Solutions for Nickel-based Superalloys

The Nickel-based superalloys have been widely used as high-temperature structural materials in gas turbine engine applications for many years. Ni-based superalloys are complex materials that typically contain 10 or more alloying elements. The excellent properties of these alloys can be obtained through optimizing the alloy composition and processing conditions, yet, it is extremely difficult to reach the goal by trial-and-error method for such complex materials. Here we will use a few examples to demonstrate how one can use Pandat software and PanNi database to predict the microstructure variation with respect to the alloy composition and heat treatment conditions, therefore, reach the target properties through accelerated design.

Application Examples

Microstructural stability of low-cost Ni-base superalloys

The prominent mechanical properties (such as high strength and creep rupture lifetime) at high temperatures (HTs) of Ni-base superalloys benefit primarily from their special coherent microstructures with spherical or cuboidal L12-γ′ (ordered Ni3Al phase) nanoprecipitates in the face-centered-cubic (FCC)-γ solid solution matrix

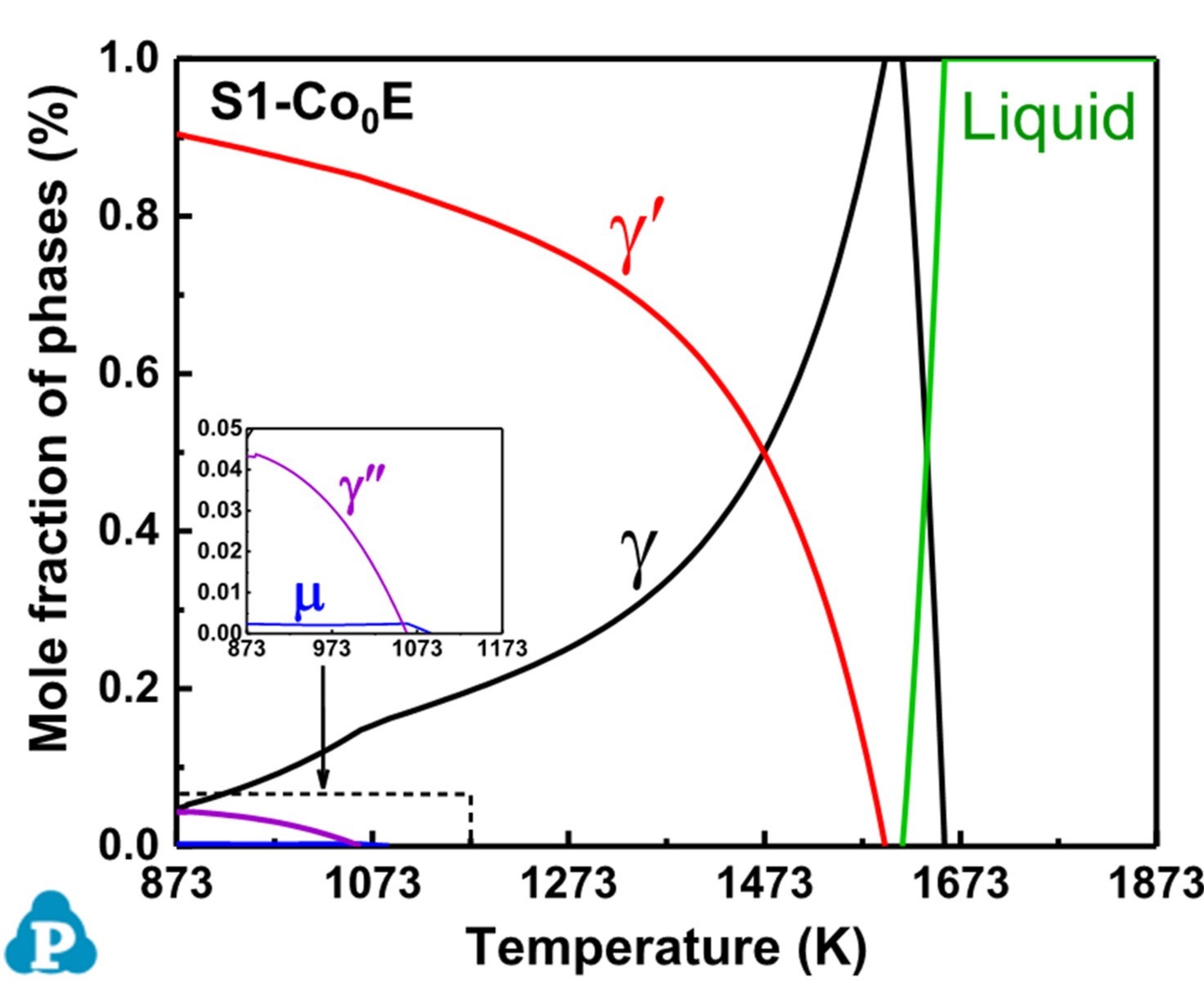

