Sintered nanostructured alloys for advanced fusion energy applications

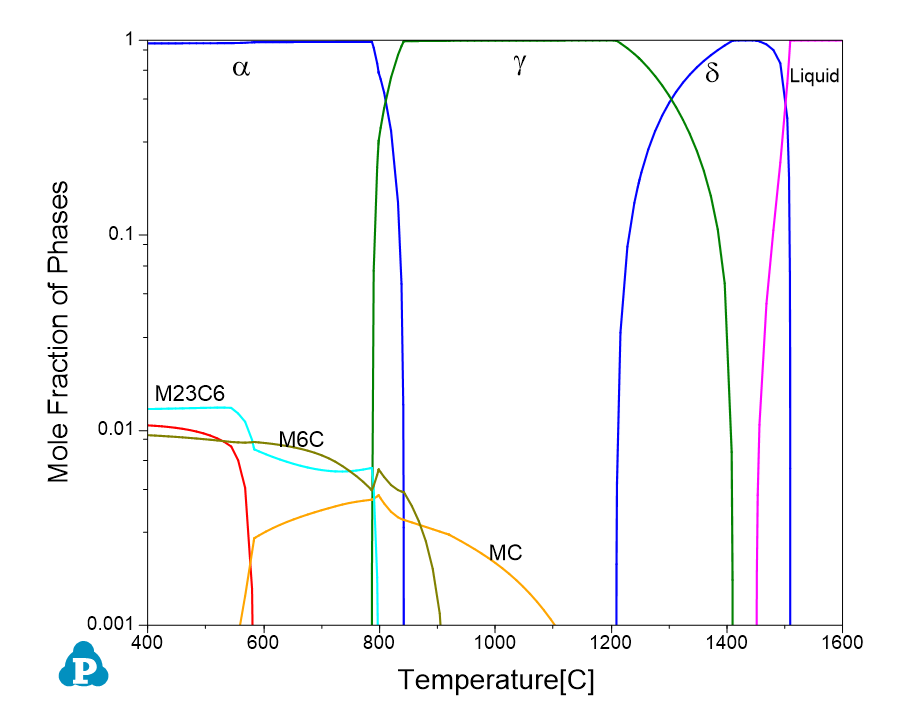

Materials used in fusion devices must withstand simultaneous exposures to high heat flux, particle bombardment, and intense bulk neutron irradiation environments. Developing advanced structural materials for nuclear applications has always been an active research topic. Reduced-activation ferritic martensitic (RAFM) steels have been developed for such applications, and castable nanostructured alloys (CNA) recently developed are a novel class of RAFM steels with improved performance in extreme environments. CNAs are engineered with a high-density of dispersed nano-scaled metal-carbide and metal-nitride precipitates. In a recent publication (Journal of Nuclear Materials, 2023), Sprouster and colleagues demonstrated their efforts to optimize RAFM steels by mimicking the microstructure of CNAs. Through the combination of computational thermodynamics, characterization, and mechanical testing, this work successfully demonstrated the applicability of sintering to CNA fabrication. Pandat software and PanFe database were used to perform the equilibrium calculation to predict the phases and phase fractions at different sintering temperatures. The Figure shows equilibrium calculation for Fe-8.77Cr-1.46W-0.57Mn-0.08V-0.05Ta-0.13Ti-0.1Si-0.09C (wt%) alloy in the temperature range 400-1600°C.

References:

D.J. Sprouster, et al., Sintered nanostructured alloys for advanced fusion energy applications, J. Nucl. Mater., 586 (2023) 154683. doi:10.1016/j.jnucmat.2023.154683.

Publications related to different topics