Solutions for Titanium Alloys

Due to the high strength/weight ratio and good corrosion resistance, titanium and its alloys have found widespread use in the aerospace and chemical related industries. Technically, titanium alloys are usually classified as alpha (α), beta (β), and alpha-beta (α+β) alloys. In additional to the major alloying elements, such as Al, V, other alloying elements, as well as impurities, O, C, N are often included in titanium alloys. The properties of titanium alloys are very sensitive to the varied alloy chemistry, which is difficult to capture, especially for the minor alloying elements and impurities. Here we will use a few examples to demonstrate how one can use Pandat software and PanTi database to predict the composition effect. Applications of the simulation tools on additive manufacturing of titanium alloys are also demonstrated.

Application Examples

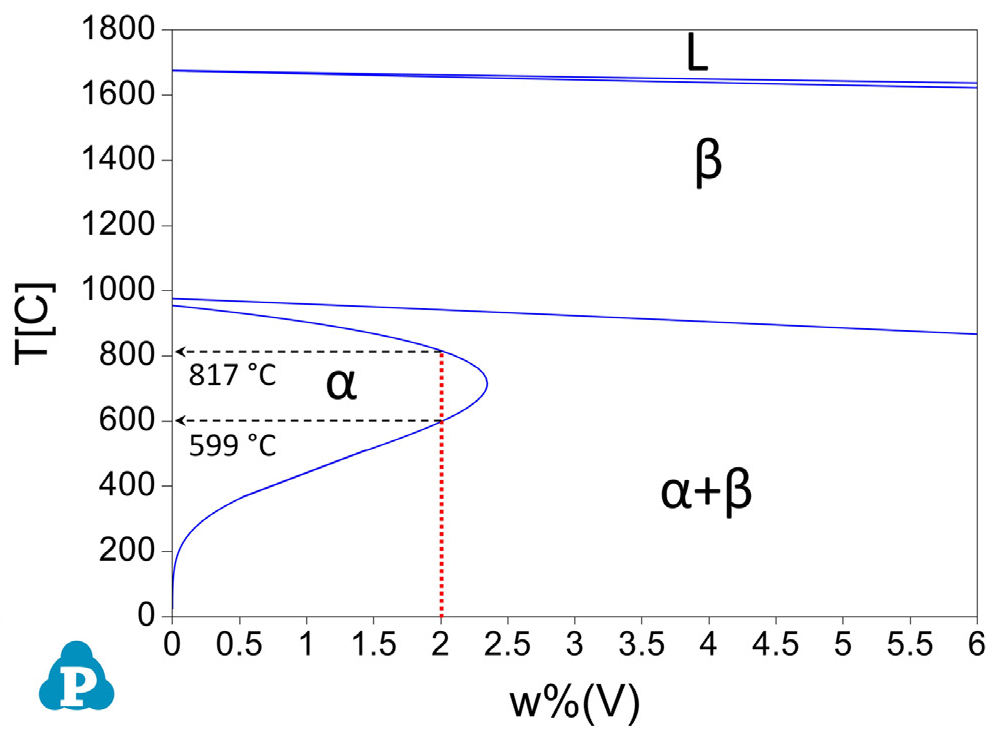

Understanding α-variant clusters in additively manufactured Ti-4Al-2V alloy

This figure shows the Pseudo-binary phase diagram of Ti4Al-(0-6)V (wt.%) section. The predicted retrograde zone provides an opportunity to produce a β-free α-Ti-4Al-2V alloy, which is validated by the XRD experimental results. The phase diagram is calculated using PanPhaseDiagram module with PanTi database. The calculated result helped researchers to identify the α-variant clusters in additively manufactured Ti-4Al-2V alloy. Please refer Lu et al, Scr. Mater., 212 (2022) 114578. for details.

