Designing a medium-entropy alloy strengthened and ductilized by bifunctional nanoprecipitates

Single-phase high- and medium-entropy alloys with face-centered cubic (fcc) structure can exhibit high tensile ductility and excellent toughness, but their room-temperature strengths are low. In a recent publication (Nature, 2021), Yang and her colleagues developed an Fe-Ni-Al-Ti medium-entropy alloy through alloy design using the CALPHAD method. Three main criteria were considered in their alloy design process. First, the alloy needs to have a fcc matrix containing 20 to 30 mol% of ductile L12 precipitates for strengthening. Second, the alloy should contain only L12 precipitates and not any potentially embrittling intermetallic phases. Third, the matrix composition should be such that, when cooled quickly to room temperature, it should undergo a transformation to bcc-martensite. With these design criteria, they were able to design an alloy in which the L12 nanoprecipitates are used to enhance both the strength and ductility. Calculations of phase equilibria were performed using Pandat software.

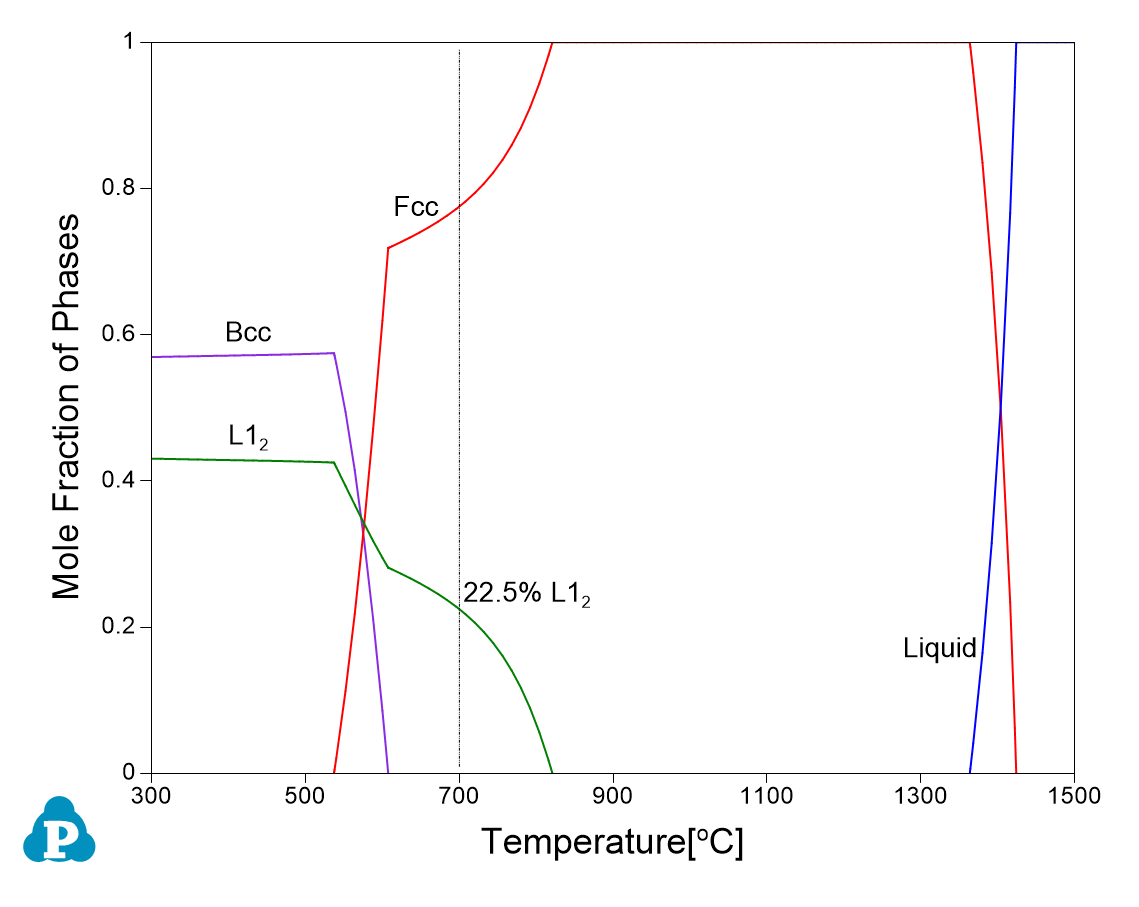

A line calculation is performed for the alloy selected by Yang et al., Fe-32.6Ni-6.1Al-2.9Ti (at%), using Pandat software and PanHEA database in the temperature range 300-1500°C. Although not identical, similar results are obtained. At the ageing temperature (700°C), 22.5% of L12 phase is predicted.

References:

Y. Yang, et al., Bifunctional nanoprecipitates strengthen and ductilize a medium-entropy alloy, Nature, 595 (2021) 245-249. doi:10.1038/s41586-021-03607-y.

Publications related to different topics