Using the PanPhaseDiagram module with the PanNi database, Sun et al. [2022Sun] investigated a series of low-cost Ni-base superalloys with a high volume fraction (f>70%) of γ′ precipitates. This figure shows the phase fraction evolution of one Co free Ni superalloy. The fraction of γ′ phase is higher than 70% at temperature lower than 1273 K. Such calculations allow users to quickly identify potential alloy compositions that meet the requirement of high volume fraction of γ′ precipitates.

Please refer [2022Sun]: Sun et al., Mater. Sci. Eng. A, 833 (2022) 142550. For details.

Co-precipitation Kinetics of γ′ and γ″ in Superalloy 718

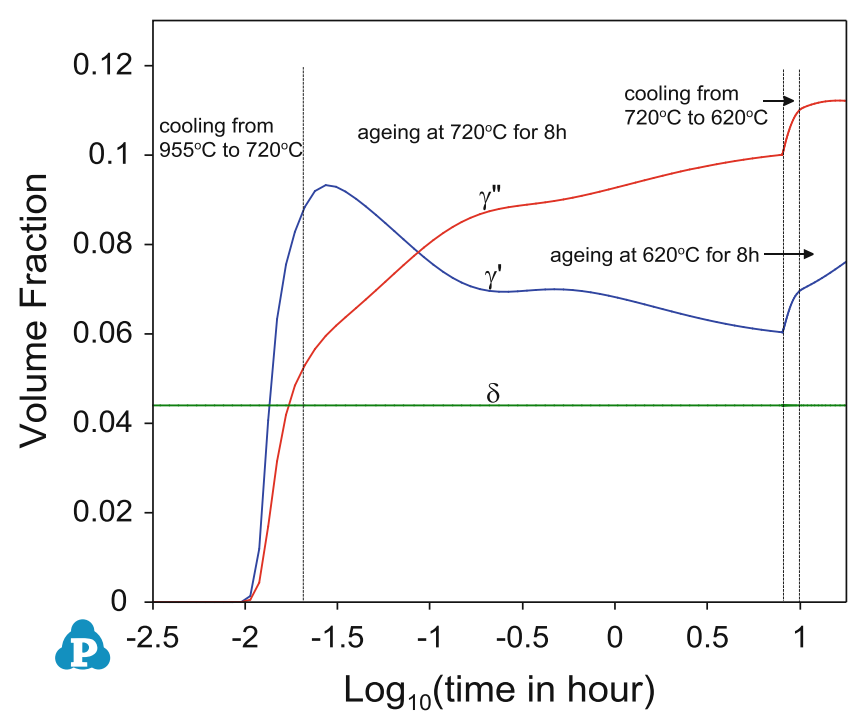

The strengthening mechanism of Superalloy 718 is unique due to the co-precipitation of ordered body center tetragonal DO22 γ″ and ordered L12 γ′ in the FCC γ matrix. The co-precipitation kinetics of phases in Superalloy 718 can be simulated in PanPrecipitation module with PanNi thermodynamic and mobility database. This figure shows volume fraction evolution of γ′ and γ″ during a typical two-step ageing process. Logarithm scale is used for time to reveal details at early stage, which shows that the γ′ precipitated quickly during quenching from 955 to 720 °C due to its coherence with the FCC matrix phase and the small interfacial energy between γ and γ′. However, most of the small γ′ particles re-solutionized during ageing at 720 °C. The γ″ particle, on the other hand, grows quickly during ageing at 720 °C.

