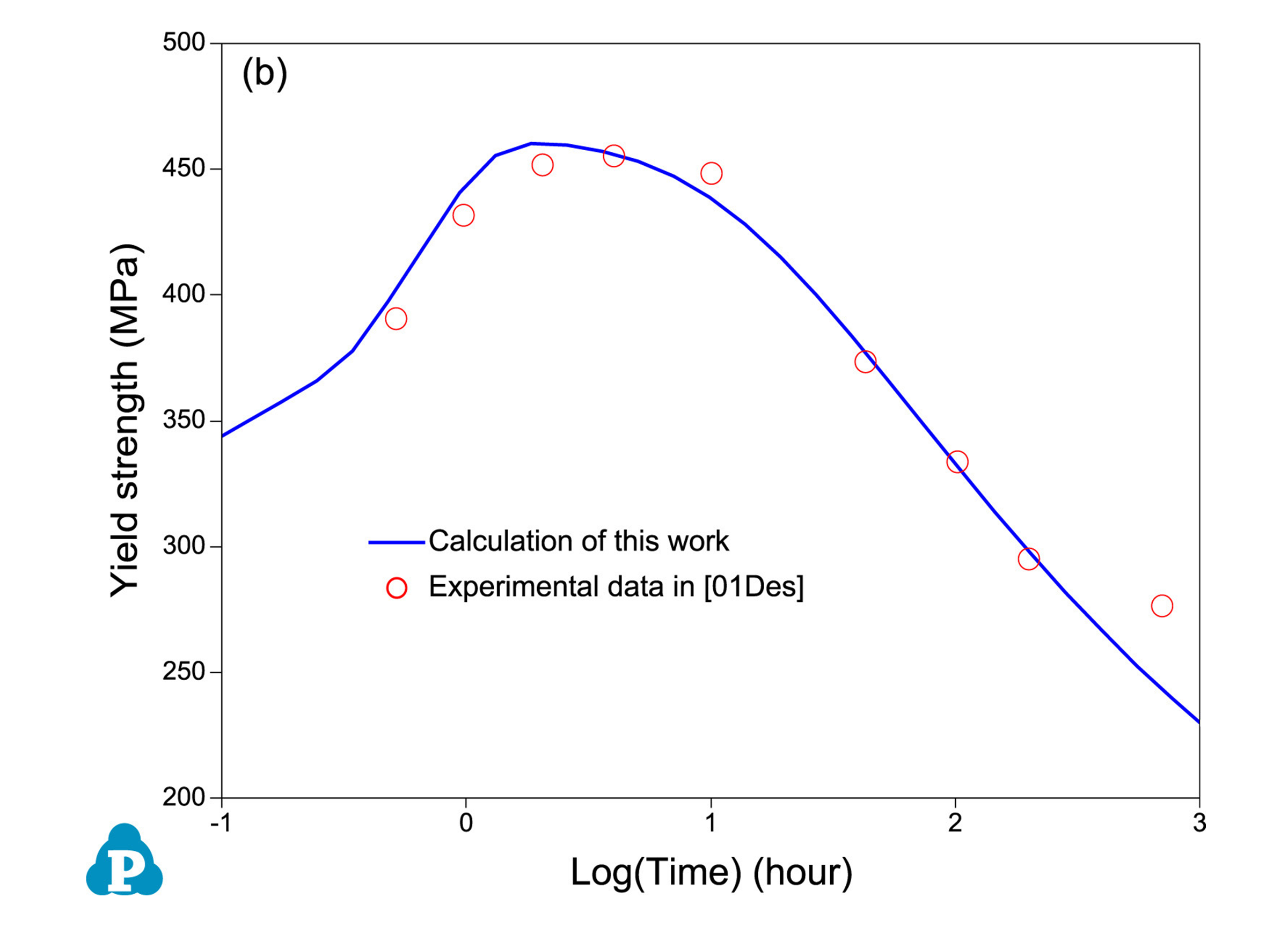

Precipitation kinetics of AA7xxx alloys

AA7xxx alloys, which use Mg and Zn as the major alloying elements, represent a group of the strongest Al alloys and are often used for high-strength applications. This figure shows the simulated yield strength of Al-2.3Mg-6.1Zn (wt.%) alloy aged at 160 °C for 1000 h using PanPrecipitation module.

