Eliminate the formation of detrimental phase in casting aluminum alloy A356

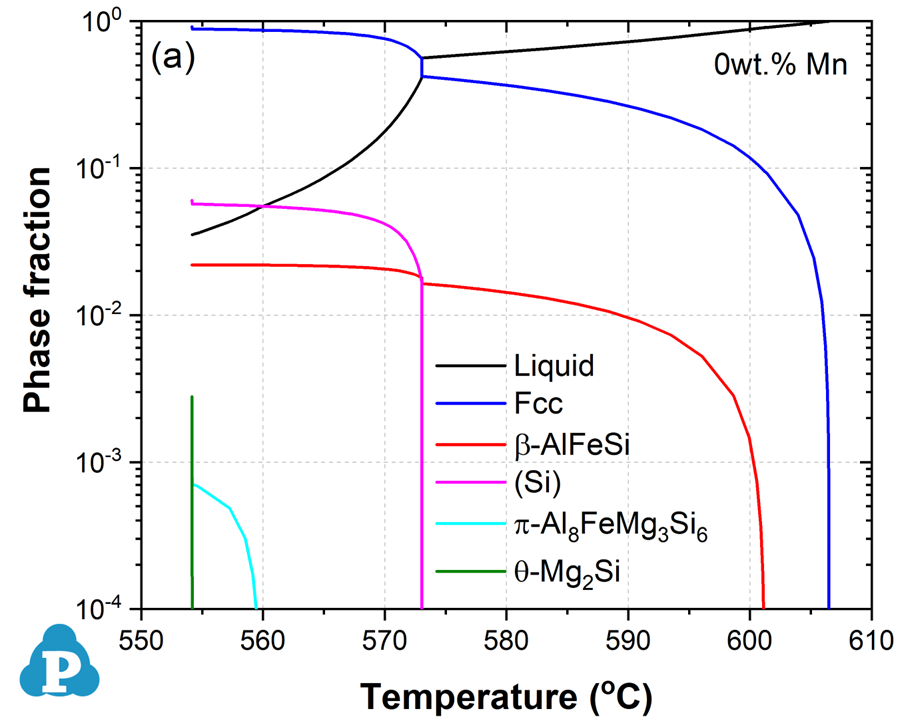

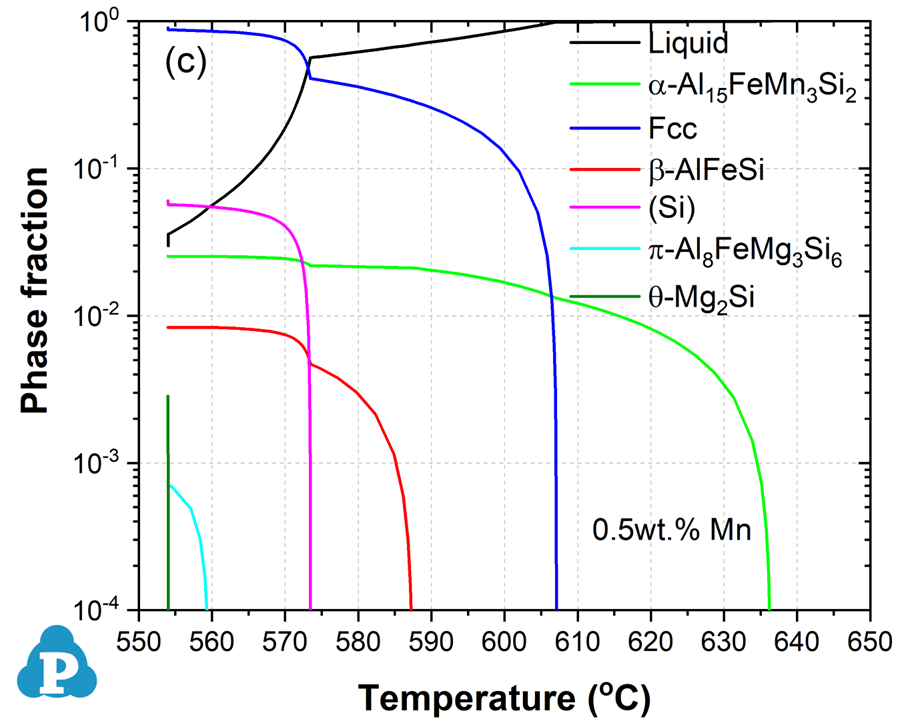

Al-Si based casting alloys are widely used in automobile and aerospace industries due to their high strength-to-weight ratio, good ductility and corrosion resistance and excellent castability. A356 (nominal composition: Al-7Si-0.3Mg) is a popular alloy of this category. In addition to Si and Mg, other elements with minor amounts also appear in A356. While some minor alloying elements are added to improve the properties of this class of alloys, other impurity elements must be eliminated to avoid the formation of detrimental phases. Fe is one of the common impurities in Al-Si based alloys and could be detrimental due to the formation of brittle β-AlFeSi phase. On the other hand, the α-AlFeSi phase which has a more compact Chinese script morphology improves the ductility of the Al-Si based alloys. In a recent publication (J. Phase Equilib. Diffus., 2020), Zhang and colleagues demonstrated that simulation approach can be used to study the correlation between casting microstructure features and the alloy composition and cooling rate. Such simulations can therefore help develop targeted casting microstructure and reduce the formation of detrimental phases. Solidification simulation is performed with Scheil model for the Al-8Si-0.35Mg-0.7Fe (wt.%) alloy with varied Mn contents. It is seen that both the formation temperature and the volume fraction of β-AlFeSi is significantly reduced due to the addition of Mn, while the formation of α-Al15(Fe,Mn)3Si2 is promoted.

References:

F. Zhang, et al., Simulation of the Composition and Cooling Rate Effects on the Solidification Path of Casting Aluminum Alloys, J. Phase Equilib. Diffus., 41 (2020) 793-803. doi:10.1007/s11669-020-00834-0.

Publications related to different topics