Design of (Al3Ni+Al3Ti)/Al composite inoculant for improving the microstructure and mechanical properties of Zn-Al eutectoid alloy

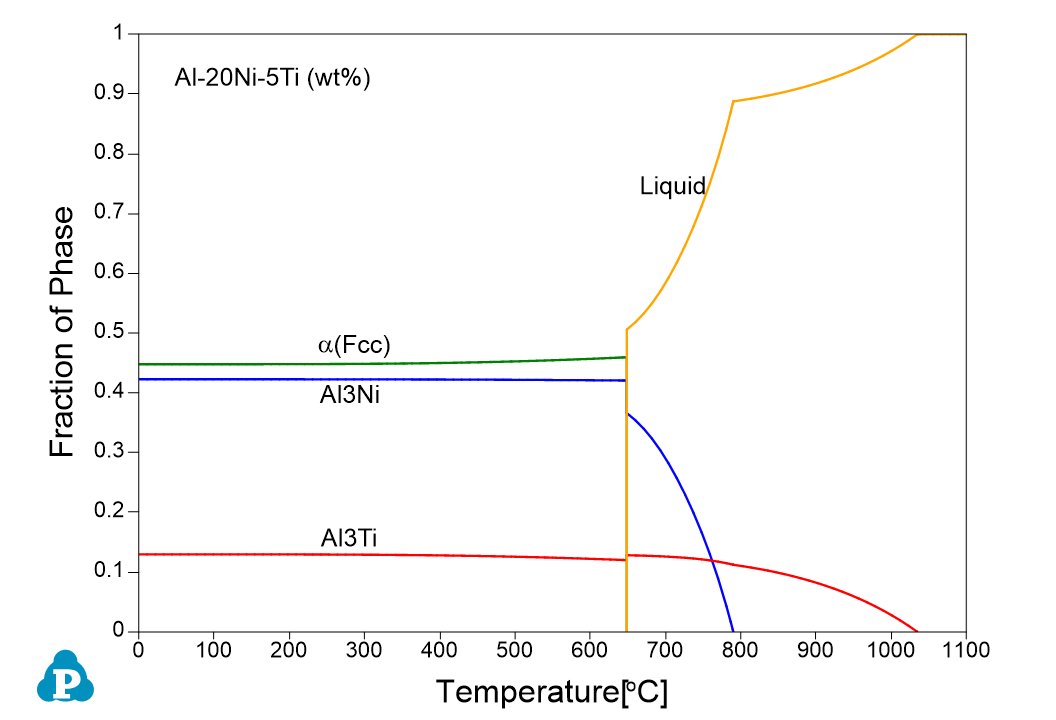

Inoculation is an approach commonly used to refine the grain size of the matrix phase, therefore improving the microstructure and properties of the materials. Yet, the improvement of mechanical properties is limited with the refinement effect only. In a recent study, (Metallurgical and Materials Transactions A, 2022), Zhang and colleagues designed a (Al3Ni+Al3Ti)/Al composite inoculant to improve the microstructure, damping and mechanical properties of Zn-Al eutectoid alloy (ZA22). It was found that Al3Ti particles acted as efficient heterogeneous nucleation centers of the α (Fcc) phase due to the excellent lattice match, but it cannot control the later grain growth. On the other hand, Al3Ni is more effective in controlling the growth of the α phase and at the same time acting as hardening particles. It was found that it is the unique combined effect of the Al3Ti and Al3Ni particles that makes the in situ (Al3Ni+Al3Ti)/Al composite inoculant an efficient refiner for the ZA22 alloy. In their work, the alloy composition of the inoculant is selected in the Al-Ni-Ti system so that both Al3Ti and Al3Ni should form and the volume fraction of the Al3Ni particles should be significantly higher than that of the Al3Ti particles. Through the help of Pandat software and the PanAl database, they were able to identify an alloy Al-20Ni-5Ti (wt%) for such a purpose.

The Figure shows an equilibrium calculation for the Al-20Ni-5Ti (wt%) alloy using Pandat software and PanAl database. As indicated in the paper by Zhang et. al., the calculated results agree with the experimental observations, which aided the design of the innovative (Al3Ni+Al3Ti)/Al composite inoculant.

References:

J. Zhang, F. Yin, B. Jiang, Q. Wang, H. Yu, Z. Jiao, L. Liu, P. Ji, Y. Liu, A Novel In Situ (Al3Ni + Al3Ti)/Al Composite Inoculant and Its Effects on the Microstructure, Damping and Mechanical Properties of Zn–Al Eutectoid Alloy, Metall. Mater. Trans. A, 53 (2022) 2099-2115. doi:10.1007/s11661-022-06652-y.

Publications related to different topics