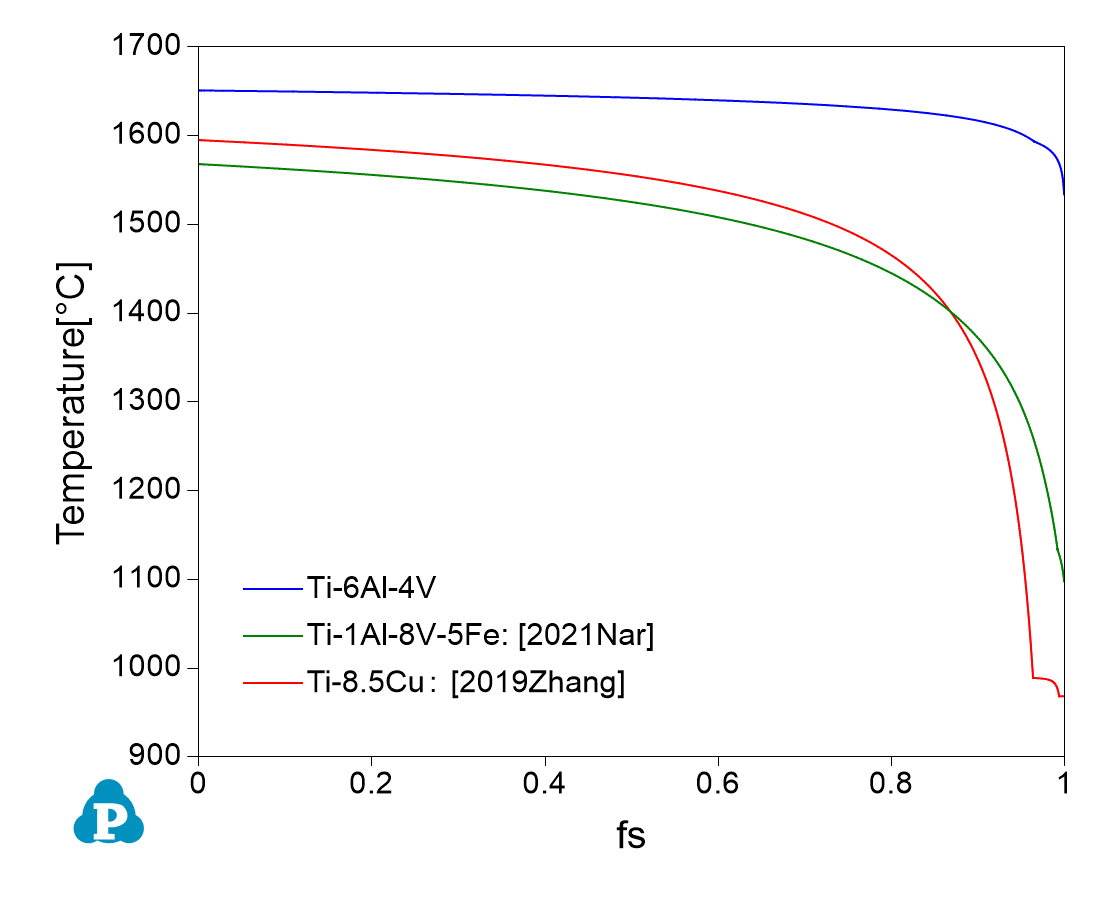

Additively manufactured high strength Ti alloys

This figure shows the solidification curves of three Ti alloys. Large columnar grains are observed in traditional Ti-6Al-4V alloys after additive manufacturing process due to its narrow solidification range. Finer scale equiaxed β grains are observed in the laser engineered net shaping (LENS) processed Ti-185 (Ti-1Al-8V-5Fe) alloy for a range of process parameters [2021Nartu]. Ultrafine-grained high-strength is achieved in Ti-8.5Cu alloy, which has the largest solidification range [2019Zhang]. The solidification range for a given alloy chemistry can be easily calculated by Pandat software and PanTi database, which can help the design of titanium alloys suitable for additive manufacturing. Besides the solidification range, the growth restriction factor Q, which can be calculated by Pandat, also plays key role on grain size refinement.

Please refer [2021Nartu]: Nartu et al, Mater. Sci. Eng. A, 821 (2021) 141627 and [2019Zhang]: Zhang et al, Nature, 576 (2019) 91-95 for details.

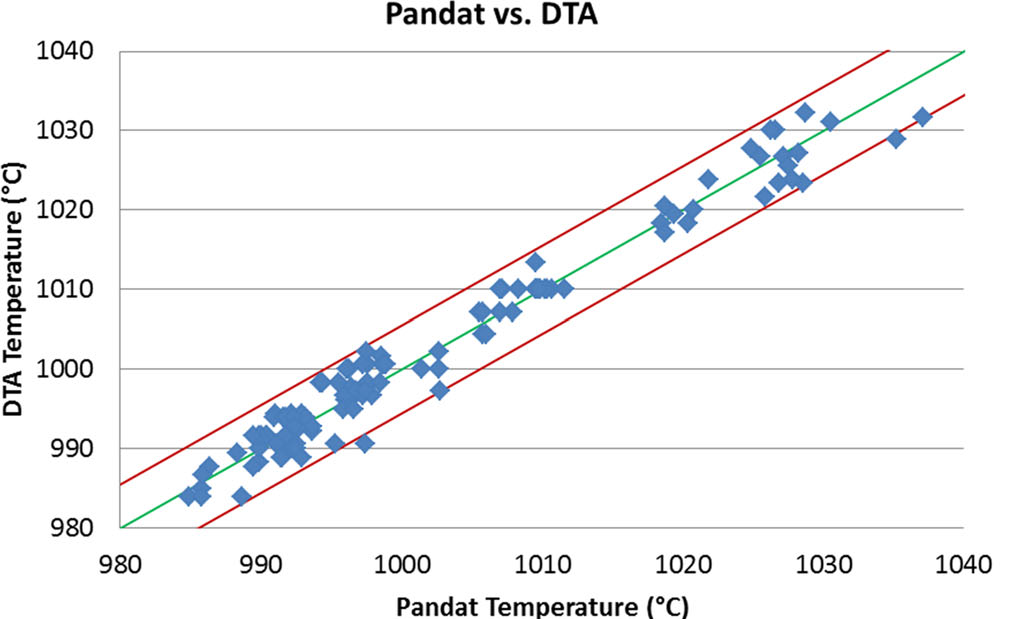

β Transus of Ti-6Al-4V alloy

The β Transus (βt ) temperature, at which α starts to form from β, is an important reference parameter in the selection of processing conditions, such as heat treatment process, for the conventional α-β type of titanium alloys. In this figure, the researchers compiled a series of DTA experimental results of βt temperature of Ti-6Al-4V alloys, and compared with Pandat calculation results using PanTi database. The calculated results show excellent agreement with DTA results. Their calculations further validated the reliability of PanTi database.

Please refer Rogoff, et al, J. Mater. Eng. Perform., 27 (2018) 5227-5235. for details.

Still have question? Contact us to find a solution for your applications.