Please refer Zhang et al. Proceedings of the 9th International Symposium on Superalloy 718 & Derivatives: (2018) 147-161 for details.

Unimodal to bimodal PSD transition of γ’ precipitates

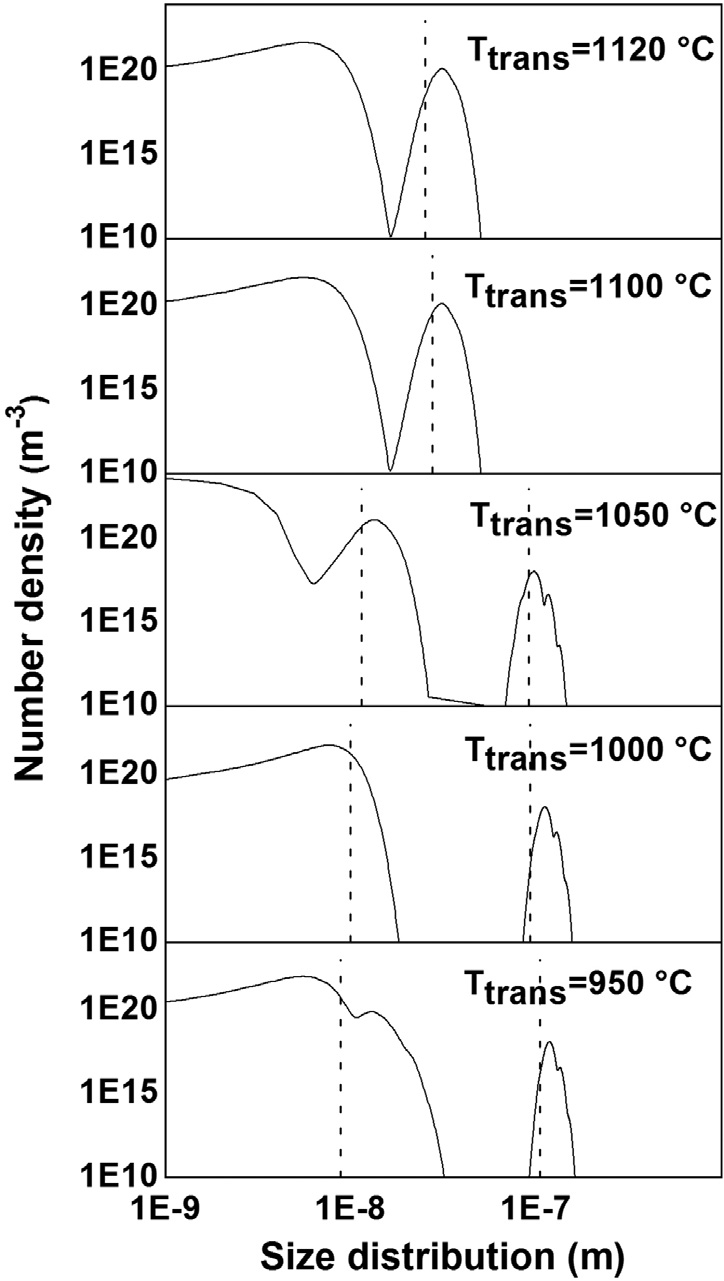

The excellent properties of Ni-based superalloys strongly rely on the characteristic parameters of γ’ precipitates, such as size, volume fraction, morphology and spatial distribution. During the two-step solution cooling method, the particle size distribution (PSD) of γ’ precipitates strongly depend on the transition temperature (Ttrans). This figure from Ref. [2020Deng] shows the precipitate size distribution simulated from PanPrecipitation module with varied transition temperatures. (a) 1120 °C, (b) 1100 °C, (c) 1050 °C, (d) 1000 °C and (e) 950 °C. The transformation from unimodal to bimodal PSD is predicted and is in good agreement with the experimental observation.

The alloy composition is Ni-26Co-13Cr-4Mo-4W-3.2Al-3.7Ti-0.95Nb-0.2Hf-0.05C-0.05Zr-0.025B (wt.%).

Please refer [2020Deng]: Deng et al, Scr. Mater., 183 (2020) 139-143 for detail.

Still have question? Contact us to find a solution for your applications.