(Please refer Calphad, 61 (2018) 246-263 for details)

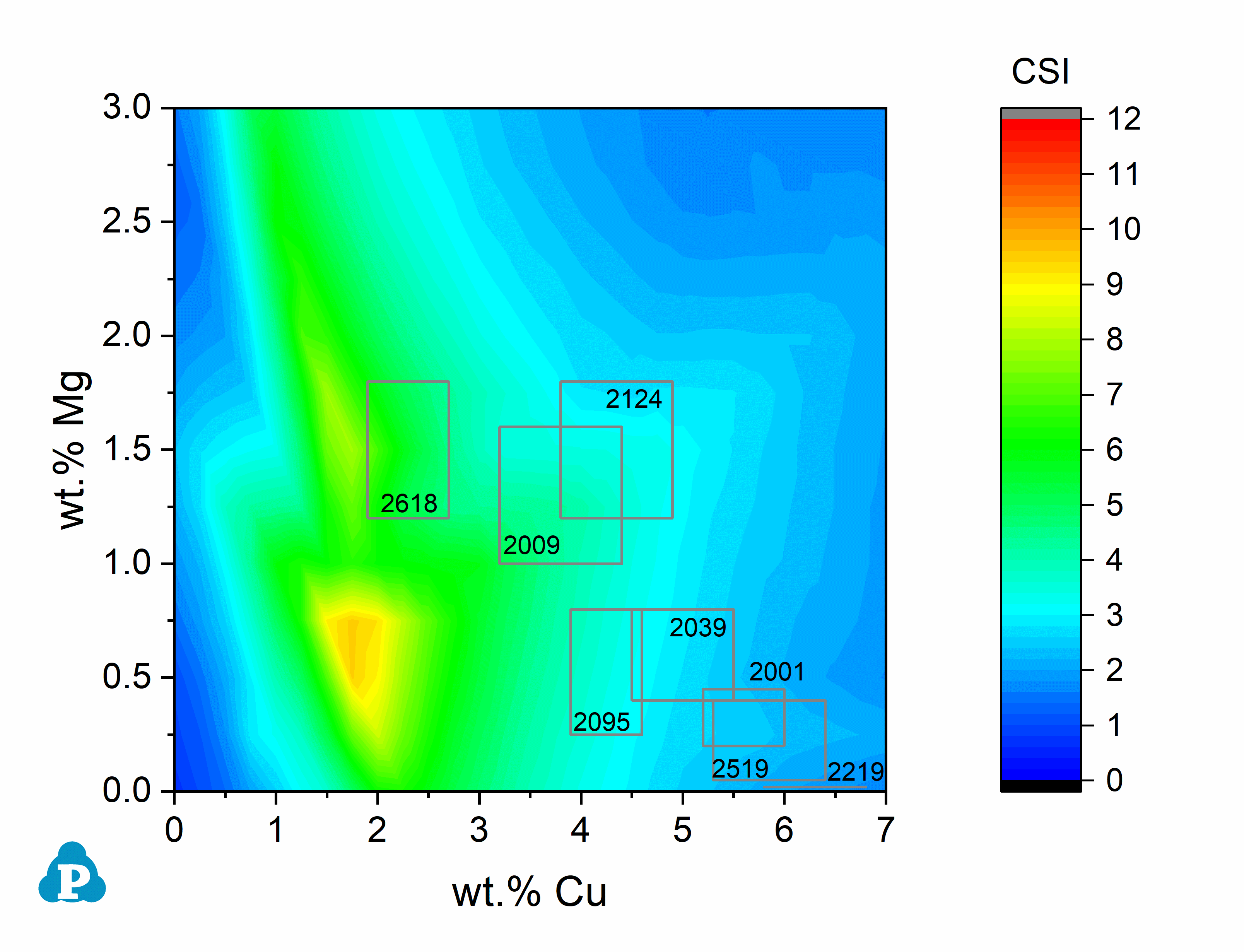

Prediction of Cracking susceptibility of commercial Al alloys during Solidification

The hot cracking susceptibility of Al alloys can be evaluated by the Cracking Susceptibility Index (CSI) as proposed by Prof. Sindo Kou (Acta Mater., 88 (2015) 366-374). The alloys with higher CSI values are more susceptible to cracking. This figure shows the CSI map for AA2xxx alloys with composition of Al-0.6Fe-0.5Mn-0.2Si-xCu-yMg. It is based on the high-throughput calculation results using PanSolidification module.

Please refer Metals, 11 (2021) 1479 for details.

Still have question? Contact us to find a solution for your applications.