Design of ultra-ductile magnesium alloys as bioabsorbable implant materials

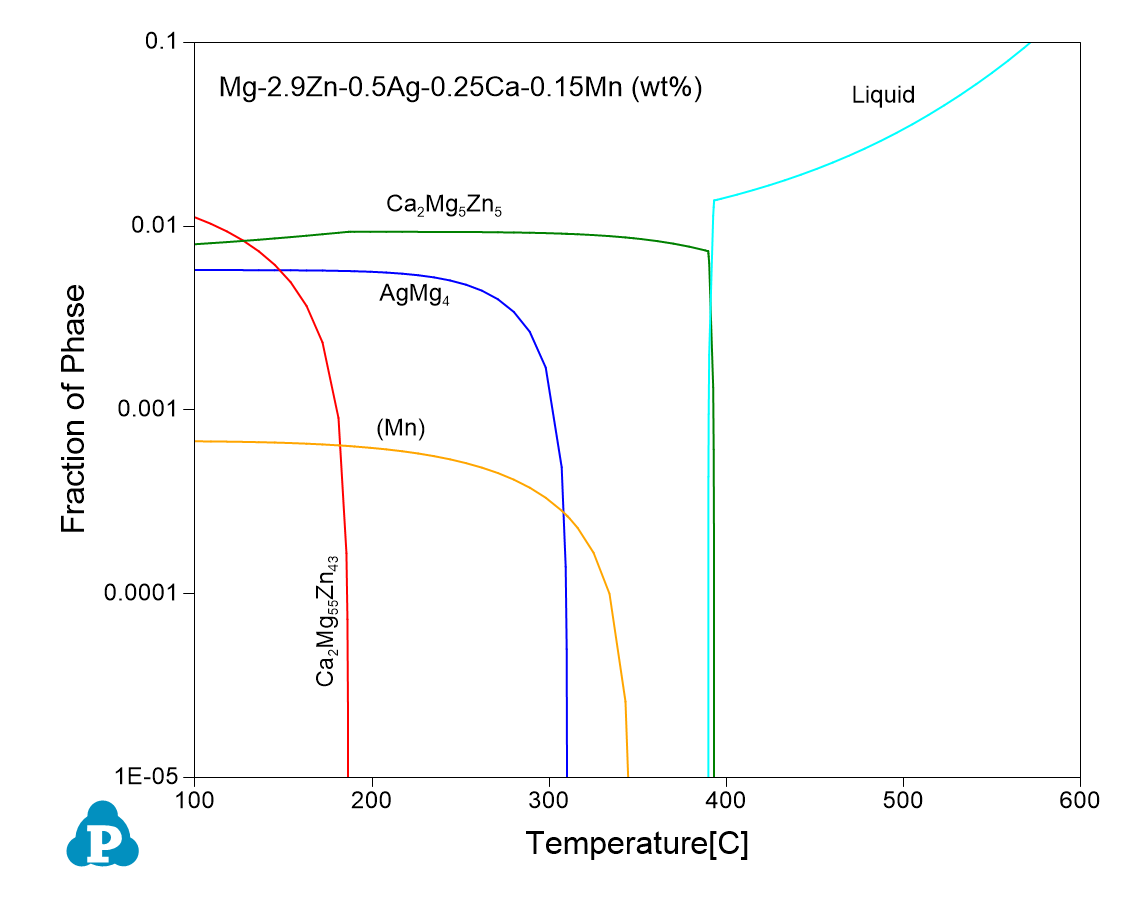

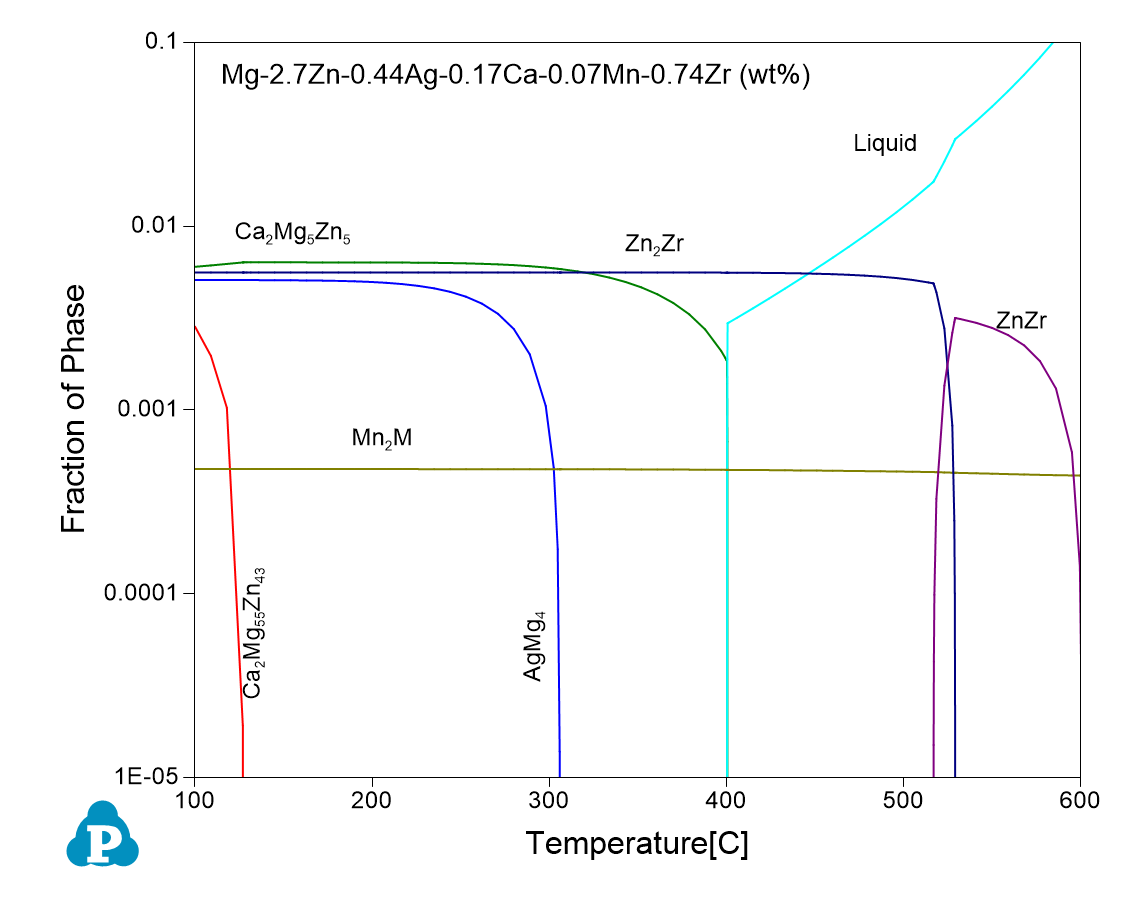

Mg alloys have been widely used in automotive and aerospace industries due to their density advantage. In addition, Mg alloys also have potential applications in the field of medical implant due to their biocompatibility and biodegradability. In the work published by Hänzi et. al., (Philos. Mag. Lett, 2009) and later reviewed by Schmid-Fetzer (Calphad, 2018), CALPHAD method was used to aid the design of Mg alloys for such a purpose. Due to the special application, the choice of alloying elements is restricted to those harmless to the human body. A microalloying concept was chosen for the desired pinning of grain boundaries by second phase particles and to prevent the formation of coarse intermetallic phase particles. In addition, grain growth should also be restricted. The design concepts lead to the selection of Zn, Ag, Ca, Zr and Mn. Two alloys, denoted here as ZQX3 (Mg-2.9Zn-0.5Ag-0.25Ca-0.15Mn) and ZKQX3 (Mg-2.7Zn-0.74Zr-0.44Ag-0.17Ca-0.07Mn) were studied by Hänzi et. al. In their work, the concepts of microalloying design, the extrusion temperature selection, and the grain size optimization are all guided by the calculations using Pandat software and PanMg database. The figures show the effect of micro-alloying. Small amount of Zr leads to the formation of ZnZr and Zn2Zr at higher temperatures.

References:

A.C. Hanzi, at el, Design strategy for microalloyed ultra-ductile magnesium alloys, Philos. Mag. Lett., 89 (2009) 377-390. doi:10.1080/09500830902960125.

Schmid-Fetzer and F. Zhang, “The light alloy Calphad databases PanAl and PanMg”, Calphad, 61 (2018), 246-263. doi:10.1016/j.calphad.2018.04.006.

Publications related to different topics